Block self locking and destructing safety type syringe

A safe, syringe technology, applied in the field of medical devices, can solve the problems of difficult to achieve blockage, cannot be used normally, and difficult to process, and achieve the effects of reducing residual flow, good effect, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

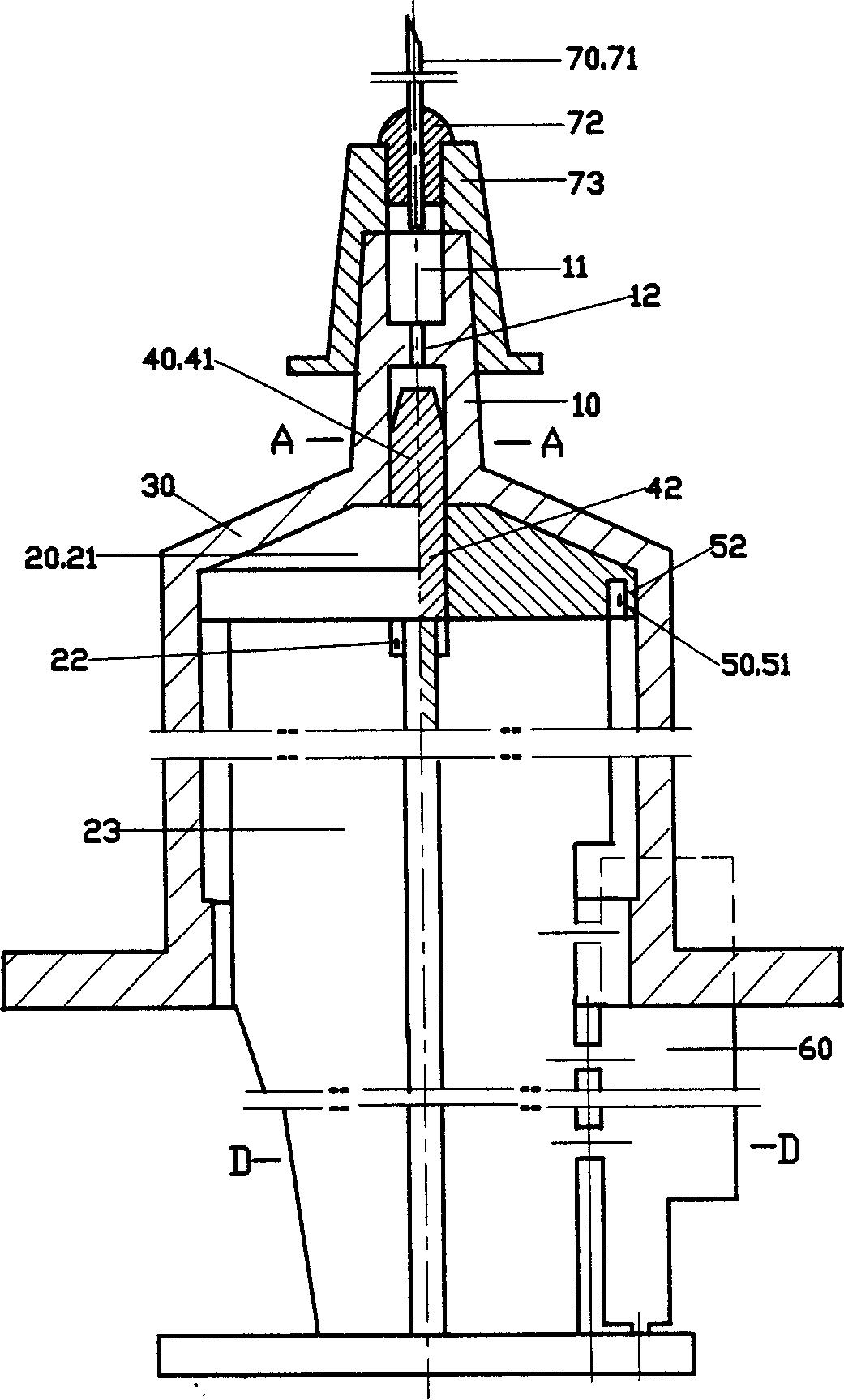

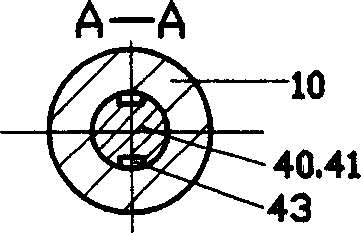

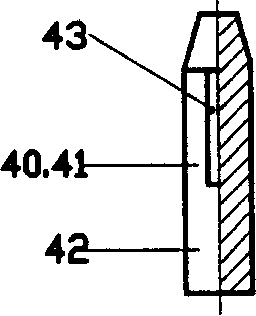

[0067] See Figure 1 to Figure 8 , The material used in the syringe of this embodiment complies with the national standard. The syringe of this embodiment has a conical head 10, a mandrel 20 and a jacket 30; the conical head 10 has a conical head hole 11, and the conical head 10 and the jacket 30 are integrated; the mandrel 20 is an integral piece with a top 21 and a shaft 23 The syringe also has a blocking body 40, the blocking body 40 is provided with a blocking portion and a positioning portion 42, the blocking portion of the blocking body 40 can be matched with the taper hole 11 or the blocking portion of the blocking body 40 can be connected with the blocking cavity 31 of the overcoat 30 matched; the top 21 of the core rod 20 is provided with an elastic sealing structure 50; see figure 1 , Figure 4 , Figure 5 and Figure 6 , the elastic sealing structure 50 of the top 21 of the core rod 20 is composed of an elastic groove 51 and a sealing ring 52, the elastic sealin...

Embodiment 2

[0071] See Figure 9 to Figure 10 The opening direction of the elastic groove 51 of the elastic sealing structure 50 of the syringe of the present embodiment is upward; the liquid guide hole on the anti-stab part 12 is set eccentrically; the syringe of the present embodiment has the positive effect of strengthening the blocking and self-locking injection passage. Effect: see Figure 9 and Figure 10 , the cone head hole 11 is a stepped hole, and the plugging portion 41 of the plugging pin 40 is provided with a closed boss 44, and the outer diameter of the joint between the sealed boss 44 and the stepped hole section of the cone head hole 11 is larger than that of the cone head The inner diameter of the stepped hole section of hole 11 is 0.5 mm; see Figure 10 , after the injection is completed, the blocking part 41 and the sealing boss 44 cooperate with and seal the stepped hole section of the taper hole 11, so as to achieve the purpose of strengthening the blocking and self...

Embodiment 3

[0073] See Figure 11 to Figure 13 , the needle tube 71 of the syringe of the present embodiment is fixed with the cone 11 and the overcoat 30 as one piece; the inner wall of the cone hole 11 does not have the anti-poking part 12; the sealing effect of the elastic sealing structure 50 of the syringe of the present embodiment is remarkable, and has Reduce the effect of resistance when pushing and pulling the core rod 20: see Figure 11 and Figure 13 , the elastic sealing structure 50 of the top 21 of the core rod 20 is composed of an O-ring 53 and a sealing ring positioning part 54; the sealing ring positioning part 54 of the elastic sealing structure 50 is integrated with the top 21 of the core rod 20; the elastic sealing structure The O-shaped sealing ring 53 of 50 is set and fixed on the sealing ring positioning part 54; the outer wall of the O-shaped sealing ring 53 can be matched with the inner wall of the outer casing 30, and the outer wall of the O-shaped sealing ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com