Graphene-based water-based conductive ink prepared by one-step method and preparation method thereof

A conductive ink, alkene-based water-based technology, applied in inks, household appliances, applications, etc., can solve the problems of high production cost, complex process, long time consumption, etc., and achieve the effect of saving consumables, simple preparation method, and improved conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

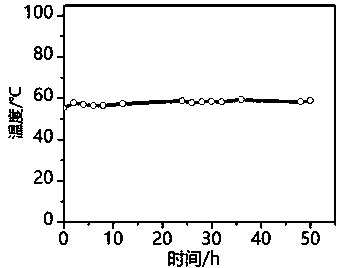

Image

Examples

Embodiment 1

[0023] A preparation method of modified graphene-based water-based conductive ink, comprising weighing 80 parts of saturated bromine solution, 5 parts of expanded graphite, 4 parts of defoaming agent, 1 part of leveling agent, 1 part of thickener, adhesion promoting Add 1 part of agent, 20 parts of superconducting carbon black, and 25 parts of resin into a high-pressure homogenizer for high-pressure shearing and grinding to obtain graphene-based water-based conductive ink.

Embodiment 2

[0025] Weigh 80 parts of saturated bromine solution, 5 parts of expanded graphite, 6 parts of defoamer, 3 parts of leveling agent, 1.5 parts of thickener, 1 part of adhesion promoter, 10 parts of superconducting carbon black, fumed silica 10 parts and 30 parts of resin are added to a high-pressure homogenizer for high-pressure shearing and grinding to obtain graphene-based water-based conductive ink.

Embodiment 3

[0027] Weigh 80 parts of saturated iodine solution, 6 parts of expanded graphite, 3 parts of defoamer, 1 part of leveling agent, 2 parts of thickener, 1 part of adhesion promoter, 10 parts of superconducting carbon black, liquid phase carbon dioxide Add 10 parts of silicon and 30 parts of resin into a high-pressure homogenizer for high-pressure shearing and grinding to obtain graphene-based water-based conductive ink 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com