Camellia fruit crushing equipment for grain and oil processing

A camellia fruit and crushing technology, which is applied in the fields of shelling, application, and oil/fat production, can solve the problems of increased labor intensity and low efficiency, and achieve the effects of ensuring the effect of crushing shells, improving work efficiency, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

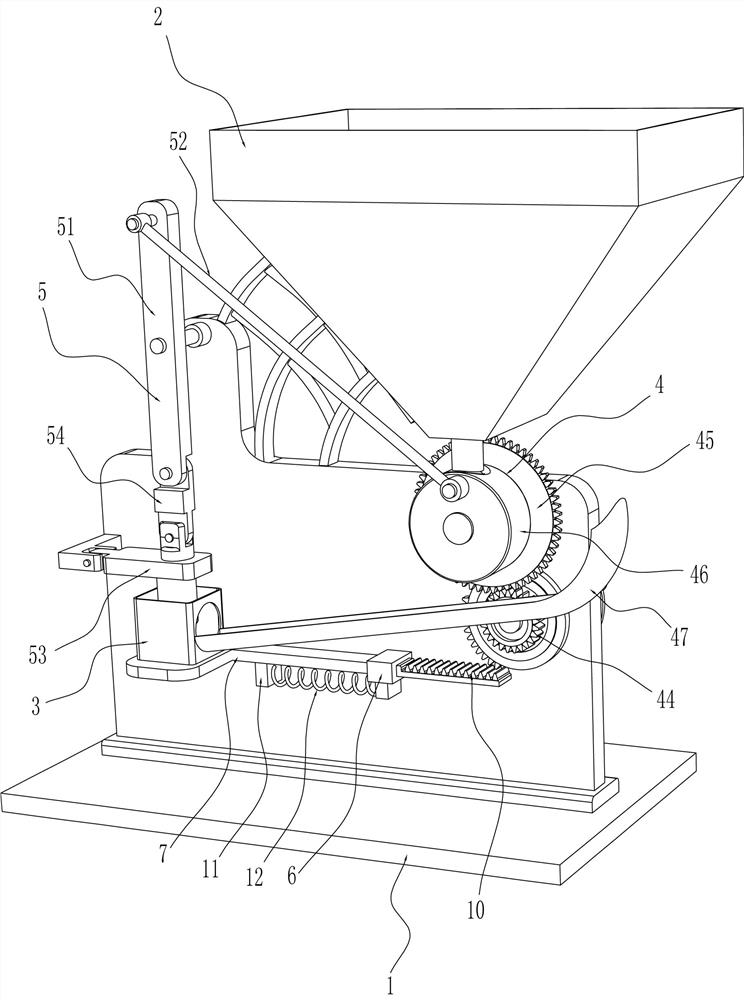

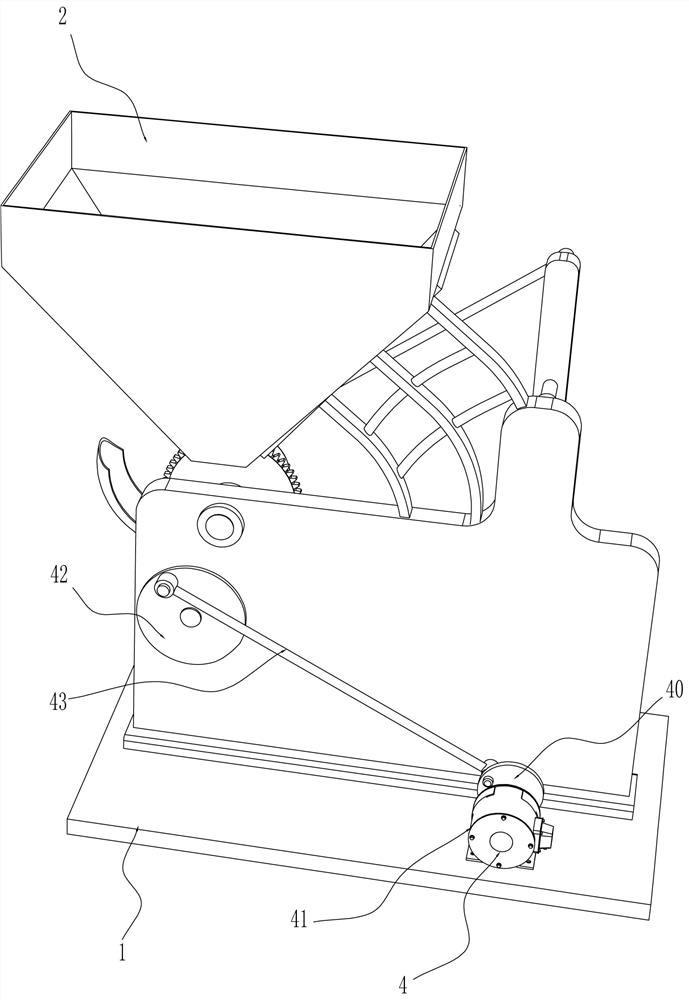

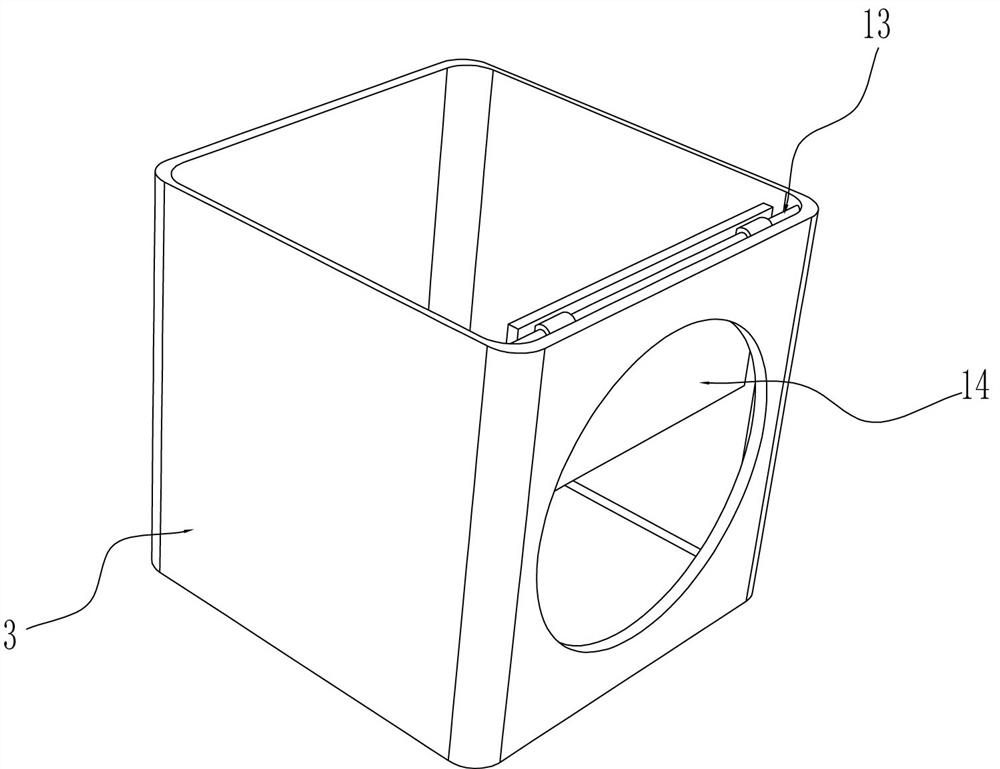

[0021] A kind of camellia fruit crushing equipment for grain and oil processing, such as Figure 1-4 As shown, it includes a frame 1, a silo 2 and a crushing frame 3. The top of the frame 1 is provided with a silo 2, and the left part of the front side of the frame 1 is fixedly connected with a crushing frame 3. The crushing frame 3 is connected to the machine by bolts. The frame 1 is connected to each other, and also includes a blanking mechanism 4, a crushing mechanism 5, a guide sleeve 6 and a supporting plate 7. The front right part of the frame 1 is provided with a blanking mechanism 4, and the crushing frame 3 is close to a part of the blanking mechanism 4. There is a feed port on the side, and the shape of the feed port is circular. The frame 1 above the crushing frame 3 is provided with a crushing mechanism 5. The front middle part of the frame 1 is fixed with a guide sleeve 6, which slides inside the guide sleeve 6. Supporting plate 7 is provided in a conventional man...

Embodiment 2

[0026] On the basis of Example 1, such as figure 1 and Figure 4 As shown, a discharge assembly is also included, and the discharge assembly includes a one-way clutch 8, a toothless gear 9, a rack 10, a fixed block 11 and a spring 12, which are used to connect the middle part of the rotating shaft of the pinion 44 and the large disc 42 A one-way clutch 8 is installed, and a missing tooth gear 9 is installed on the outside of the one-way clutch 8. A rack 10 is affixed to the tail end of the supporting plate 7, and the rack 10 is connected to the supporting plate 7 by a bolt connection. 10 is intermittently meshed with the tooth-missing gear 9, the bottom of the supporting plate 7 is connected with a fixed block 11, the fixed block 11 is connected with the supporting plate 7 by welding, and a spring 12 is connected between the fixed block 11 and the guide sleeve 6.

[0027] When the pinion 44 rotates counterclockwise, the one-way clutch 8 coaxially connected with it also rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com