Method for preparing graphene wrapped 3D flowerlike nickel sulfide/foamed nickel material

A technology of graphene coating and nickel foam, which is applied in the field of lithium-ion batteries, can solve problems such as the loss of sulfur element extraction, the reduction of lithium storage performance of materials, the attenuation of battery cycle performance and rate performance, and achieve the improvement of electrical conductivity and electrical conductivity. , Improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0025] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

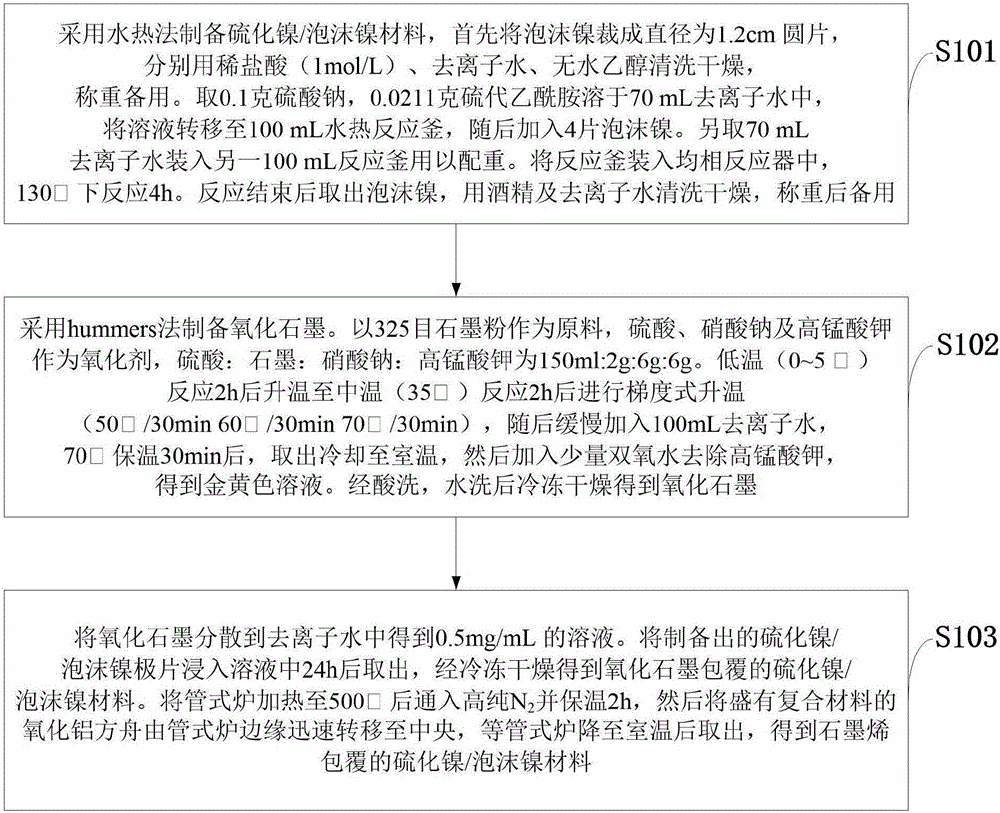

[0026] Such as figure 1 As shown, the preparation method of the graphene-coated 3D flower-shaped nickel sulfide / nickel foam material provided by the embodiments of the present invention comprises the following steps:

[0027] S101: Prepare nickel sulfide / nickel foam material by hydrothermal method. First, cut nickel foam into discs with a diameter of 1.2 cm, wash and dry with dilute hydrochloric acid (1mol / L), deionized water, and absolute ethanol respectively, and weigh them for lat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com