Compound capable of being used for thermoelectric material and preparation method thereof

A technology of thermoelectric materials and compounds, applied in the direction of thermoelectric device junction lead wire materials, etc., can solve the problems of low thermoelectric conversion efficiency, and achieve the effects of superior thermoelectric performance, improved mobility, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Adopt Cu powder, Zn powder, Sn powder and S powder (mass percentage purity is respectively 99.7%, 99.99%, 99.9% and 99.999% the same below) according to Cu 2 ZnSnS 4 and Cu-doped sample Cu 2+x Zn 1-x SnS 4 (x = 0 ~ 0.10) chemical formula weighed and put into a glass tube, vacuum (less than 10 -2 Pa) and sealed with a hydrogen-oxygen flame, the glass tube containing the mixture was slowly heated to 450°C and kept for 24 hours, and then heated to 600°C-700°C for the first solid phase reaction, the reaction time was 24-96h. After the tube is opened, the powder is ground and repackaged for the second solid phase reaction. The conditions and reaction conditions are the same as the first solid phase reaction. The pure-phase powder obtained is subjected to SPS sintering at 650°C-800°C under a pressure of 40-60 MPa, and finally made into a bulk material for thermoelectric testing.

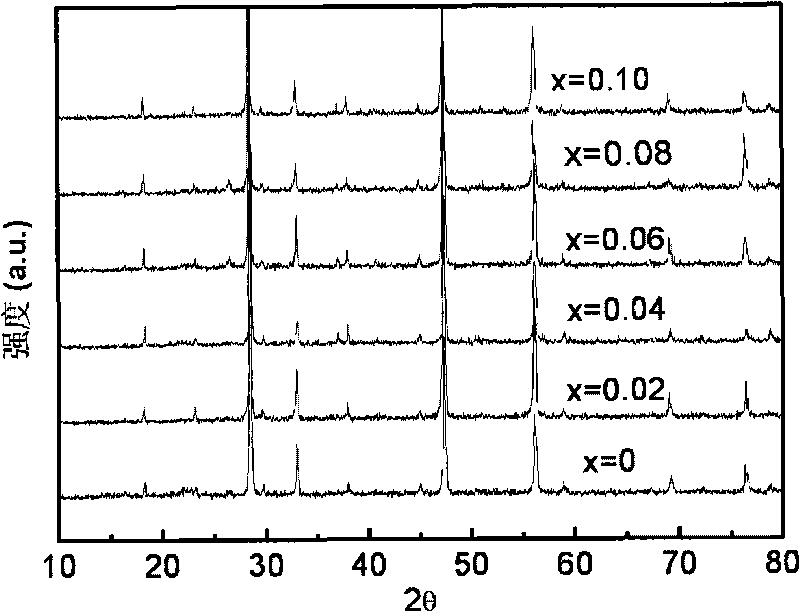

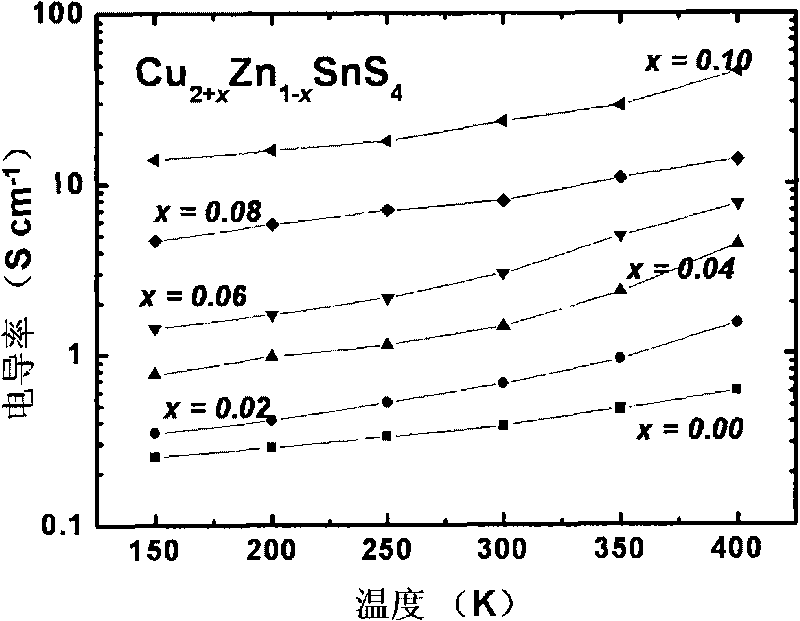

[0041] Polycrystalline XRD diffraction pattern ( figure 2 ) indicates that a pure-phase p...

Embodiment 2

[0043] Adopt Cu powder, Zn powder, Sn powder and S powder (purities are 99.7%, 99.99%, 99.9% and 99.999% respectively) according to Cu 2 ZnSnS 4 and Cu-doped sample Cu 2+x Zn 1-x sn S 4 (x = 0 ~ 0.10) chemical formula weighed and put into a glass tube, vacuum (less than 10 -2 Pa) and then sealed with a hydrogen-oxygen flame, melting reaction at 700-1000°C, and SPS sintering of the obtained pure-phase powder at 650-800°C with a pressure of 40-60MPa, and finally made into a thermoelectric test bulk material.

[0044] The polycrystalline XRD diffraction pattern is similar to Example 1, indicating that we have obtained a pure-phase polycrystalline sample. The electrical conductivity of the material is similar to that of Example 1, and the Seebeck coefficient, thermal conductivity at room temperature, and thermoelectric figure of merit at room temperature are all comparable to those of Example 1.

Embodiment 3

[0046] Adopt Cu powder, Zn powder, Sn powder and S powder (purities are 99.7%, 99.99%, 99.9% and 99.999% respectively) according to Cu 2 ZnSnS 4 and Cu-doped sample Cu 2+x Zn 1-x SnS 4 Weigh the chemical formula (x=0~0.10) and put it into a high-energy ball mill jar, fill it with argon, seal it, and mill it for 5 hours. SPS sintering was carried out under pressure to finally make the bulk material for thermoelectric testing.

[0047] The polycrystalline XRD diffraction pattern is similar to Example 1, indicating that we have obtained a pure-phase polycrystalline sample. The electrical conductivity of the material is similar to that of Example 1, and the Seebeck coefficient, thermal conductivity at room temperature, and thermoelectric figure of merit at room temperature are all comparable to those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com