A fracturing method for sub-stage circulation of low-pressure forward injection of low-temperature fluid in upward drilling

A low-temperature fluid, advancing technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as weakening thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below.

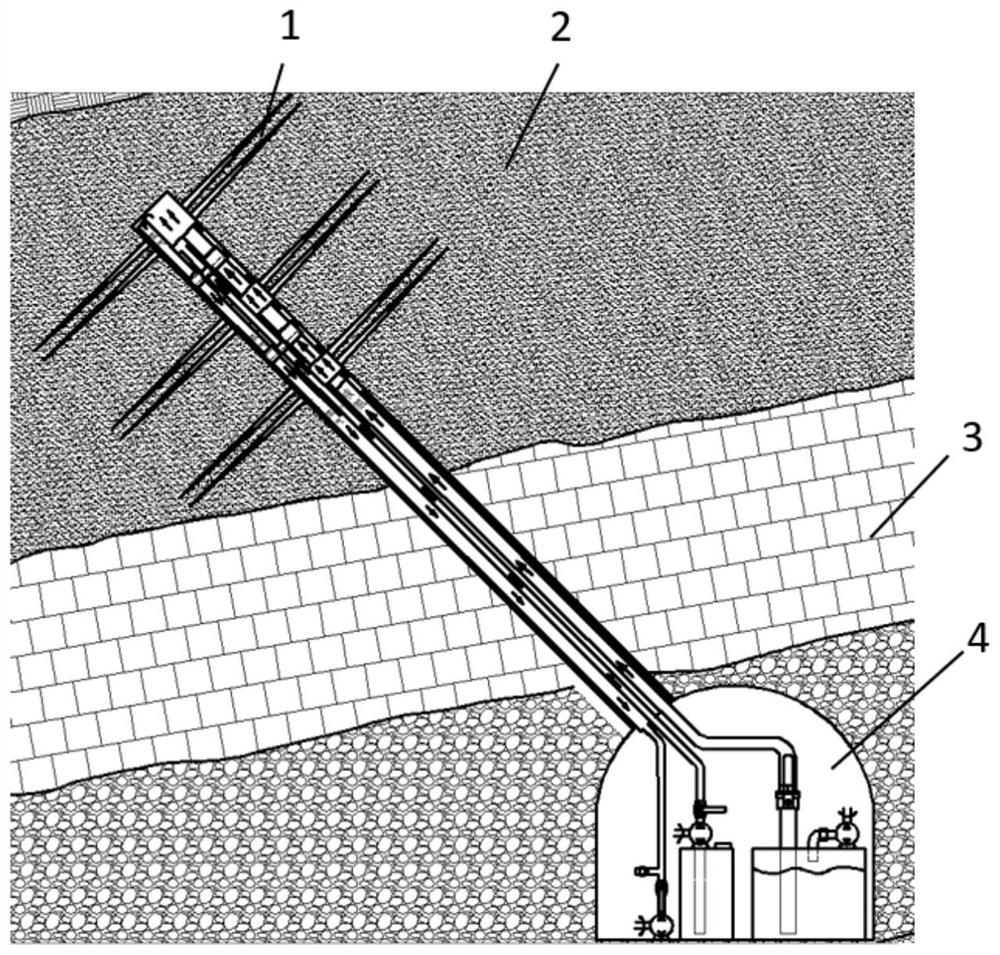

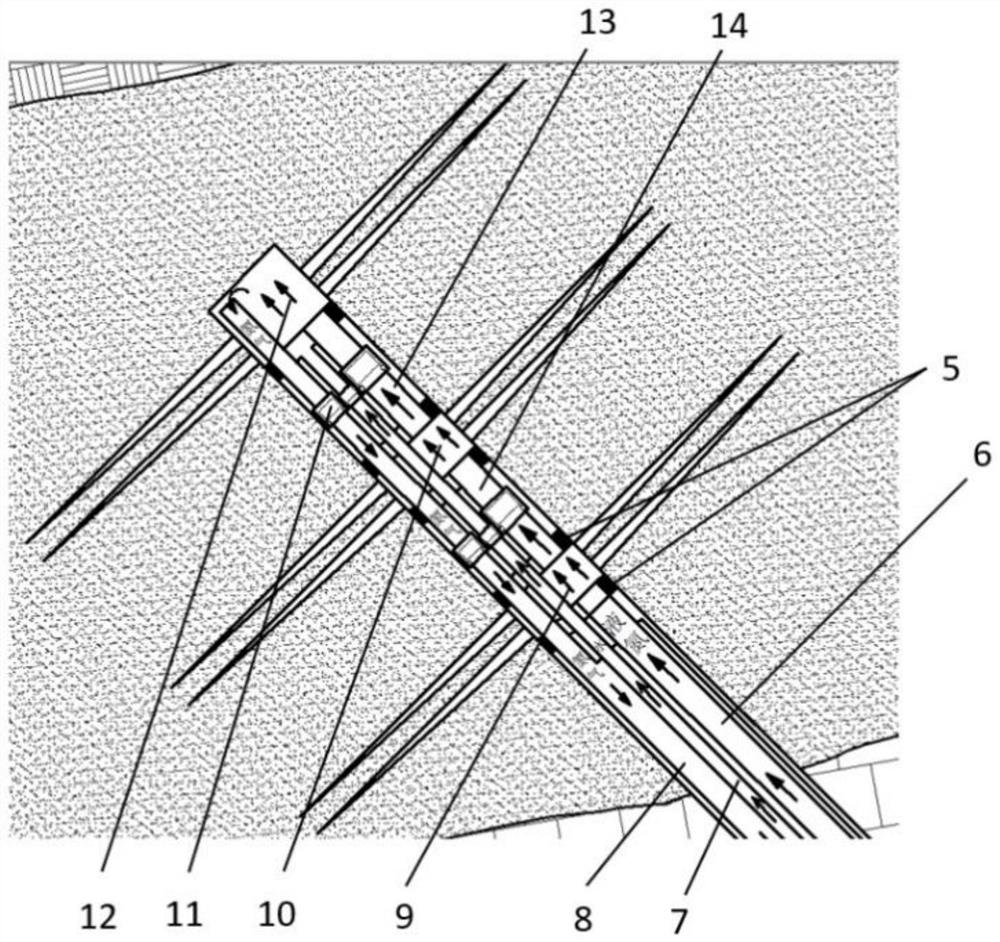

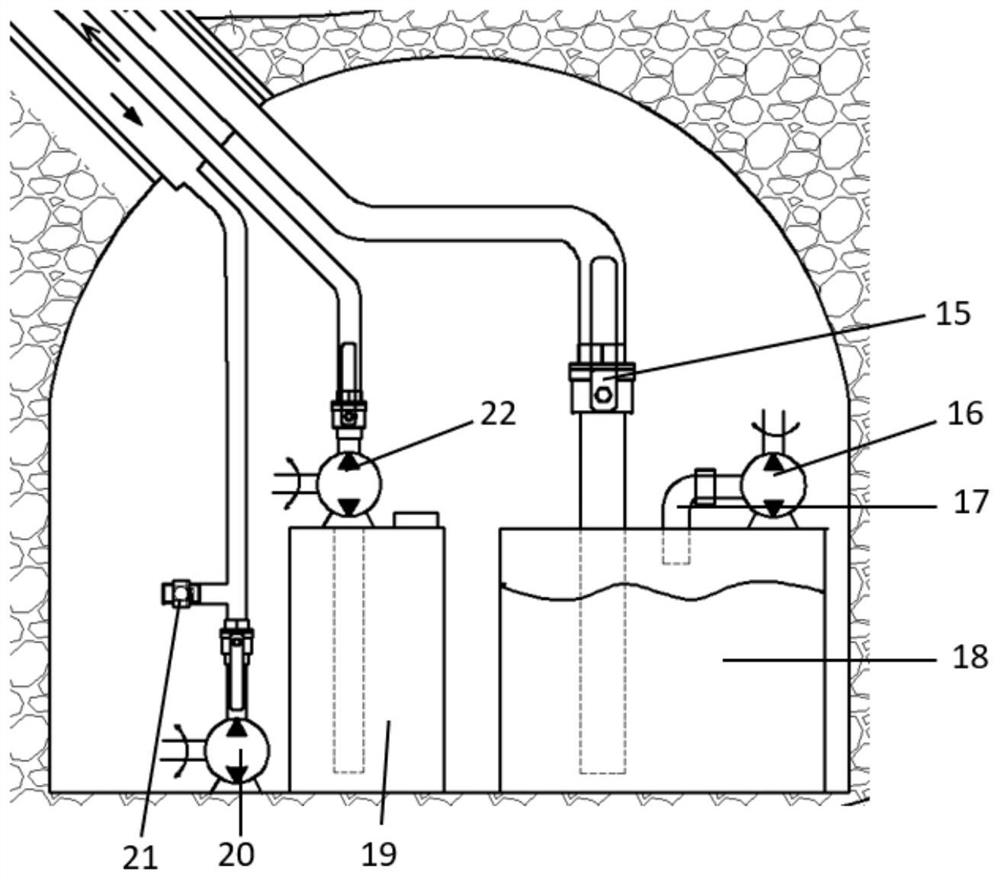

[0023] Such as Figure 1 to Figure 3Shown, concrete steps of the present invention are:

[0024] A. First, extend the water jet slotting equipment into the upward drilling, and cut out three crack areas 1 at equal intervals along the direction perpendicular to the upward drilling with the axis of the upward drilling as the center. the fracture zone, the second fracture zone and the third fracture zone;

[0025] B, the phase-change gas discharge channel 8 is set, the phase-change gas discharge channel 8 is made up of an inlet section, a diameter-changing section and an exhaust section, and one end of the inlet section and one end of the exhaust section are connected to the two ends of the diameter-changing section respectively. The gas section is composed of a plurality of round pipes connected at the first place and connected by a quick-plug joint 11. From the other end of the exhaust section, three sets of hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com