Profiled steel sheet

A technology of profiled steel plates and roofs, applied to floors, structural elements, building components, etc., can solve the problems of lack of steel protective layer thickness and failure to meet the requirements of 50-year corrosion life, and achieve good fire resistance and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

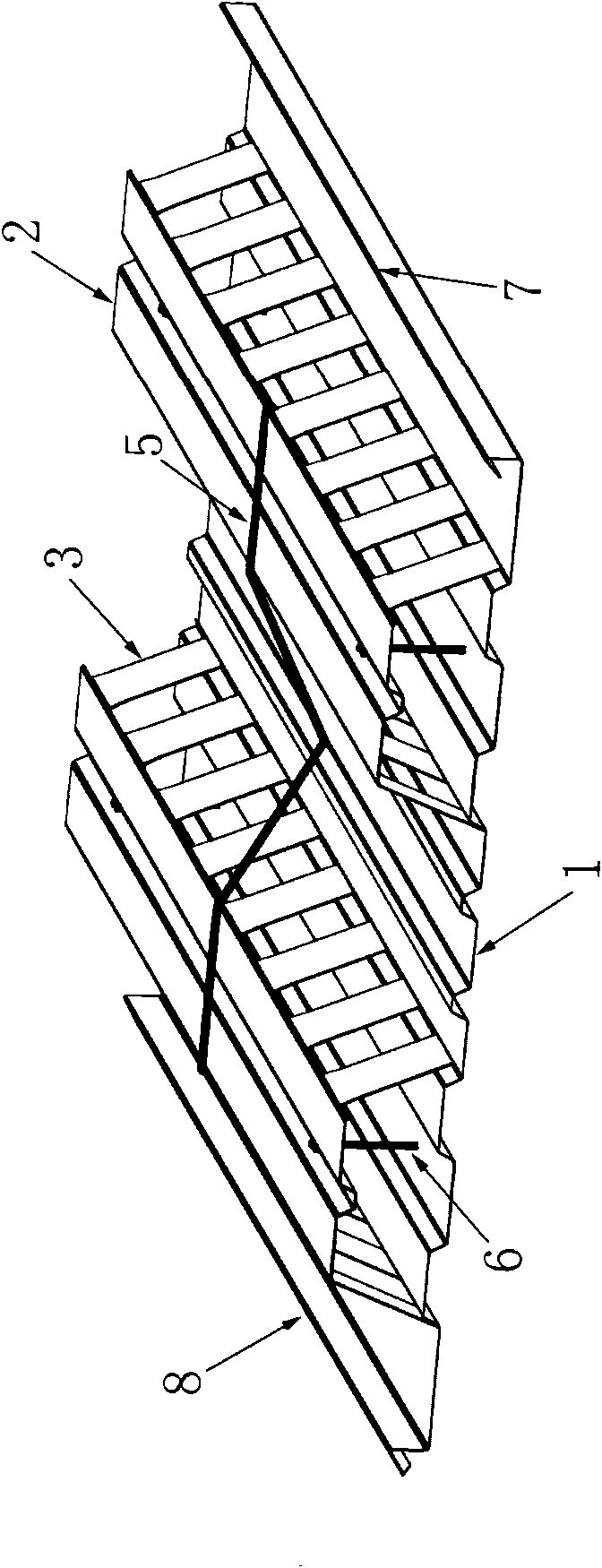

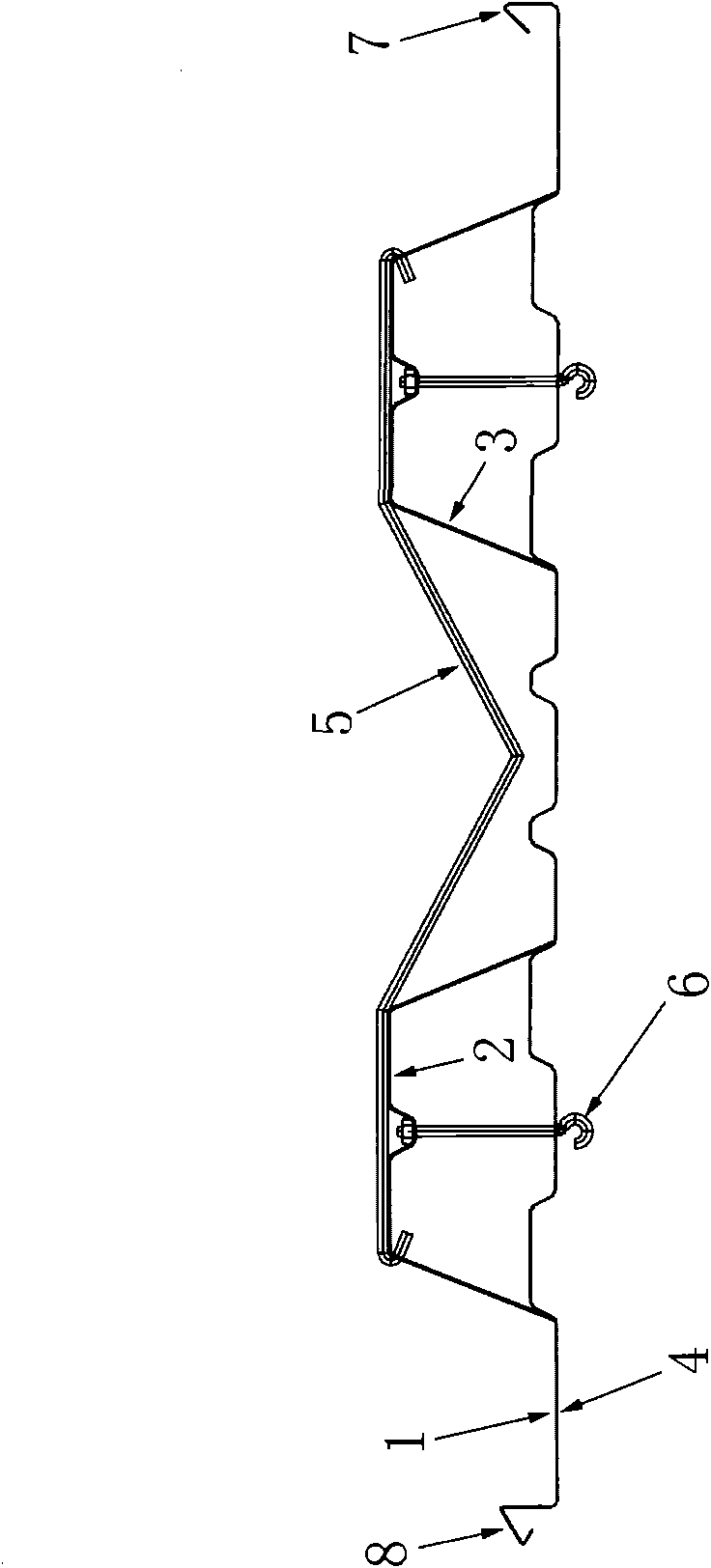

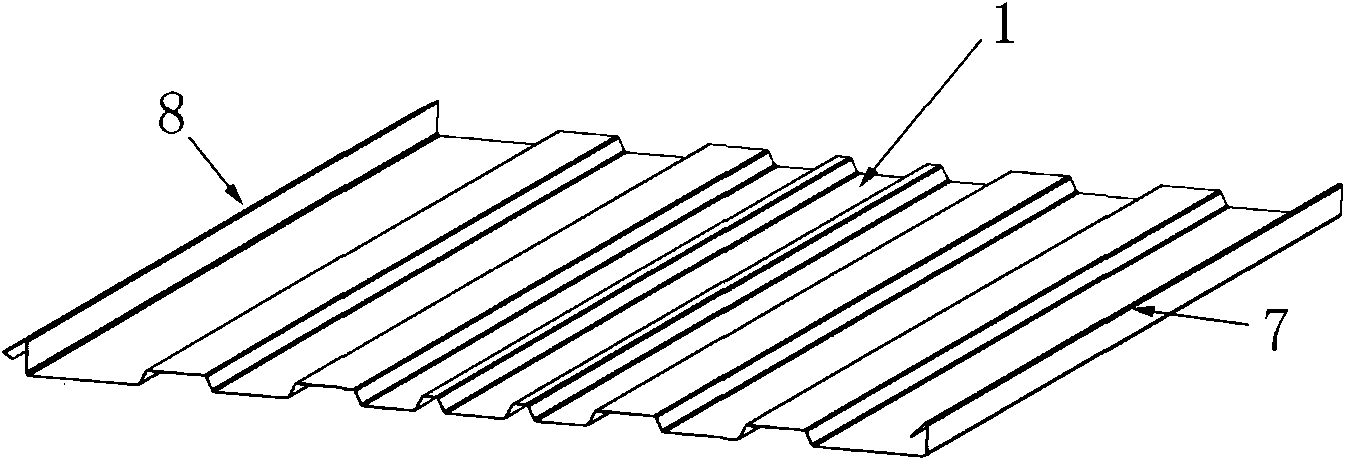

[0019] refer to figure 1 , figure 2 and image 3 , which shows the bottom plate 1 of profiled steel plate. In use, the bottom plate 1 is made of cold-rolled steel coils or cold-rolled galvanized steel coils through cold working. There are stiffening ribs in the longitudinal direction of the bottom plate 1, and the typical height of the ribs is between 10mm and 15mm. The thickness of the steel plate from which the base plate is made can vary, with typical thicknesses ranging from 0.5 mm to 1.0 mm. Both sides of the bottom plate are bent into longitudinal sides 7 and 8 that can engage with each other. When multiple boards are laid side by side, the longitudinal sides 7 extend into the longitudinal sides 8 and engage with them.

[0020] Figure 4 It shows the top plate 2 and the web 3 which are cut from the same steel plate and connected into one body, and the webs 3 are alternately and intermittently arranged on both sides of the top plate 2 . In order to reduce the degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com