Preparation method for embedded multi-orientation metal nanowire transparent conductive film

A transparent conductive film, metal nanowire technology, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc. The effect of transparency and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Hydroxylation of Temporary Substrate

[0035] In this case, the temporary substrate was treated with hydroxylation to enhance the hydrophilicity of the substrate surface, which is conducive to the uniform distribution of metal nanowires on the substrate surface and the formation of directional alignment. In addition, the hydroxyl group provides reaction sites for the subsequent grafting of anti-adhesive groups; the temporary substrate used can be a flexible substrate or a rigid substrate; the hydroxylation treatment used can be carried out by chemical solution surface grafting or ultraviolet ozone treatment, etc. . Provide two embodiments respectively below and illustrate:

[0036] If the temporary substrate used is flexible polyethylene terephthalate (PET). By pulling impregnation method, it was immersed in APTES-toluene mixed solution, the concentration of APTES was 5wt%, the immersion time was 10min, and then pulled out from APTES at a speed of 2000μm / s. ...

Embodiment 2

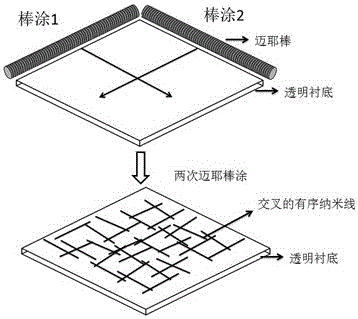

[0038] Embodiment 2 Preparation of double-oriented nano-silver wire transparent film

[0039] For one-dimensional metal nanowires, the micro-grain on the Meyer rod guides the nanowires during the rod coating process to realize the control of the orientation of the nanowires. After a single coating, the film is dried, and then the nanowires are sequentially coated for the next time, so that the double-oriented ordered metal nanowires can be obtained to form a uniform conductive network.

[0040] In this case, hydroxylated glass was used as a temporary substrate, and nano silver wires were used as metal nanowires to prepare multilayer ordered conductive films. The silver nanowires used have an average diameter of 34 nm and a length of 18 μm. The silver nanowires are dispersed in an ethanol solution with a concentration of 10 mg / ml. The silver nano wire dispersion liquid and anhydrous isopropanol were mixed according to the mass ratio of 1:4, and shaken to disperse evenly after ul...

Embodiment 3

[0043] Embodiment 3 selective hydrophilic treatment

[0044] The key step of the invention is to selectively modify the nano silver wire-temporary substrate, that is, only carry out hydrophobic modification on the modified substrate, without modifying the nano silver wire itself.

[0045] Preference is given to hexamethyldisilane as the modifying material. Draw 2 ml of hexamethyldisilane solution, drop it into a Petri dish, and place it in a closed oven with the temperature set at 70 °C; place the above-mentioned ordered silver nanowires-hydroxylated glass above the solution.

[0046] During the evaporation of the solution, the imino groups of the hexamethyldisilane solution react with the hydroxyl groups on the glass surface to generate trimethylsiloxy groups. For sufficient reaction, the deposition time was set at 20 minutes. Pure silver nanowires do not have hydroxyl groups, so they will not bond with silane, and their surface will not be hydrophobized. The purpose of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com