Low-temperature quick-curing epoxy coating and preparation method thereof

A fast-curing, epoxy coating technology, used in epoxy resin coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve problems such as normal construction cannot be guaranteed, and achieve good surface condition, excellent anti-corrosion performance, and excellent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

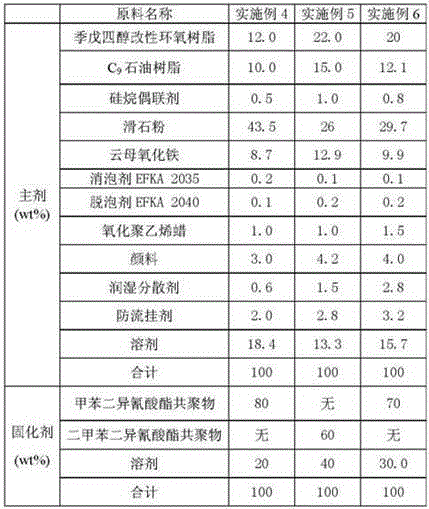

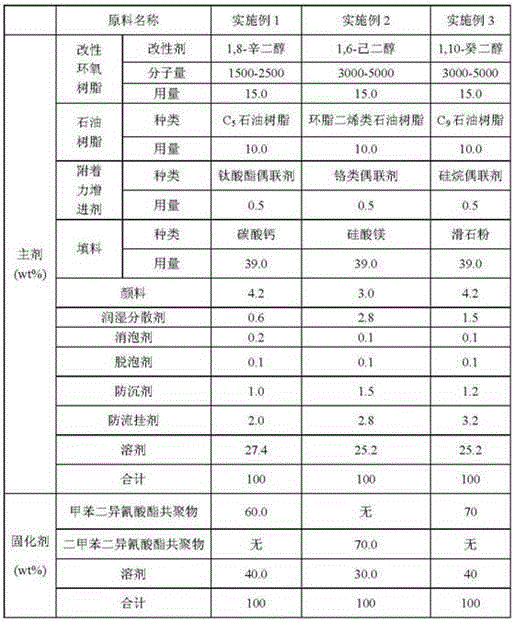

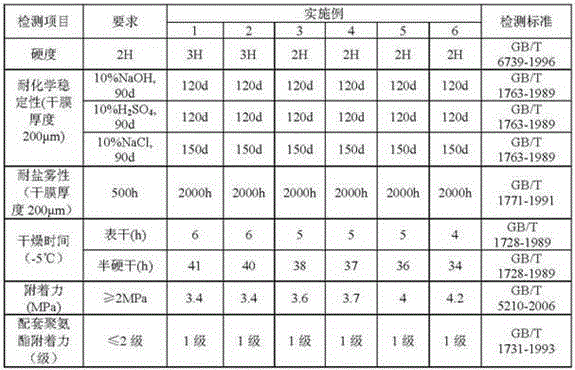

[0027] (1) Preparation of the main ingredient: first add modified epoxy resin and petroleum resin according to the formula amount, slowly add anti-settling agent under stirring, disperse at high speed for about 10 minutes until it becomes a uniform viscous slurry liquid, then add wetting and dispersing agent and Defoamer, add part of the solvent (xylene and ethyl acetate mixture), add various pigments and fillers while stirring, continue to stir at high speed for 20 minutes until the dispersion is uniform, then add defoamer, adhesion promoter, anti-flow Stir the hanging agent, adjust the solid content with a small amount of solvent, filter and pack as the main agent.

[0028] (2) Preparation of curing agent: Mix and disperse toluene diisocyanate copolymer or xylene diisocyanate copolymer and solvent evenly according to the formula, filter and pack to obtain the curing agent. Toluene diisocyanate copolymer or xylene diisocyanate copolymer are products of Takeda Industrial Pharm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com