Composite conductive agent and dispersion method thereof as well as positive plate and lithium ion battery

A composite conductive agent and conductive agent technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unsatisfactory conductive effects, achieve excellent safety performance, increase rate performance, and improve liquid absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

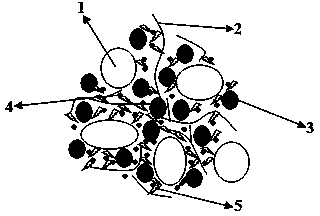

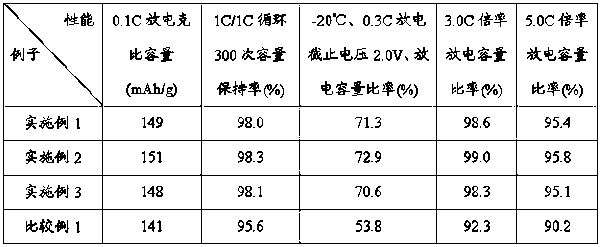

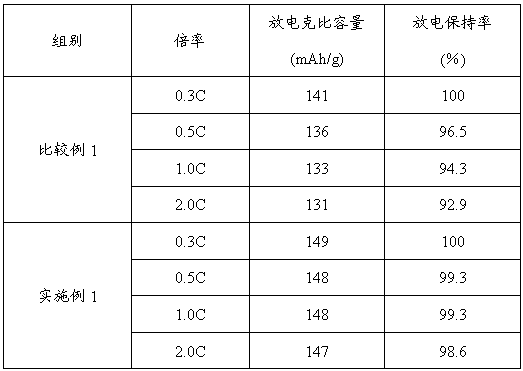

[0058] The composite conductive agent used in this example is composed of carbon black with D50 at 20-60nm, submicron graphite particle conductive agent with D50 at 600nm, spherical conductive graphite KS-6 with D50 at 5 μm, and carbon nanotubes with 500nm-5 μm , and the percentages by weight of the composite conductive agent are: 40%, 15%, 15%, and 30%, respectively.

[0059] The composite conductive agent is effectively dispersed by nanometer ultra-fine dispersion technology in the preparation process of the positive electrode slurry. Specifically, it refers to the introduction of the polymer dispersant polyvinylpyrrolidone in the dispersion process of the composite conductive agent, and the high-viscosity dispersion mixer is used for high-speed dispersion. , and then under the strong mechanical shear force of the ultra-fine dispersion equipment, the aggregates such as fine powder clusters in the solution are further dispersed to obtain sufficiently fine powder particles, whi...

Embodiment 2

[0064] The nano-submicron three-dimensional network composite conductive agent used in this embodiment consists of acetylene black with D50 at 20-60nm, submicron graphite particle conductive agent with D50 at 400nm, spherical conductive graphite KS-6 with D50 at 3 μm and 500nm-6 μm The carbon nanofibers are composed of carbon nanofibers, and their weight percentages in the composite conductive agent are respectively: 30%, 20%, 20%, and 30%.

[0065] The formula and preparation method of the positive electrode slurry are the same as in Example 1, except that the composite conductive agent of this example is used as the conductive agent; the negative electrode sheet, separator, electrolyte and packaging shell are the same as in Example 1.

Embodiment 3

[0067] The nano-submicron three-dimensional network composite conductive agent used in this example consists of Super-P with a D50 of 20-60nm, a submicron (or called flake nano) graphite particle conductive agent with a D50 of 900nm, and a spherical graphite particle with a D50 of 7μm. The conductive graphite KS-6 is composed of carbon nanofibers of 500nm-4μm, and their weight percentages in the composite conductive agent are respectively: 35%, 30%, 10%, and 25%.

[0068] The formula and preparation method of the positive electrode slurry are the same as in Example 1, except that the composite conductive agent of this example is used as the conductive agent; the negative electrode sheet, separator, electrolyte and packaging shell are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Gram capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com