Copper-clad aluminum conductor

A copper-clad aluminum and wire technology, which is applied in the direction of metal/alloy conductors, carbon-silicon compound conductors, cable/conductor manufacturing, etc., can solve the problems of unfavorable light weight of wires, etc., and achieve the effect of wide application and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

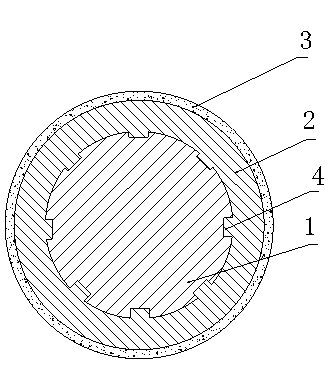

[0021] Such as figure 1 As shown, a copper-clad aluminum wire includes an aluminum core 1, a copper cladding layer 2 is provided on the outside of the aluminum core 1, and a graphene film layer 3 is provided on the outside of the copper cladding layer 2.

[0022] The cross section of the aluminum core 1 is circular.

[0023] The material of the copper cladding layer 2 is refined copper with a purity of 99.97% or more.

[0024] Concave-convex ribs 4 are provided on the bonding surface of the aluminum core 1 and the copper cladding layer 2 .

[0025] The graphene film layer 3 is formed by chemical vapor deposition.

Embodiment 2

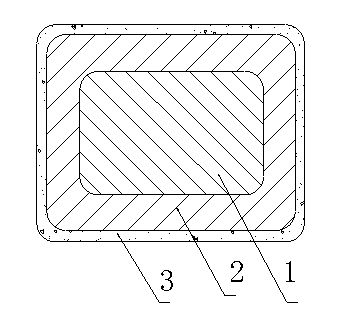

[0027] The difference between this embodiment and Embodiment 1 is that the section of the aluminum core is rectangular.

[0028] The use of the copper-clad aluminum wire of the present invention is not only beneficial to the transmission of high-frequency signals, but also very beneficial to the transmission of DC or low-frequency high-power electricity. The use of the aluminum core increases the outer diameter of the wire while ensuring light weight, thereby The attachment area of the graphene film layer is increased, which is more conducive to the transmission of high-power electricity. Even if there is no skin effect, the aluminum core, copper cladding layer and graphene film layer can be regarded as three wires used in parallel to give full play to the high conductivity of graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com