Contact type inshore fishing boat anti-fouling paint and preparation method thereof

An antifouling paint and contact type technology, applied in the field of antifouling paint, can solve the problems of strong irritating odor of capsaicin and strong irritating environment, achieve excellent antifouling performance, good manufacturing and construction environment, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

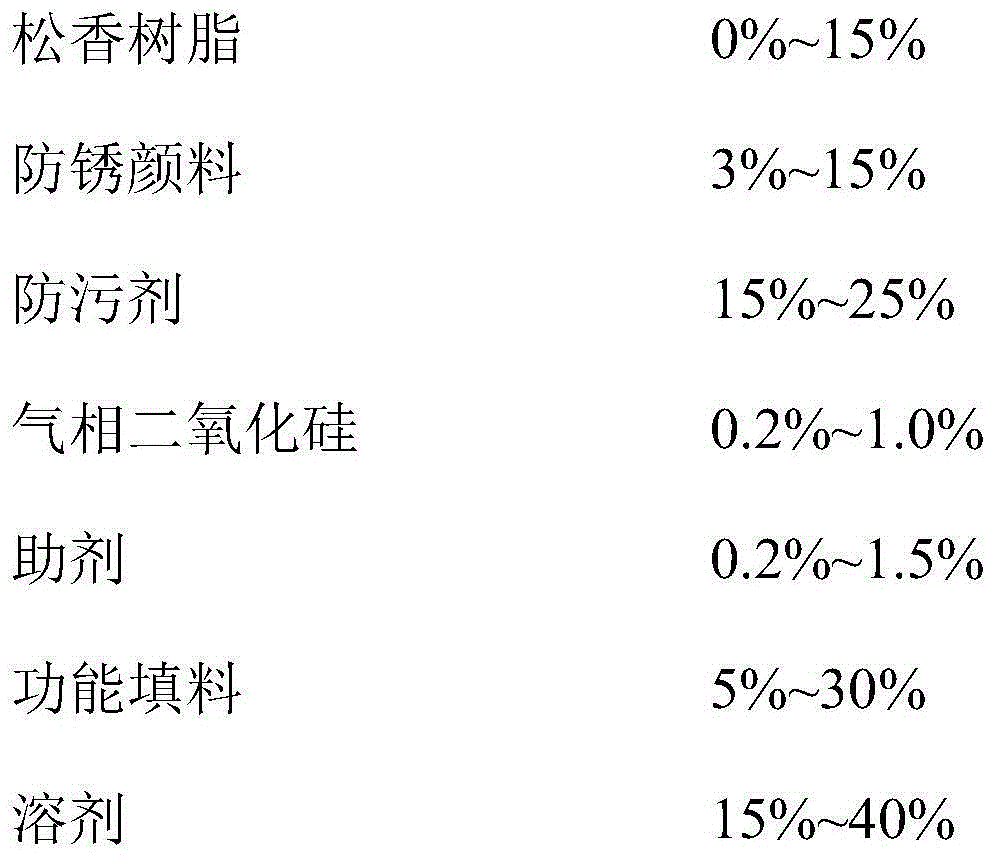

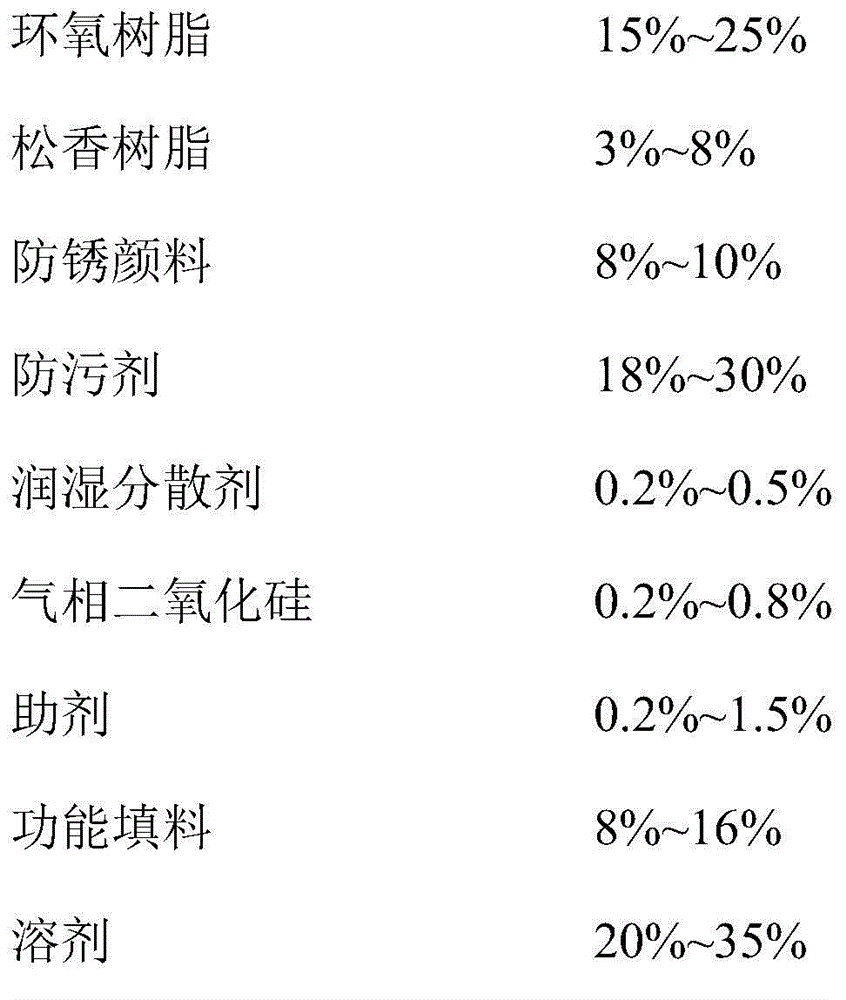

[0047] Antifouling paint: See Table 1 for the formulation. (weight percent)

[0048] Table 1

[0049]

[0050] The distribution ratio of Group A and Group B is (8-12): 1, and the specific calculation and actual test shall prevail.

[0051]The antifouling agent in the embodiment is silver-copper ion nanocomposite powder of α-zirconium phosphate, and adopts the product of NAFUR series antifouling agent produced by Shanghai Runhe Nano Material Technology Co., Ltd.;

Embodiment 1

[0052] Embodiment 1 preparation method:

[0053] Preparation of antifouling paint:

[0054] (1) Heat and dissolve epoxy resin and 18% solvent by total weight, add wetting and dispersing agent, rosin resin, anti-rust pigment, 3% solvent by total weight, other additives in turn, grind, add dispersed anti-fouling Add the anti-sedimentation agent silicon dioxide and the rest of the solvent to obtain component A. The rotational viscosity of component A at 25°C is above 1.0pa.s;

[0055] (2) Mix polyamide epoxy curing agent and solvent, stir and mature to obtain component B;

[0056] The weight ratio of components A and B is that the ratio of the epoxy equivalent of component A to the active hydrogen equivalent molar ratio of component B is 1:1. After mixing components A and B, use them up within 4 hours.

[0057] The preparation method of embodiment 2~3 is with embodiment 1, wherein:

[0058] The preparation method of antifouling paint is as follows:

[0059] Heat and dissolve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com