Composite nanotube composed of molybdenum disulfide-carbon-carbon nanotube and preparation method thereof

A carbon nanotube, molybdenum disulfide technology, applied in the direction of molybdenum sulfide, chemical instruments and methods, carbon compounds, etc., can solve the problems of poor electrical conductivity, low catalysis, uneven load, etc., to improve electrical conductivity, The effect of improving dispersibility and reducing impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

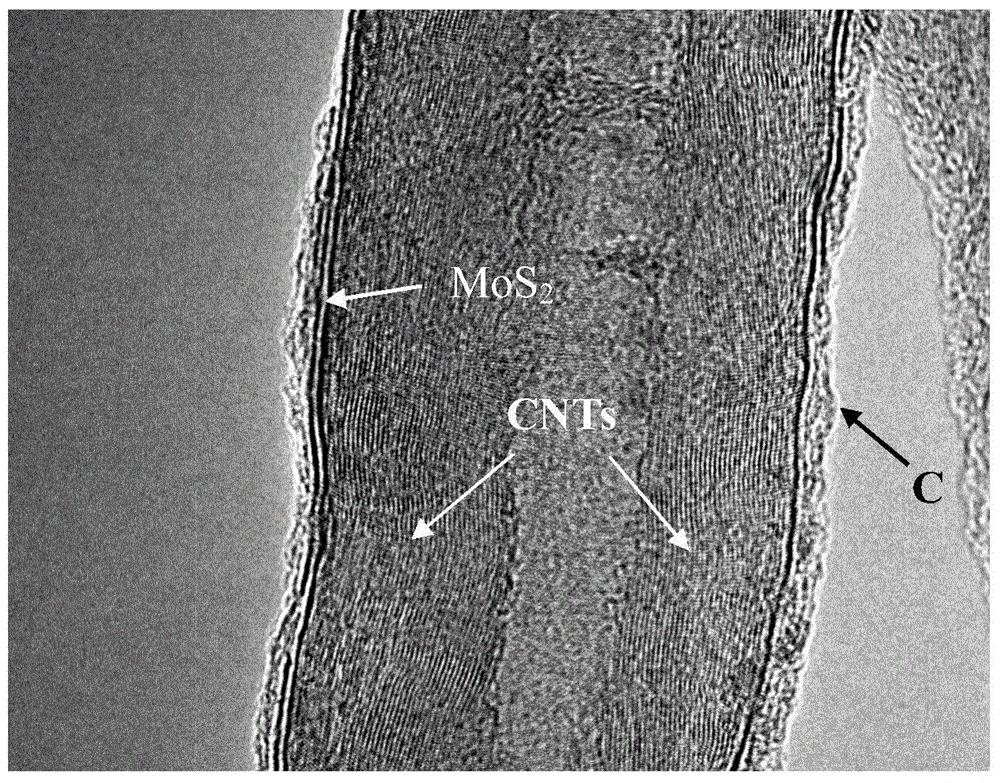

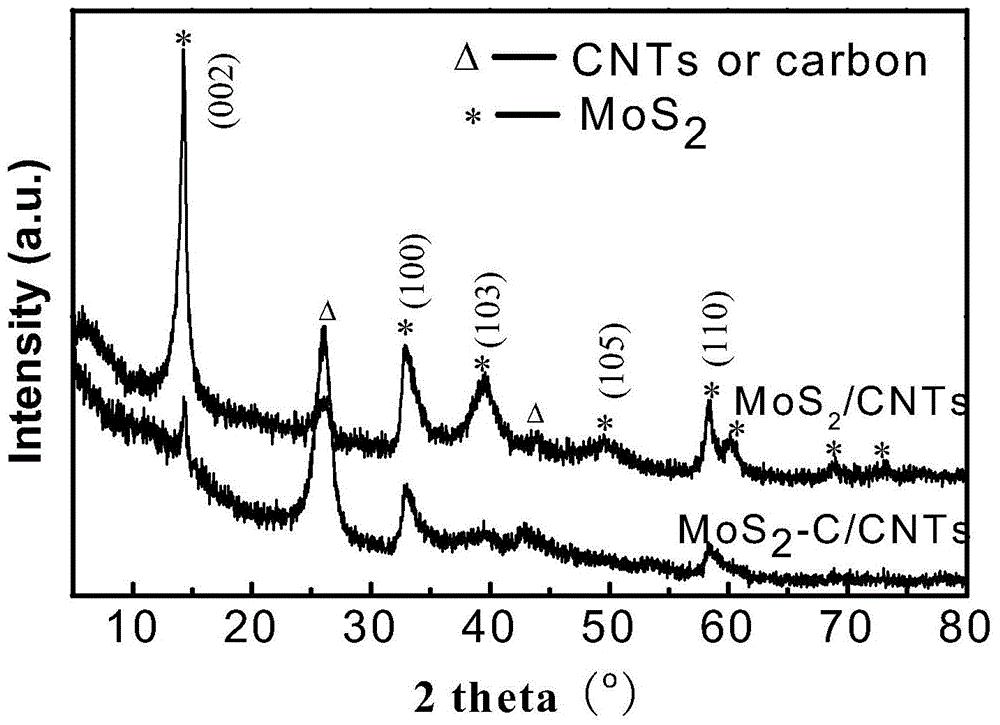

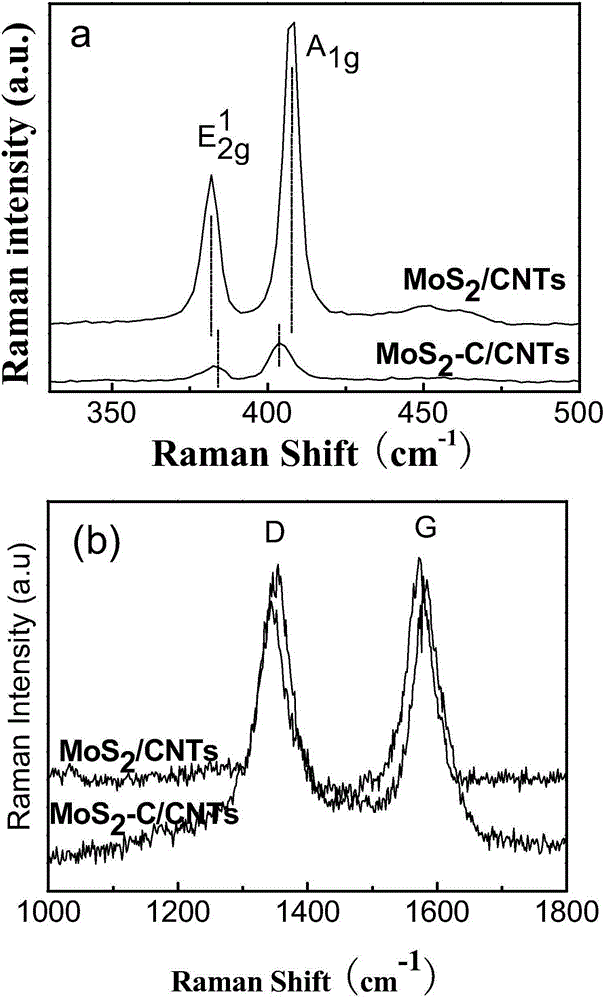

Embodiment 1

[0037]Dissolve 5g of ammonium molybdate in distilled water, add 40ml of ammonium sulfide solution and 20ml of ammonia water with a mass concentration of 28-29%, and react at 60-70°C for 2 hours. After the reaction, stand and crystallize at 2-10°C for 48 hours. Filter and dry at room temperature to obtain ammonium tetrathiomolybdate crystals; dissolve 2g of ammonium tetrathiomolybdate crystals and 0.4g of polyvinyl alcohol (number average molecular weight 1000) in 50ml of water to obtain a mixed solution, and then add 0.5g of multi-wall Carbon nanotubes were ultrasonically dispersed for 4 hours and then centrifuged, washed with distilled water and absolute ethanol in turn, dried at 60°C, then calcined at 850°C for 2 hours under the protection of hydrogen, and cooled to room temperature to obtain MoS 2 -C / CNTs composite nanotubes. MoS on carbon nanotubes 2 and the loading of amorphous carbon accounted for the mass percentage of composite nanotubes were: 18% and 1.5%.

Embodiment 2

