Anticorrosion thermal insulation heat reflecting paint for storage tank and preparation method thereof

A reflective coating, warm technology, applied in anti-corrosion coatings, reflective/signal coatings, epoxy coatings, etc., can solve the problem that the primer coating does not consider the anti-corrosion requirements of steel storage tanks, does not consider the anti-fouling performance of the coating, shortens the Equipment service life and other issues, to achieve excellent anti-aging and yellowing performance, good anti-corrosion effect, excellent heat insulation and heat reflection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

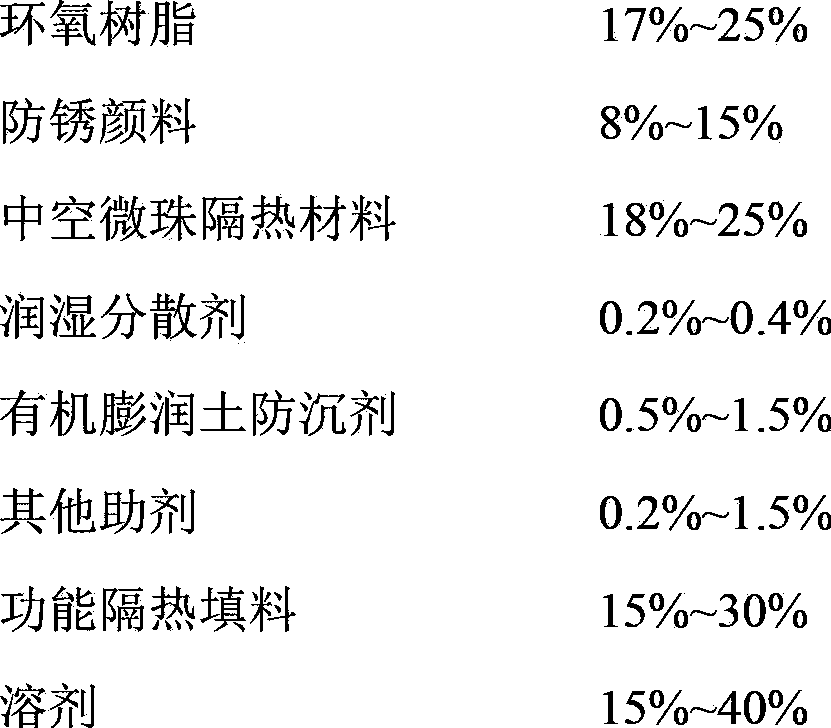

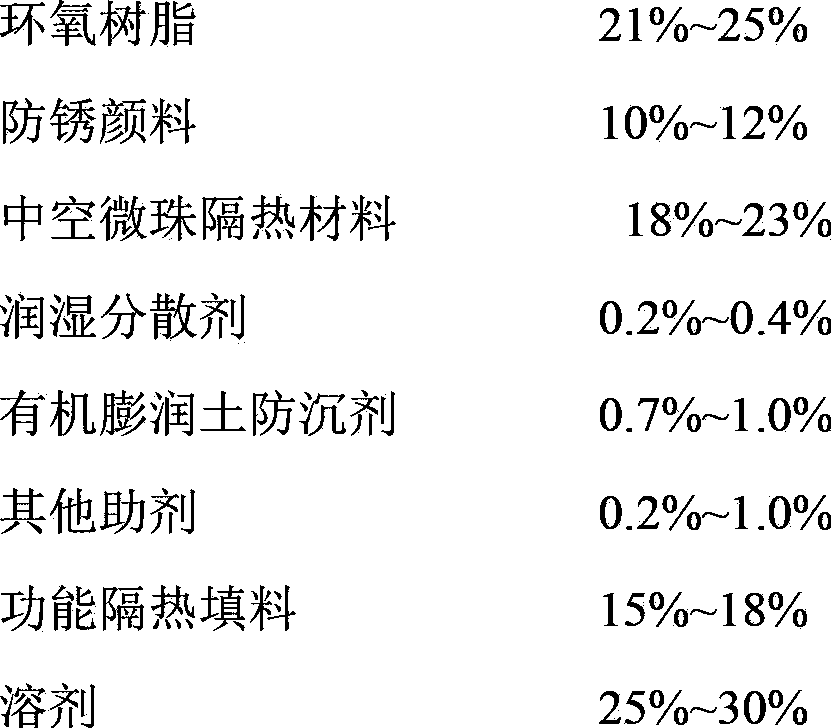

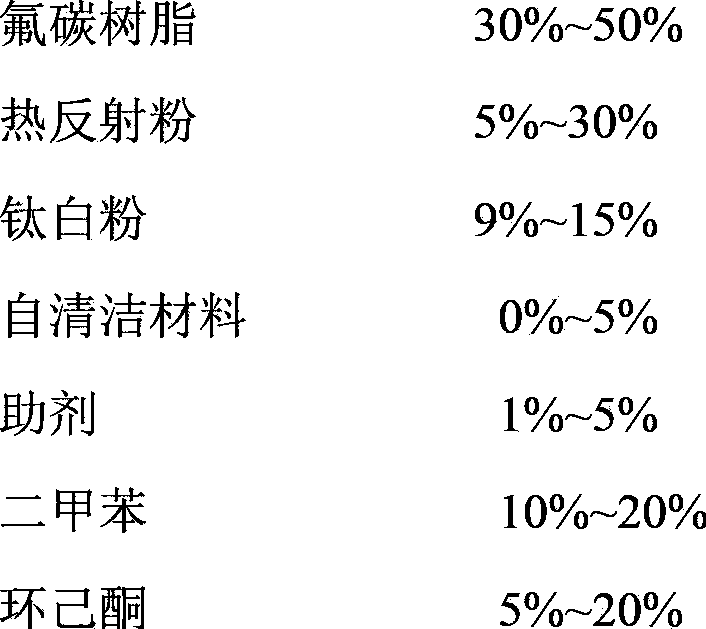

[0075] Primer: See Table 1 for the formula.

[0076] Table 1

[0077] raw material

Example 1

Example 2

Example 3

Example 4

[0078] Component A formula

E20 epoxy resin

17

0

19

0

E44 epoxy resin

0

16

0

17

DEN 431 epoxy resin

6

5

5

6

8

5

4

0

0

3

0

0

Iron Oxide Red

2

0

0

1

0

3

0

10

Zinc borate

2

0

6

1.2

Glass cenospheres

20

18.2

22.05

22

BYK-ATU

0.3

0

0.25

0

BYK-AT-204

0

0.2

0

0.4

Organic bentonite anti-settling agent

0.7

0.8

0.8

1.0

Defoamer a, Tego airex 900

0.2

0

0.4

0

Defoamer b, BYK-141

0

0.8

0

1.0

hollow glass microspheres

15.3

...

Embodiment 1

[0090] Embodiment 1 preparation method:

[0091] Preparation of primer:

[0092] (1) Mix 17% of the total weight of E20 epoxy resin and 6% of DEN 431 epoxy resin, add 15% of the total weight of solvent and heat to dissolve, so that the solid weight content is 60%, and then add BYK-ATU, antirust Pigment, solvent with a total weight of 12%, other additives and functional heat-insulating fillers, grind, and the dispersion fineness of the pigment is qualified, add hollow glass microspheres, stir evenly, and add the remaining amount of solvent and adjust the viscosity to obtain the first component, The rotational viscosity of component A at 25°C is above 1.5pa.s;

[0093] (2) Mix and disperse polyamide epoxy curing agent and solvent to obtain component B;

[0094] The weight ratio of components A and B is that the ratio of the epoxy equivalent of component A to the active hydrogen equivalent molar ratio of component B is 1:1. After mixing components A and B, use them up within 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com