Method for improving the selectivity and reaction stability of arene prepared in methanol aromatization manner

An aromatization and selective technology, which is used in the production of hydrocarbons from oxygen-containing organic compounds, organic chemistry, and bulk chemical production, etc., can solve the problem of catalyst stability, unresolved industrial production, and insufficient aromatics selectivity. problem, to achieve the effects of good reaction stability, inhibition of inactivation, and increased BTX yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

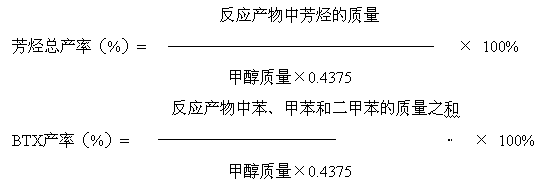

Image

Examples

Embodiment 1

[0026] Embodiment 1: firstly load an appropriate amount of glass beads at the bottom of the reaction tube bed of a miniature fixed-bed catalytic reactor with an internal diameter of 1.5 cm, spread a thin layer of quartz wool on the glass beads, and then add 3.0 to 5.0 g of cylindrical HZSM The -5 molecular sieve catalyst is loaded into the reaction tube, and the upper layer is filled with an appropriate amount of glass beads, and then the nitrogen flow rate is adjusted to nitrogen / methanol = 2.0 (mol / mol) to ensure that the gas flow evenly flows through the catalyst bed and keep the pressure of the reaction medium at 3.0MPa; Program temperature rise to 500°C in 100 minutes, cool down to 450°C after activation for 1 hour, and feed methanol with a metering pump to keep the mass space velocity of methanol at WHSV=2.5h -1 , the reaction effluent took the upper layer of organic matter as a product sample, after weighing and gas chromatography analysis, the total yield of aromatics a...

Embodiment 2

[0027] Embodiment 2: earlier the reaction tube bed bottom of the miniature fixed-bed catalytic reactor of internal diameter 1.5cm is loaded with an appropriate amount of glass beads, spreads a thin layer of quartz wool on the glass beads, and then 3.0 ~ 5.0g cylindrical Mn The modified HZSM-5 molecular sieve is loaded into the reaction tube as a catalyst, and an appropriate amount of glass beads is filled in the upper layer, and then the flow rate of carbon dioxide is adjusted to carbon dioxide / methanol = 2.0 (mol / mol) to ensure that the gas flow flows evenly through the catalyst bed and maintain the pressure of the reaction medium It is 3.0MPa; after 100 minutes, the temperature is programmed to rise to 500°C, after activation for 1h, the temperature is lowered to 450°C, and methanol is introduced with a metering pump to keep the methanol mass space velocity at WHSV=2.5h -1 , the reaction effluent took the upper layer of organic matter as a product sample, after weighing and g...

Embodiment 3

[0028] Example 3: The difference between this example and Example 2 is that Zr-modified HZSM-5 molecular sieve is used as a catalyst, carbon dioxide / methanol is kept at 0.6 (mol / mol), and other reaction conditions are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com