Preparation method of carbon nanofiber electrode material based on MOFs derived metal oxide

A carbon nanofiber, electrode material technology, applied in the direction of active material electrodes, negative electrodes, battery electrodes, etc., can solve the problem of not taking into account the easy agglomeration of MOFs particles, and achieve an improved reversible specific capacity, easy operation, and environmental friendliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

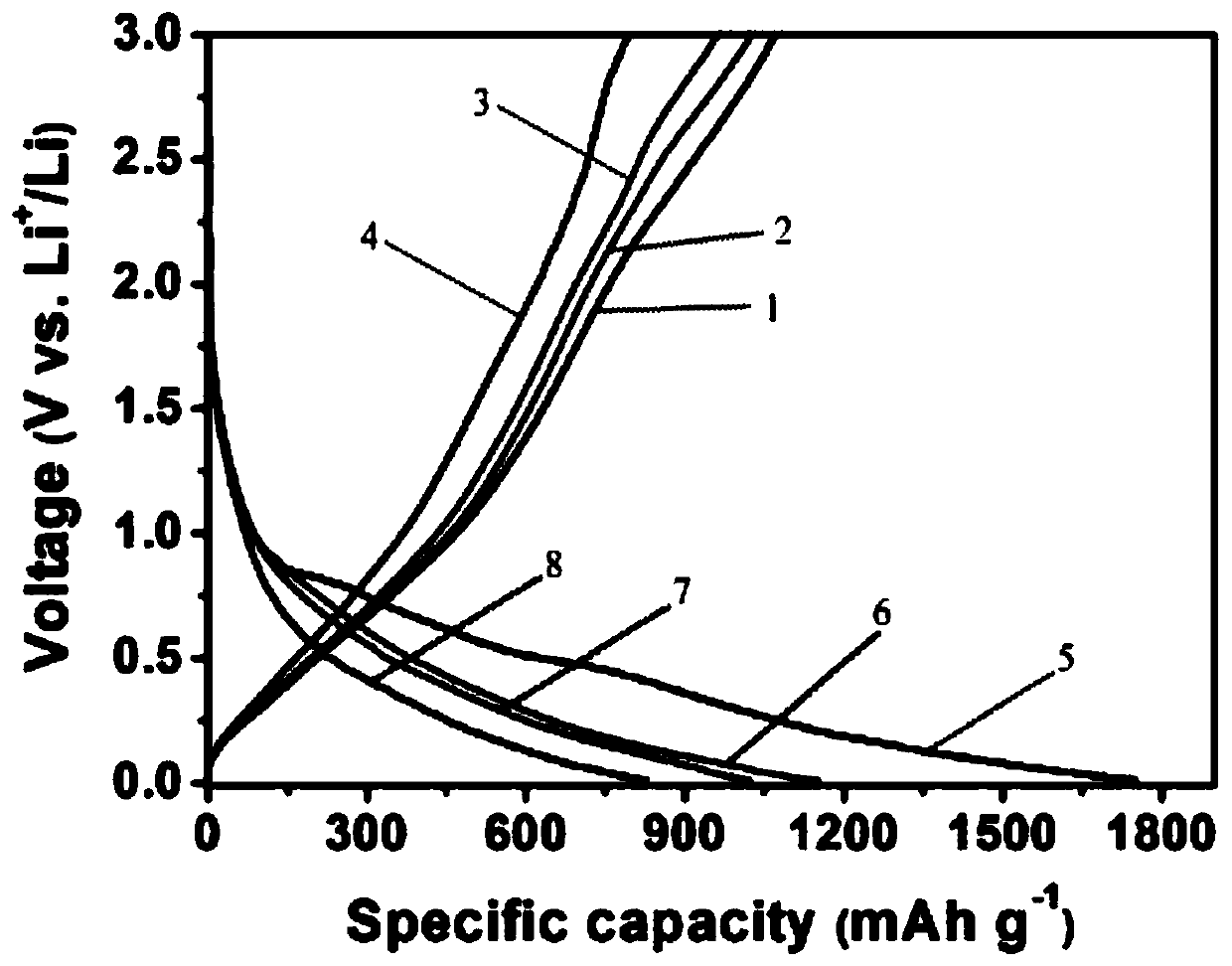

Embodiment 1

[0027] A preparation method based on MOFs derived metal oxide carbon nanofiber electrode material, comprising the steps of:

