Waterborne inorganic zinc shop primer, and preparation and application thereof

A shop primer, inorganic zinc technology, applied in coatings, alkali metal silicate coatings, anti-corrosion coatings, etc., can solve problems such as low viscosity, affecting construction efficiency, and inability to meet the requirements of shop primer film thickness. The effect of excellent anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

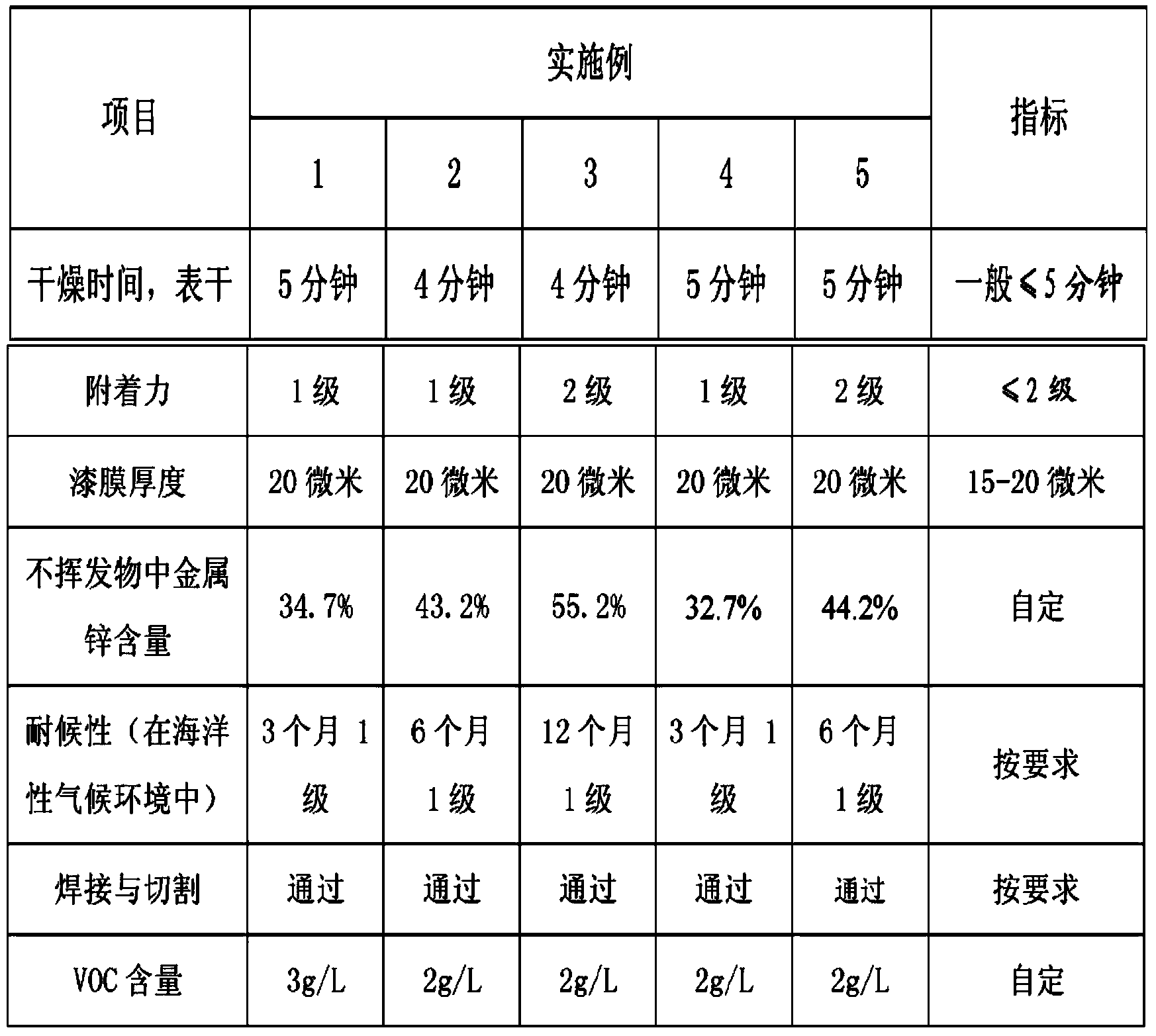

Examples

preparation example Construction

[0072] Preparation of base material: Add 200 kg of pure water, 5 kg of silicon dioxide, 1 kg of indium oxide, 1 kg of surfactant, and 3 kg of imidazoline quaternary ammonium salt into the paint mixing tank, and disperse for 10 minutes at a high speed of 1200 rpm. Then add the remaining powder and stir evenly to obtain the base material. The base material can be stored at room temperature for up to 6 months. After opening, it has good appearance, excellent fluidity and no deterioration.

[0073] Preparation of curing agent: Add 10 kg of acrylic acid monomer, 40 kg of styrene, 20 kg of methyl acrylate, and 20 kg of ethyl acrylate into the reaction kettle, heat to 93±5 degrees, react for 6 hours, add surfactant, defoaming agent, add water, and add lithium silicate after cooling to room temperature to obtain a curing agent.

[0074] The shop primer coating is prepared by uniformly mixing the base material and the curing agent at a weight ratio of 2:1.

Embodiment 2 6

[0075] Embodiment 2 anticorrosion water-based shop primer for six months

[0076] The formula of base material is as follows:

[0077] Bentonite 12kg

[0078] Spherical zinc powder (particle size is 2-5 microns) 456 kg

[0079] Flake zinc powder (long diameter 15-20 microns) 144 kg

[0081] Magnesium silicate 115 kg

[0082] Ferrophosphorus powder 124 kg

[0083] 400 kg of water

[0085] MBTS (3 methyl thiophene) 4.5 kg

[0086] Surfactant RHODAPON PEH 1 kg (Rhodia Corporation)

[0087] Anti-sedimentation agent ST-3 2 kg (Shangtian Tifengsen Bentonite Factory, Xinyang City, Henan Province)

[0088] Defoamer BYK-019 0.7 kg (Bick company)

[0089] The formula of curing agent is as follows:

[0090] Sodium silicate 600 kg

[0091] Styrene 40 kg

[0092] Methyl acrylate 20kg

[0093] Ethyl acrylate 20 kg

[0094] 280 kg of water

[0095] Dispersant E-1308 10 kg (Jiangsu Haian Petrochemical Co., Ltd.)

[0...

Embodiment 3

[0100] Embodiment 3 12 months anticorrosion water-based shop primer

[0101] The formula of base material is as follows:

[0102] Bentonite 10kg

[0103] Silica 15 kg

[0104] Spherical zinc powder (particle size is 2-5 microns) 540 kg

[0105] Flake zinc powder (long diameter 15-20 microns) 40 kg

[0106] Phosphorus powder 50kg

[0107] 170 kg of water

[0108] Bismuth oxide 2 kg

[0109] DMTD 5kg

[0110] Heavy calcium 207 kg

[0111] Surfactant RHODAPON BOS 1 kg (Rhodia Corporation)

[0112] Anti-sedimentation agent ST-4 2.5 kg (Shangtianti Fengsen Bentonite Clay Factory, Xinyang City, Henan Province)

[0113] Defoamer BYK-019 0.8 kg (Bick company)

[0114] The formula of curing agent is as follows:

[0115] Potassium silicate 600 kg

[0116] Acrylic monomer: 20 kg

[0117] Styrene 40 kg

[0118] Methyl acrylate 20kg

[0119] Ethyl acrylate 20 kg

[0120] Water 310 kg

[0121] Dispersant E-1306 10 kg (Jiangsu Haian Petrochemical Co., Ltd.)

[0122] Defoame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com