Oil pipe continuous injection device, injection method andoil pipe changing method without stopping pump

A technology of injection device and oil pipe, which is applied in the direction of wellbore/well valve device, earthwork drilling and production, cleaning equipment, etc., and can solve the problems of easy settlement of suspended sand, scrapping of oil well, and restrictions on popularization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

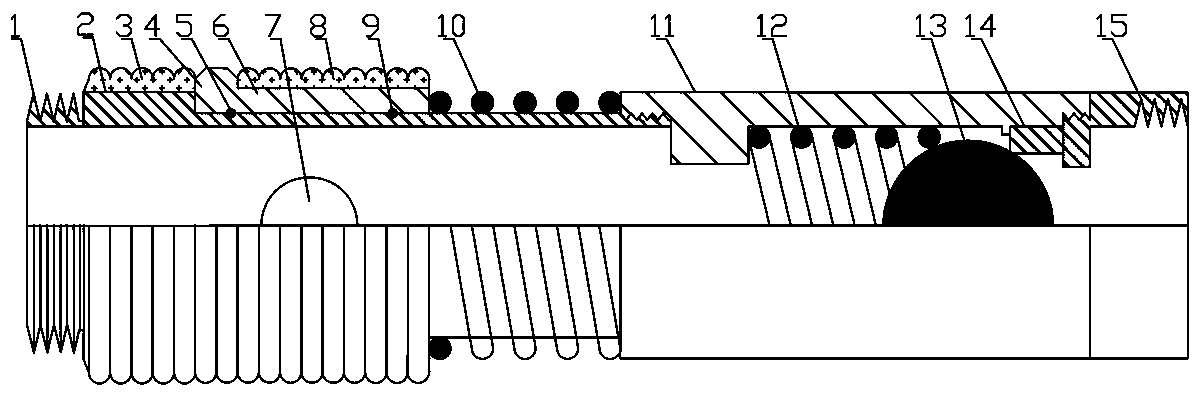

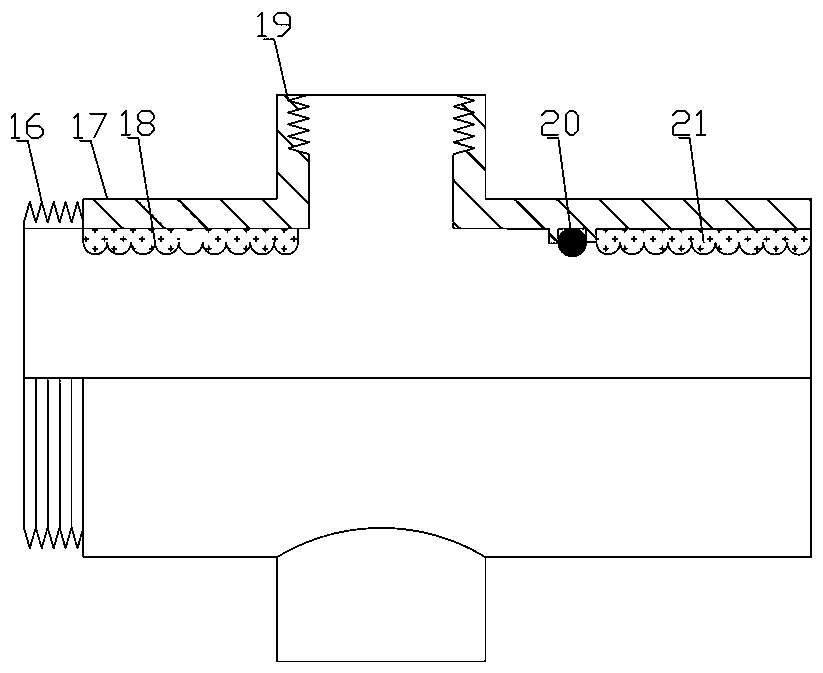

[0027] A continuous tubing injection device, comprising a main body seat 17 and a main pipe body 2 sleeved in the main body seat 17; wherein, the main body seat 17 is provided with a wellhead connection end 16 and an injection pipeline connection end 17, and the main body seat 17 is connected to the wellhead; The main body 2 is a round pipe; the two ends of the main body 2 are provided with an upper joint 15 and a lower joint 1 for connecting oil pipes, the main body 2 is provided with a liquid inlet hole 7, and the main body 2 is sleeved with a sliding opening. Closing device; the sliding opening and closing device includes a sliding sleeve main body 6 and a sliding sleeve return spring 10, and the end of the sliding sleeve main body away from the sliding sleeve returning spring 10 is provided with a sliding sleeve opening and closing gear; the main body seat is provided with a sliding sleeve The sleeve opening and closing gear is matched with the elastic steel ring used to co...

Embodiment 2

[0029] A continuous oil pipe injection method, using the oil pipe continuous injection device as described above, the method is as follows:

[0030] The main body seat 17 is connected to the wellhead through the wellhead connection end 16, and the injection pipeline is connected to the injection line connection end 17; the upper oil pipe is connected to the upper joint 15, and the lower oil pipe is connected to the lower joint 1; the upper oil pipe is connected to the injection line, and the lower oil pipe passes through the main seat 17 lowered into the well;

[0031] In the initial downward stage of the main body 2, the valve ball 11 receives the force of the valve ball return spring 12, and the contact and seal between the valve ball 13 and the valve seat 14; when the well cleaning fluid is injected through the built-in channel of the upper oil pipe, the pressure of the well cleaning fluid When it is greater than the spring force of the valve ball return spring 12, the valv...

Embodiment 3

[0035] A method for changing oil pipes with non-stop pumps, using the above-mentioned oil pipe continuous injection device, the method is as follows:

[0036] The main body seat 17 is connected to the wellhead through the wellhead connection end 16, and the injection pipeline is connected to the injection line connection end 17; the upper oil pipe is connected to the upper joint 15, and the lower oil pipe is connected to the lower joint 1; the upper oil pipe is connected to the injection line, and the lower oil pipe passes through the main seat 17 lowered into the well;

[0037] In the initial downward stage of the main body 2, the valve ball 13 is under the force of the valve ball return spring 12, and the contact between the valve ball 13 and the valve seat 14 is sealed; When it is greater than the spring force of the valve ball return spring 12, the valve ball 13 is pushed back, so that the valve ball return spring 12 is elastically deformed, the one-way valve is opened, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com