Water-based anti-corrosion paint and preparing method of water-based anti-corrosion paint

An anti-corrosion coating, water-based technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of environmental damage, destruction of water biological chain, water eutrophication, etc., and achieve the effect of excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

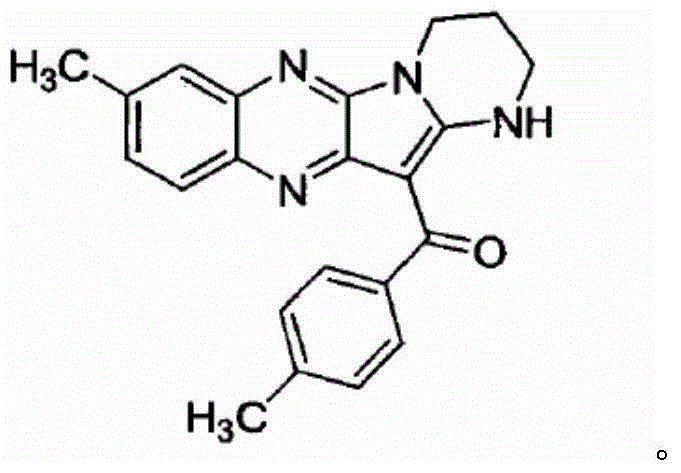

Image

Examples

preparation example Construction

[0021] The preparation of embodiment water-based anticorrosion coating

[0022] Weigh 0.6 kg of SN-NXZ, 9 kg of sodium polyacrylate, 0.6 kg of polyvinyl alcohol, and 0.8 kg of Add 20 kg of water, stir for 20 minutes at a speed of 200rpm, then add 150 kg of AB-EP-20 water-based epoxy resin emulsion, stir for 20 minutes at a speed of 800rpm, then transfer to a sand mill with a speed of 1200rpm Sand mill at a rotating speed for 60 minutes, filter with a 100-mesh sieve, add 1.6 kg of Tego Glide B148 to the filtrate, and stir at a rotating speed of 100 rpm for 10 minutes to obtain the product.

experiment example

[0024] According to the national standard GB 1727-79 "Paint Film Preparation Method" requires the water-based epoxy anti-corrosion paint film prepared in Example 1, after the base material is polished, derusted, etc., the surface is cleaned, wiped with absolute ethanol, and dried in the air dry and keep it dry. When preparing the paint film, the prepared paint is evenly brushed on the substrate with a wolf hair brush, the brushed coating is cured at room temperature, and various performance tests are carried out after drying at room temperature.

[0025] The anti-corrosion performance of the coating is to evaluate the anti-corrosion performance by letting the sample plate painted with paint be visually inspected under the specified corrosion conditions to check the foaming and falling off of the sample plate after soaking in the corrosive medium for a certain period of time.

[0026] When carrying out the corrosion-resistant medium immersion test, select 3 parallel test plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com