Graphene-carbon black composite conductive coating, preparation method and application thereof

A technology of composite conductive and conductive coatings, applied in conductive coatings and other directions, can solve the problems of poor conductivity, high cost, low mechanical properties, etc., and achieve the effect of improving conductivity and increasing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

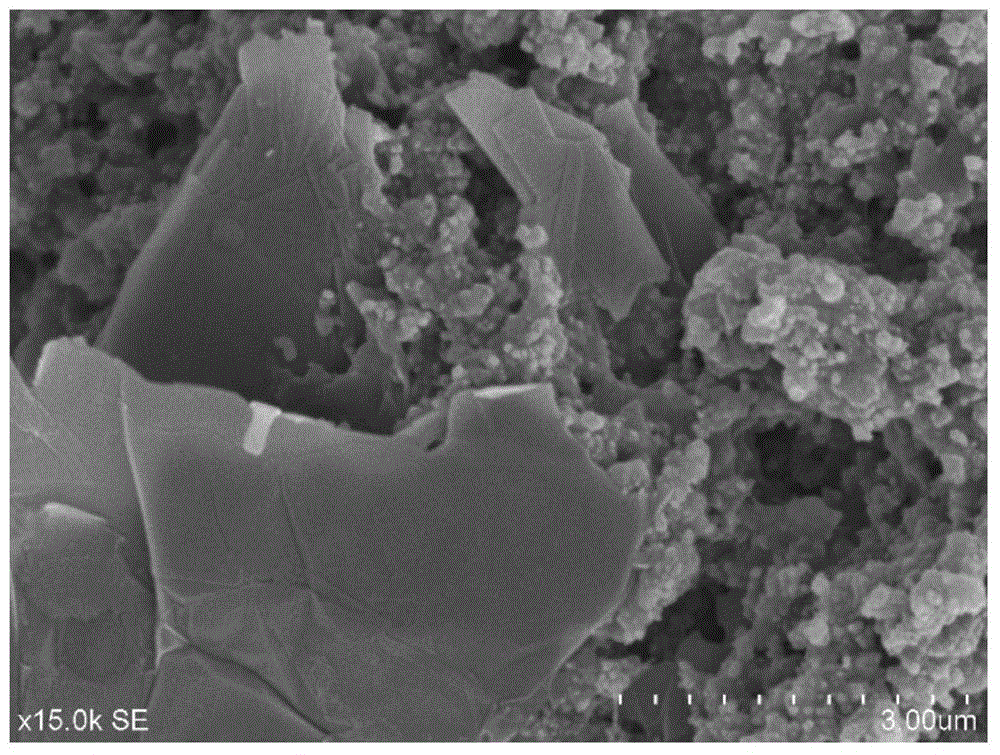

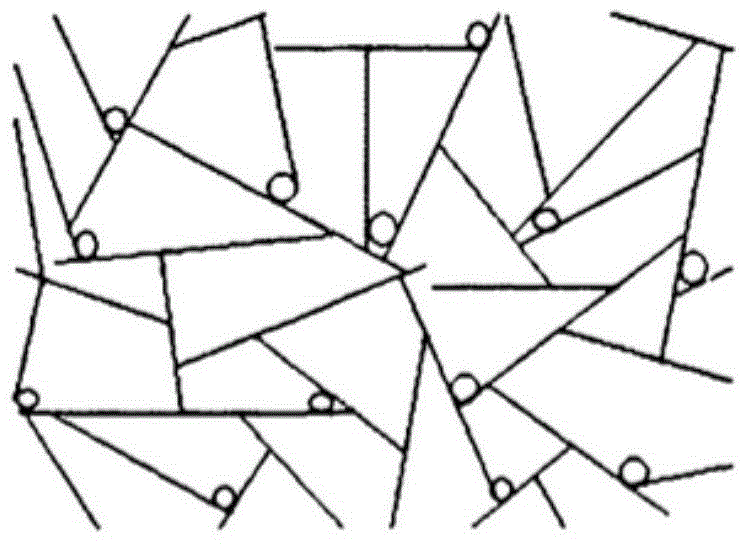

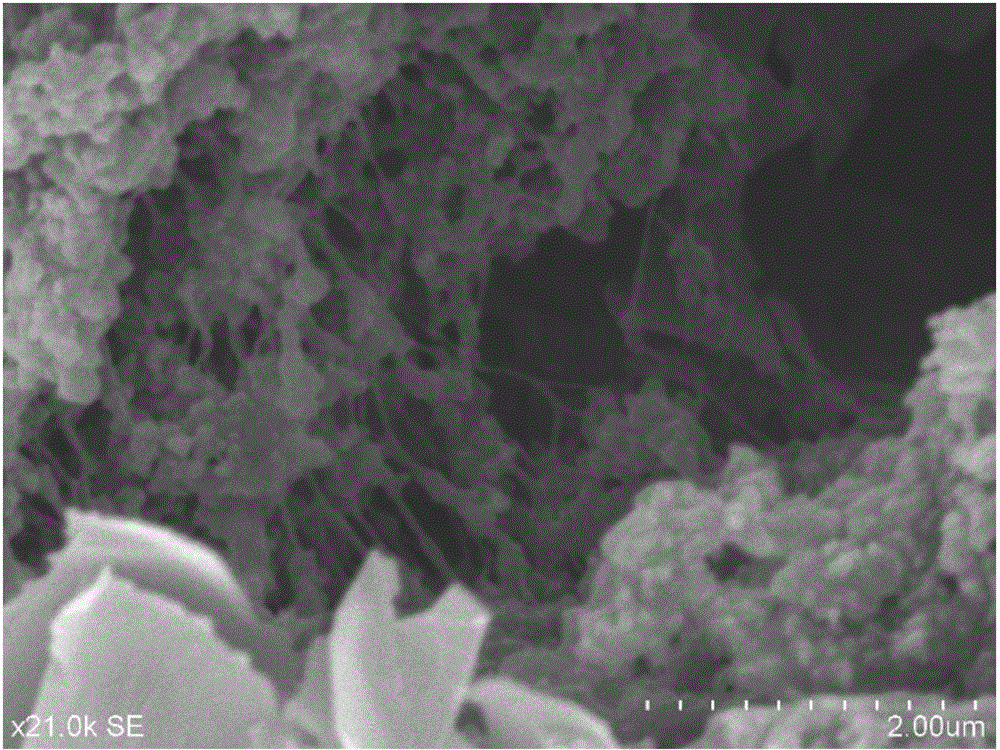

Image

Examples

preparation example Construction

[0044] The present invention also provides a kind of preparation method of graphene-carbon black composite conductive coating, and the method comprises the following steps:

[0045] (1) Stir and mix the ground matrix, water-based graphene and the second dispersant under the first stirring condition, then add carbon black and stir and mix under the second stirring condition;

[0046] (2) grinding the mixture obtained through step (1);

[0047] (3) Add the first water-based resin and the first dispersant to the graphene-carbon black dispersion obtained after grinding in step (2) and stir under the third stirring condition.

[0048] According to the present invention, in step (1), the first stirring conditions include: the stirring rate can be 500-1000rpm, preferably 700-1000rpm, and the stirring time can be 30-60min, preferably 40-60min; The second stirring conditions include: the stirring rate may be 1000-1500 rpm, preferably 1200-1500 rpm, and the stirring time may be 1.5-2.5...

Embodiment 1

[0064] This embodiment is used for illustrating and adopting the method of the present invention to prepare graphene-carbon black composite conductive paint