[0039] Dissolve 5g of ammonium molybdate in distilled water, add 40ml of ammonium sulfide solution and 20ml of ammonia water with a mass concentration of 28-29%, and react at 60-70°C for 2 hours. After the reaction, stand and crystallize at 2-10°C for 48 hours. Filter and dry at room temperature to obtain ammonium tetrathiomolybdate crystals; dissolve the 1.5g ammonium tetrathiomolybdate crystals and 0.8g polyvinyl alcohol (number average molecular weight 1200) in 50ml of water in sequence to obtain a mixed solution, and then add 0.5 g multi-walled carbon nanotubes, ultrasonically dispersed for 4 hours and then centrifuged, washed with distilled water and absolute ethanol in turn and dried at 60°C, then calcined at 800°C for 2 hours under the protection of hydrogen, and cooled to room temperature to obtain MoS 2 -C / CNTs composite nanotubes. MoS on carbon nanotubes 2 and the loading amount of amorphous carbon accounted for the mass percentage of the composite system were: 15% ...

Embodiment 3

[0041] Dissolve 5g of ammonium molybdate in distilled water, add 40ml of ammonium sulfide solution and 20ml of ammonia water with a mass concentration of 28-29%, and react at 60-70°C for 2 hours. After the reaction, stand and crystallize at 2-10°C for 48 hours. Filter and dry at room temperature to obtain ammonium tetrathiomolybdate crystals; the following: 2.5g ammonium tetrathiomolybdate crystals and 0.6g polyvinyl alcohol (number average molecular weight 800) were dissolved in 50ml water successively to obtain a mixed solution, and then added 0.5g of multi-walled carbon nanotubes, ultrasonically dispersed for 4 hours and then centrifuged, washed with distilled water and absolute ethanol in turn and dried at 60°C, then calcined at 800°C for 2 hours under the protection of hydrogen, cooled to room temperature to obtain MoS 2 -C / CNTs composite nanotubes. MoS on carbon nanotubes 2 and the loading amount of amorphous carbon accounted for 20% and 2.1% of the mass percentage of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com