[0028] Step 1: Weigh 1.1158g of zinc nitrate and dissolve it in 30mL of methanol, weigh 1.2337g of 2-methylimidazole and dissolve it in 30mL of methanol, then mix the two solutions and stir for 10-30min to form a white suspension. Finally, after standing and aging at room temperature for 24 hours, centrifuge, wash with methanol and deionized water several times, and vacuum-dry at 70°C to obtain ZIF-8 nanoparticles with a particle size of 100-120nm;

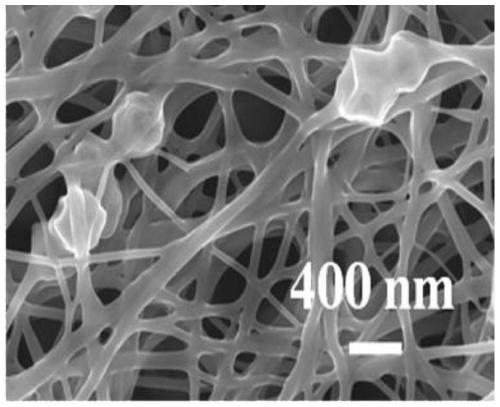

[0029] Step 2: Weigh 0.3g of ZIF-8 nanoparticles and ultrasonically disperse them in 6mL of DMF solution, then add 0.4g of PAN fibers, stir at 70°C for 5h to form a spinning precursor solution, and then spin the spinning precursor The solution was transferred to a 10mL syringe for electrospinning, and the current collector was copper foil. After spinning, a ZIF-8@PAN precursor film was formed, and it was va...

Embodiment 2

[0036] A preparation method based on MOFs derived metal oxide carbon nanofiber electrode material, comprising the steps of:

[0037] Step 1: Weigh 1.1158g of zinc nitrate and dissolve it in 30mL of methanol, weigh 1.2337g of 2-methylimidazole and dissolve it in 30mL of methanol, then mix the two solutions and stir for 10-30min to form a white suspension. Finally, after standing and aging at room temperature for 24 hours, centrifuge, wash with methanol and deionized water several times, and vacuum-dry at 70°C to obtain ZIF-8 nanoparticles with a particle size of 100-120nm;

[0038] Step 2: Weigh 0.4g of ZIF-8 nanoparticles and ultrasonically disperse them in 6mL of DMF solution, then add 0.48g of PAN fiber, stir at 70°C for 5h to form a spinning precursor solution, and then spin the spinning precursor The solution was transferred to a 10mL syringe for electrospinning, and the current collector was copper foil. After spinning, a ZIF-8@PAN precursor film was formed, and it was va...

Embodiment 3

[0045] A preparation method based on MOFs derived metal oxide carbon nanofiber electrode material, comprising the following steps:

[0046] Step 1: Dissolve 0.748g of ferric chloride and 0.46g of terephthalic acid in 60mL of DMF solution and stir for 20-30min to obtain a mixed solution; Heated to 120°C in a hydrothermal reaction kettle, kept warm for 2 hours, cooled to room temperature, centrifuged at a speed of 8000r / min, washed repeatedly with DMF and absolute ethanol, and vacuum dried at 70°C for 12 hours. Obtain MIL-88 nanoparticles with a particle size of 600-700nm;

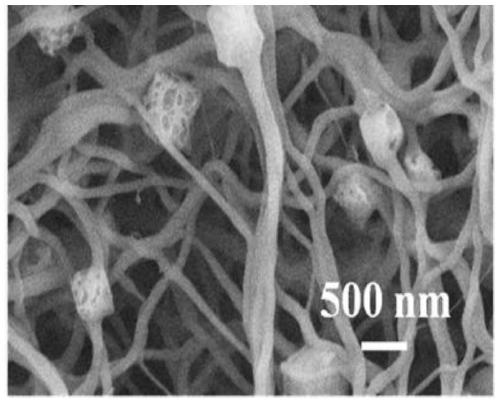

[0047] Step 2: Weigh 0.3g of MIL-88 nanoparticles and ultrasonically disperse them in 6mL of DMF solution, then add 0.4g of PAN fibers, and stir at 70°C for 5h to form a spinning precursor solution; the spinning precursor solution Transfer to a 10mL syringe for electrospinning. The current collector is copper foil. After spinning, a MIL-88@PAN precursor film is formed. Place it at 60°C for 12 hours in vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com