[0065] (1) Add 300g water, 18g polycarboxylate ammonium salt dispersant SN-5027, 6g dispersant 760W and 450g water-based graphene into the stirring tank, stir at room temperature for 40min at 700r / min, then add 120g Conductive carbon black, stirred at 1200r / min for 2h;

[0066] (2) The mixture of step (1) is then put into a grinder, ground to a fineness of 0.2 μm, and discharged to obtain a graphene / carbon black dispersion;

[0067] (3) Add 750g graphene / carbon black dispersion liquid, 300g water-based acrylic resin, 15g dispersant BYK190, 5g pH adjuster DMAE into the reaction kettle, adjust the pH to 8.5, stir at 800r / min for 1h, and obtain Environmentally friendly graphene-carbon black composite conductive coating T1;

[0068] Results The conductive paint T1 prepared above was coated on ABS board, tinplate board and ...

Embodiment 2

[0071] This embodiment is used for illustrating and adopting the method of the present invention to prepare graphene-carbon black composite conductive paint

[0072] (1) Add 279g water-based acrylic resin, 21g water, 9.75g dispersant SN-5027, 3.25g dispersant 760W, 4.5g defoamer 901W and 570g water-based graphene into the stirring tank, at room temperature, at 800r / min Stir for 50min at a rotating speed, then add 180g of conductive carbon black, and stir for 2h at a rotating speed of 1250r / min;

[0073] (2) The mixture of step (1) is then put into a grinder, ground to a fineness of 1 μm, and discharged to obtain a graphene / carbon black dispersion;

[0074] (3) 810g graphene / carbon black dispersion, 300g styrene-acrylic emulsion, 18g dispersant BYK190, 5.3g pH regulator DMAE, 78g film-forming agent dodecyl alcohol ester, 4g drying accelerator diethylene glycol ether Add 4g of thickener RM-8W into the reaction kettle, adjust the pH to 9.0, and stir for 1.5h at 800r / min to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com