Lithium-supplementing additive as well as preparation method and application thereof

An additive and lithium-replenishing technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of low utilization rate, by-products or gas generation, etc., to improve utilization rate, improve electrical conductivity, and improve battery capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

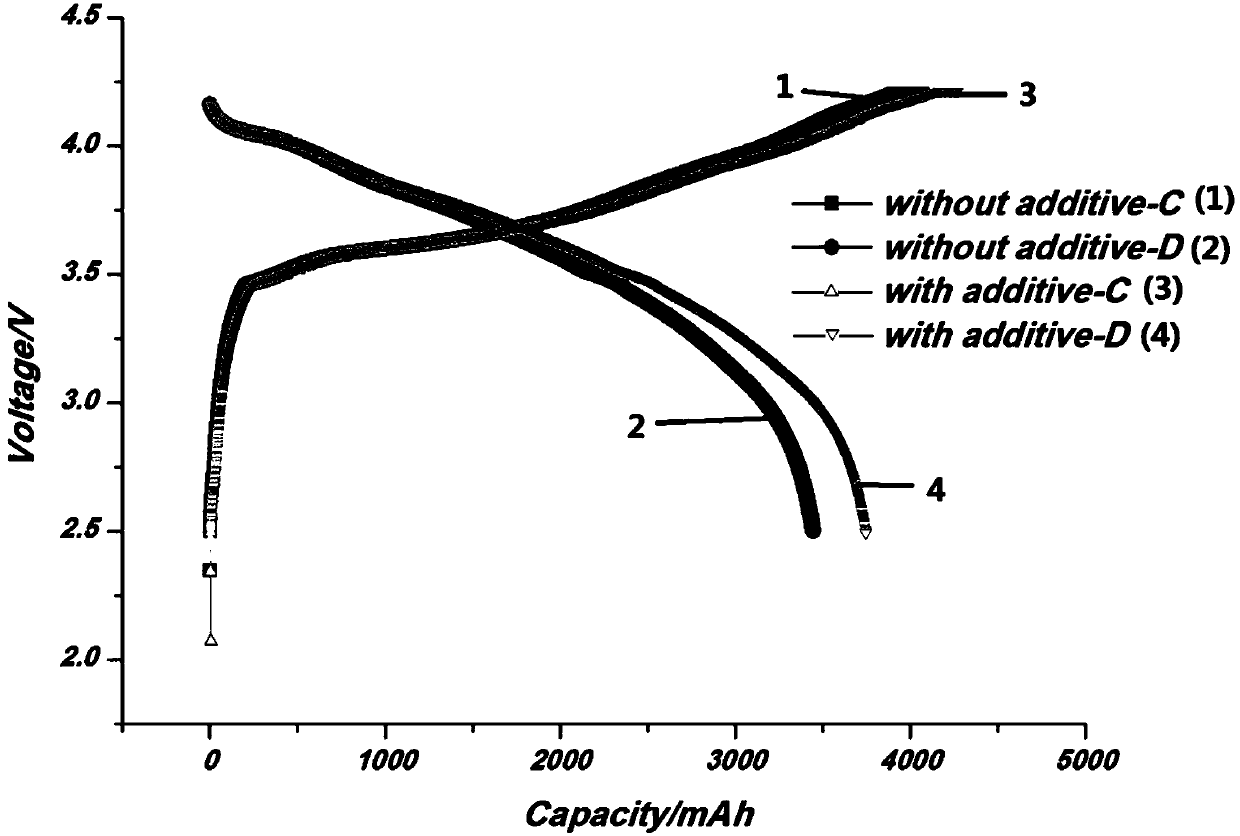

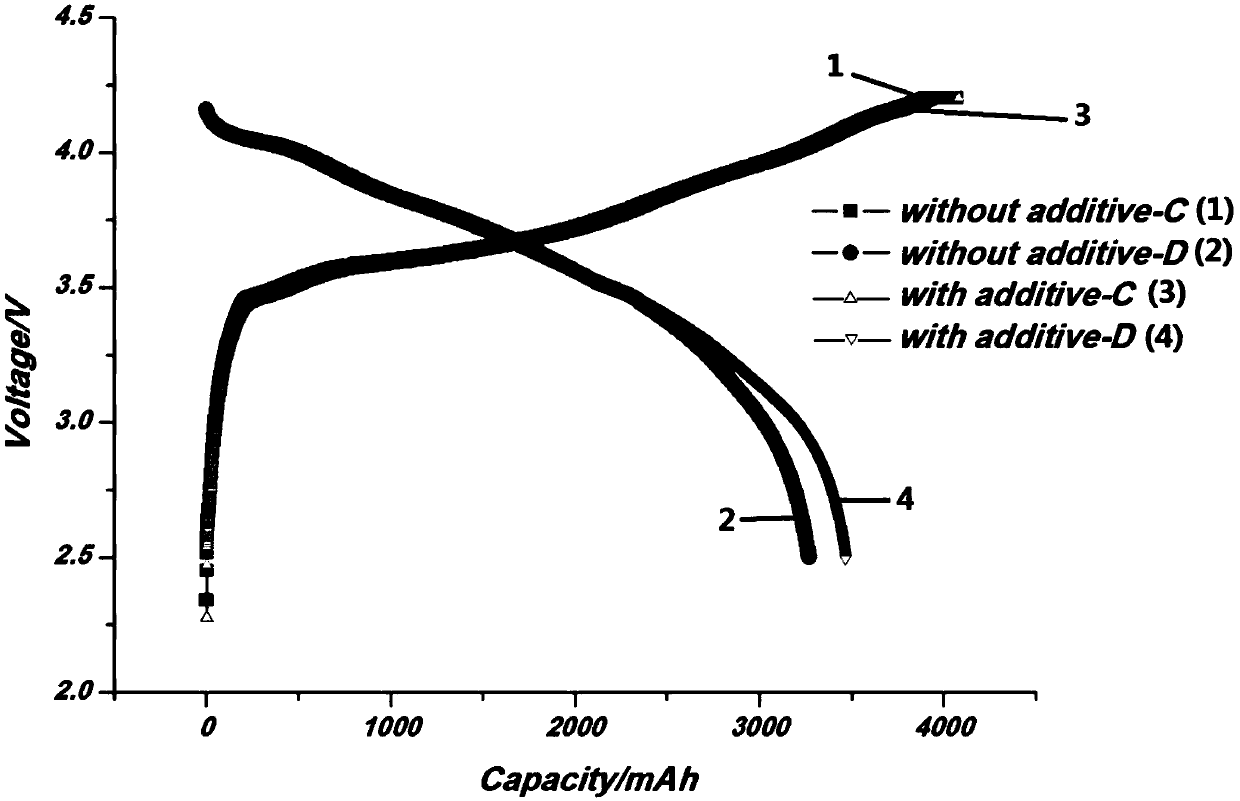

[0047] In this example, three lithium sources of lithium hydroxide, lithium carbonate and lithium peroxide were used to prepare lithium supplement additives. The lithium supplement additive is added to the positive electrode material and the negative electrode material respectively, and used as the positive