Ceramic coating and preparation method thereof and method for preventing cracking of ceramic coating

A technology for ceramic coatings and pigments, applied in coatings and other directions, can solve the problems of high cost, long drying cycle, cracking, etc., and achieve the effect of not increasing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] In a second aspect of the present invention, a method for preparing a ceramic coating is provided, the method comprising:

[0079] Mix the above components A and B in a weight ratio of 2-3:1-2, stir and mature at room temperature for 3 hours or longer, so that the alkoxysilane in component B is hydrolyzed and mixed with The metal oxide sol in component A undergoes polycondensation reaction or itself undergoes polycondensation reaction to form a sol-gel ceramic coating.

[0080] In a third aspect of the present invention, there is provided a method for increasing the cracking film thickness of a ceramic coating, the ceramic coating is prepared based on a sol-gel method, the method comprising:

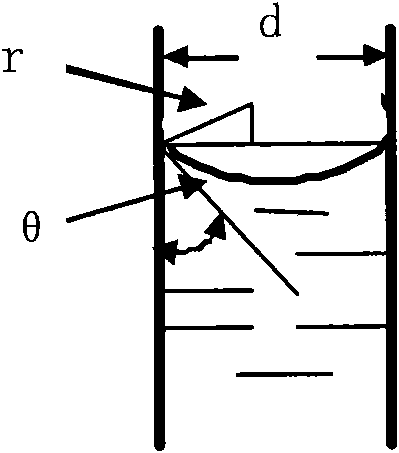

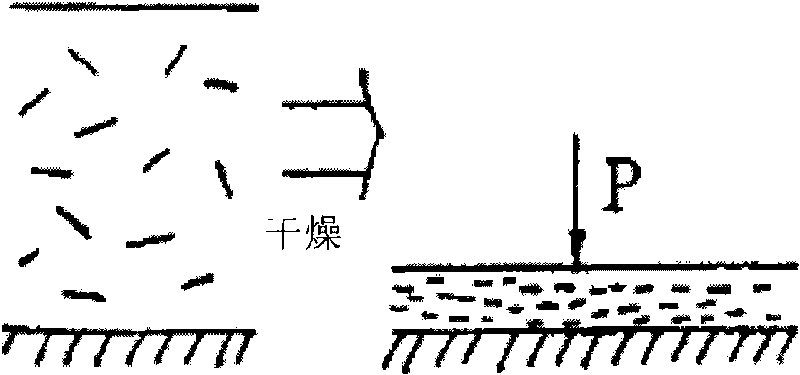

[0081] The above ceramic coating is sprayed onto the surface of the metal substrate treated by sandblasting to form a coating, and cured at 160-180° C. for 20 minutes to form a thick-film (40-50 μm) ceramic coating.

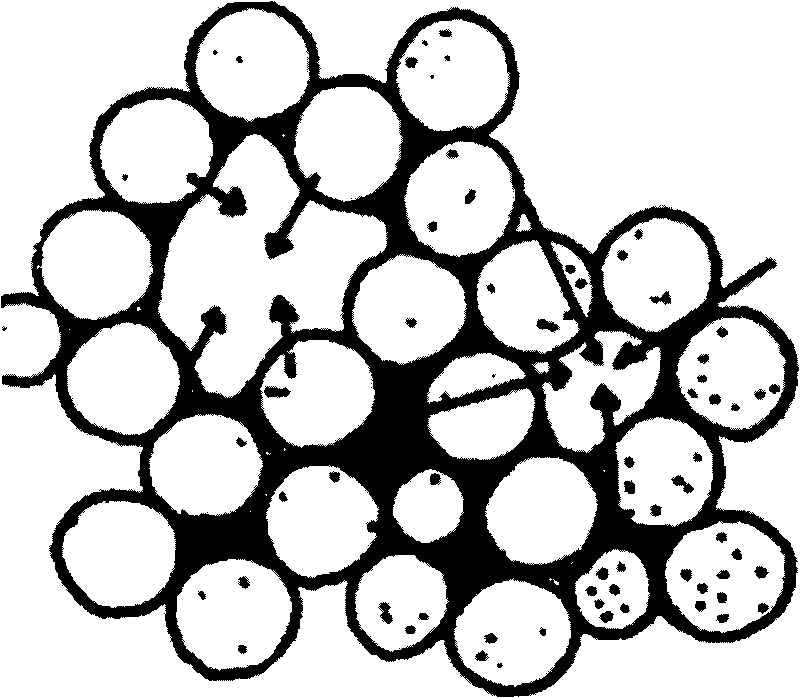

[0082] Refer to the accompanying drawings below.

[0083] i...

Embodiment 1-4

[0096] Using the same paint mixing and construction method as in Comparative Example 1, the difference is that part of the flaky aluminum hydroxide is used to replace the titanium dioxide in the formula, so that the sum of the two weights is 35 parts by weight.

[0097] Table 1

[0098]

Embodiment 5-10

[0100] The preparation, aging and construction methods of the paint are the same as in Comparative Example 1, except that the flake pigments are replaced by sericite powders of different particle sizes. The sheet diameter ratio is in the range of 6-150. The specific proportioning and test results are shown in Table 2 below.

[0101] Table 2

[0102]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com