Low-cost high-temperature-resistant coating

A low-cost technology for high-temperature resistant coatings, applied in the field of high-temperature resistant coatings and silicone high-temperature resistant coatings, can solve the problems of high cost and poor anti-corrosion performance, and achieve the effect of low cost and good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 5

[0017] Polyvinyl butyral (8-10S PVB, Shanghai Sixi)

[0018] Silicate (tetraethyl orthosilicate Xinya Chemical)

[0019] Activator (Zinc Chloride Shandong Shenlu Zinc Industry)

[0020] Dispersant (BYK161 BYK)

[0021] Anti-settling agent (201P Deqian Chemical)

[0022] Mixed solvent: It is made by mixing toluene, xylene, n-butanol, ethanol, isopropanol, etc. in equal proportions.

[0023] Alcohol solvent: It is made by mixing alcohol solvents such as ethanol, n-butanol, and isopropanol in equal proportions.

Embodiment 1

[0024] The black high temperature resistant pigment in embodiment 1 and embodiment 2 adopts copper chrome black, adopts iron chrome black in embodiment 3 and embodiment 4, adopts graphite black in embodiment 5.

[0025] The high-temperature-resistant fillers in Examples 1 to 5 are respectively kaolin, talcum powder, barium sulfate, heavy calcium, and light calcium.

[0026] The antirust pigments in Examples 1 to 5 are respectively mica iron oxide, zinc chrome yellow, strontium chrome yellow, zinc phosphate, and zinc molybdate.

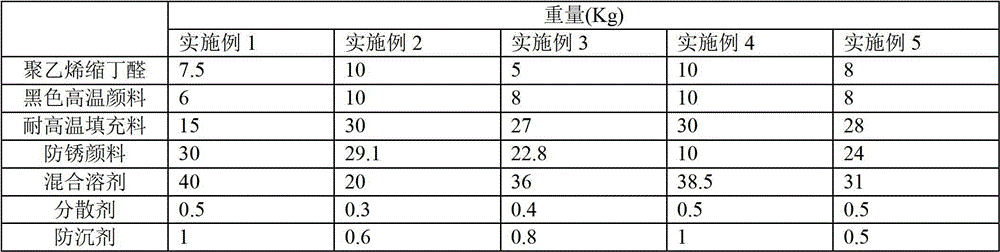

[0027] The weight ratio of components is shown in Table 1 and Table 2.

[0028] Table 1 Component A formula proportion of embodiment 1~embodiment 5

[0029]

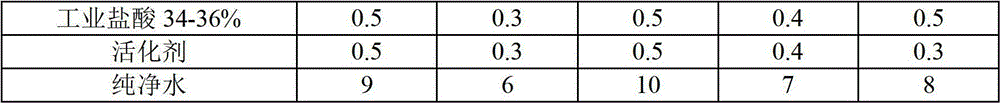

[0030] Table 2 Component B formula proportion of embodiment 1~embodiment 5

[0031]

[0032]

[0033] The preparation method is:

[0034] A component:

[0035] (1) Dissolve polyvinyl butyral into a solution with a mixed solvent of 1 / 3 to 2 / 3, and the detection fineness is within 15 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com