electrode lithium supplement additive and the negative electrode lithium supplement additive respectively. The effects of adding lithium-supplementing additives and not adding lithium-supplementing additives on the first charge and discharge of the battery were tested respectively. details as follows:

[0048] Lithium supplement additive preparation method one:

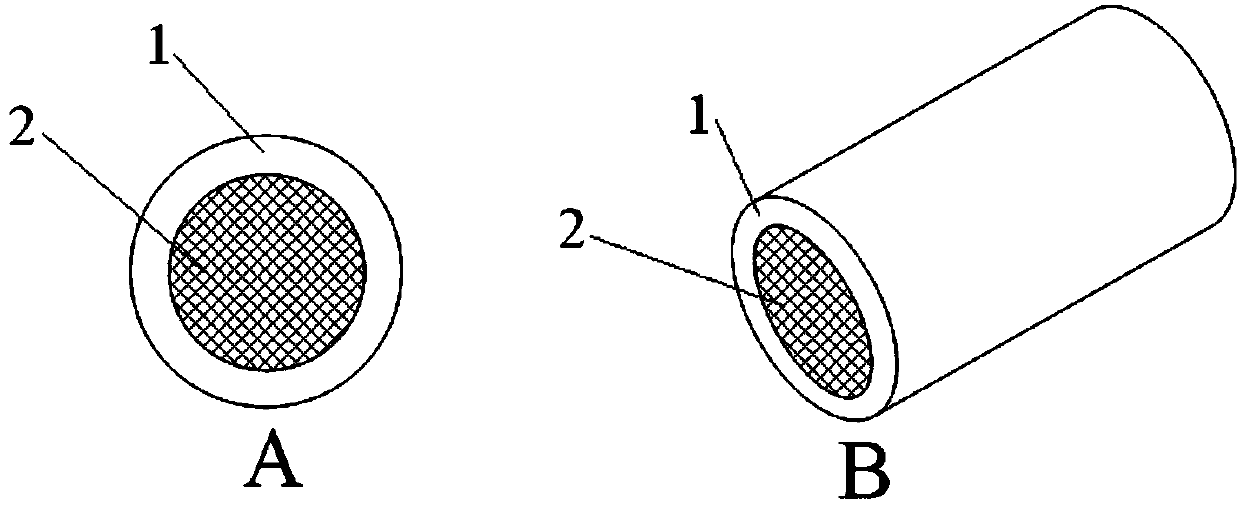

[0049] (1) Vacuum dry the carbon nanospheres and mix them with anhydrous lithium hydroxide evenly. The quality of the carbon nanospheres and lithium hydroxide is 30g and 70g respectively to make a mixture; the mixing method can be grinding, ball milling or Dry stirring method, this example specifically adopts bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com