Carbon-based material/polymer composite material and preparation method thereof

A carbon-based material and composite material technology, applied in chemical instruments and methods, synthetic resin layered products, rubber layered products, etc., can solve the problems of low carbon nanotube content, low electrical conductivity, and large carbon nanotube spacing. , to achieve a wide range of applicability, improve electrical conductivity, improve the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

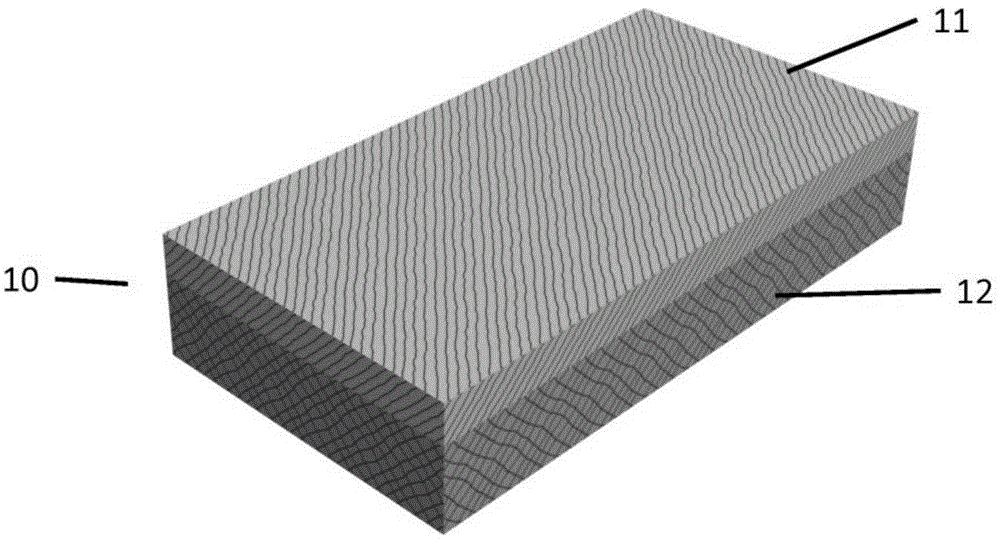

[0041] The preparation method of the carbon-based material / polymer composite material 10 comprises the following steps:

[0042] 1) Mix and disperse carbon-based materials in a solvent to prepare a uniformly dispersed mixed dispersion;

[0043] 2) Remove the solvent in the above mixed dispersion to form a film with an electrical and thermal network;

[0044] 3) In situ polymerizing a flexible polymer as a matrix in the above film;

[0045] 4) Remove the filter membrane on the surface of the material obtained in step 3) to obtain a carbon-based material / polymer composite material 10 with a flexible polymer layer 12 and a conductive layer.

[0046] Further, the solvent in the step 1) is ethanol, acetone or dimethylformamide.

[0047] The mixing and dispersion in the step 1) is realized by ultrasonic crushing or ultrasonic dispersion, and the method for removing the solvent in the mixed dispersion in the step 2) is a vacuum filtration method.

[0048] In the carbon-based mater...

Embodiment 1

[0056] The carbon-based material used in this embodiment is carbon nanotubes grown by chemical vapor deposition. The diameter of carbon nanotubes is 10-30nm, the length is >5um, and the purity is >=95%. Other reagents are analytical reagents purchased on the market. , no further processing is required.

[0057] The preparation method of the carbon-based material / polymer composite material 10 of this embodiment includes the following four steps:

[0058] 1) Preparation of multi-walled carbon nanotube dispersion: Disperse 150 mg of carbon nanotubes in 50 ml of ethanol, and use an ultrasonic cell disruptor at a power of 240 W to sonicate for 10 minutes, so that the multi-walled carbon nanotubes are evenly dispersed in ethanol, Prepare a uniformly dispersed mixed dispersion;

[0059] 2) Remove the solvent in the above mixed dispersion to make a film with a conductive and heat-conducting network. Specifically, use a suction filter funnel and a circulating water vacuum pump to prep...

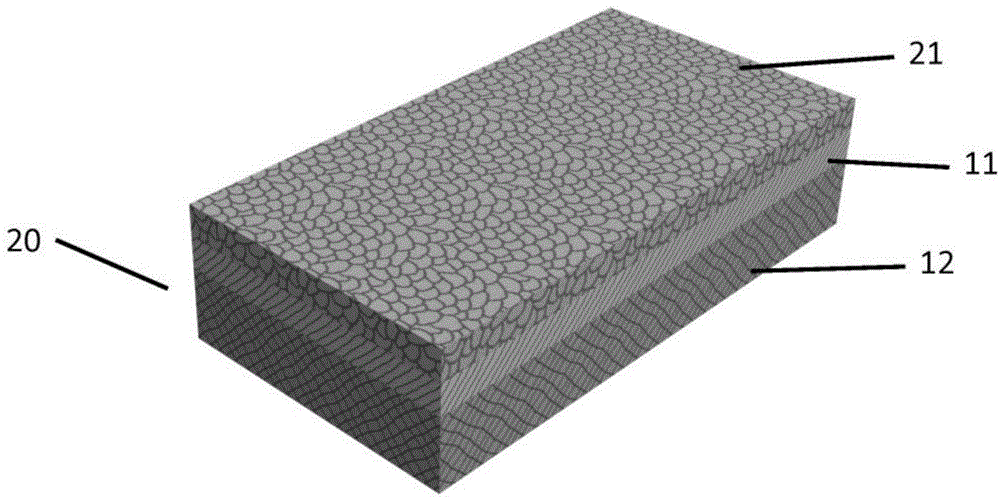

Embodiment 2

[0065] The carbon-based material used in this embodiment is a carbon nanotube grown by chemical vapor deposition. The diameter of the carbon nanotube is 10-30nm, the length is >5um, and the purity is >=95%; aniline and ammonium persulfate are purchased on the market Analytical grade reagents without further processing.

[0066] The carbon-based material / polymer composite material 10 of this embodiment also includes a layer of organic conductive polymer material layer 21, and the preparation method of the three-layer carbon-based material / polymer composite material 20 is divided into the following five steps:

[0067] 1) Preparation of multi-walled carbon nanotube dispersion liquid, disperse 150mg of carbon nanotubes in 50ml of ethanol, use an ultrasonic cell breaker at a power of 240W, ultrasonic treatment for 10min, so that the multi-walled carbon nanotubes are evenly dispersed in ethanol, Prepare a uniformly dispersed mixed dispersion;

[0068] 2) Remove the solvent in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com