Process for preparing fluorocarbon protective paint of aluminium alloy anodization

A protective coating and anodizing technology, which is applied in the field of aluminum alloy anodized fluorocarbon protective coating and its preparation, can solve the problems of narrow operating temperature range, poor acid resistance, poor acid resistance and alkali resistance, and can meet the protection requirements and anti-corrosion performance. Good, high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

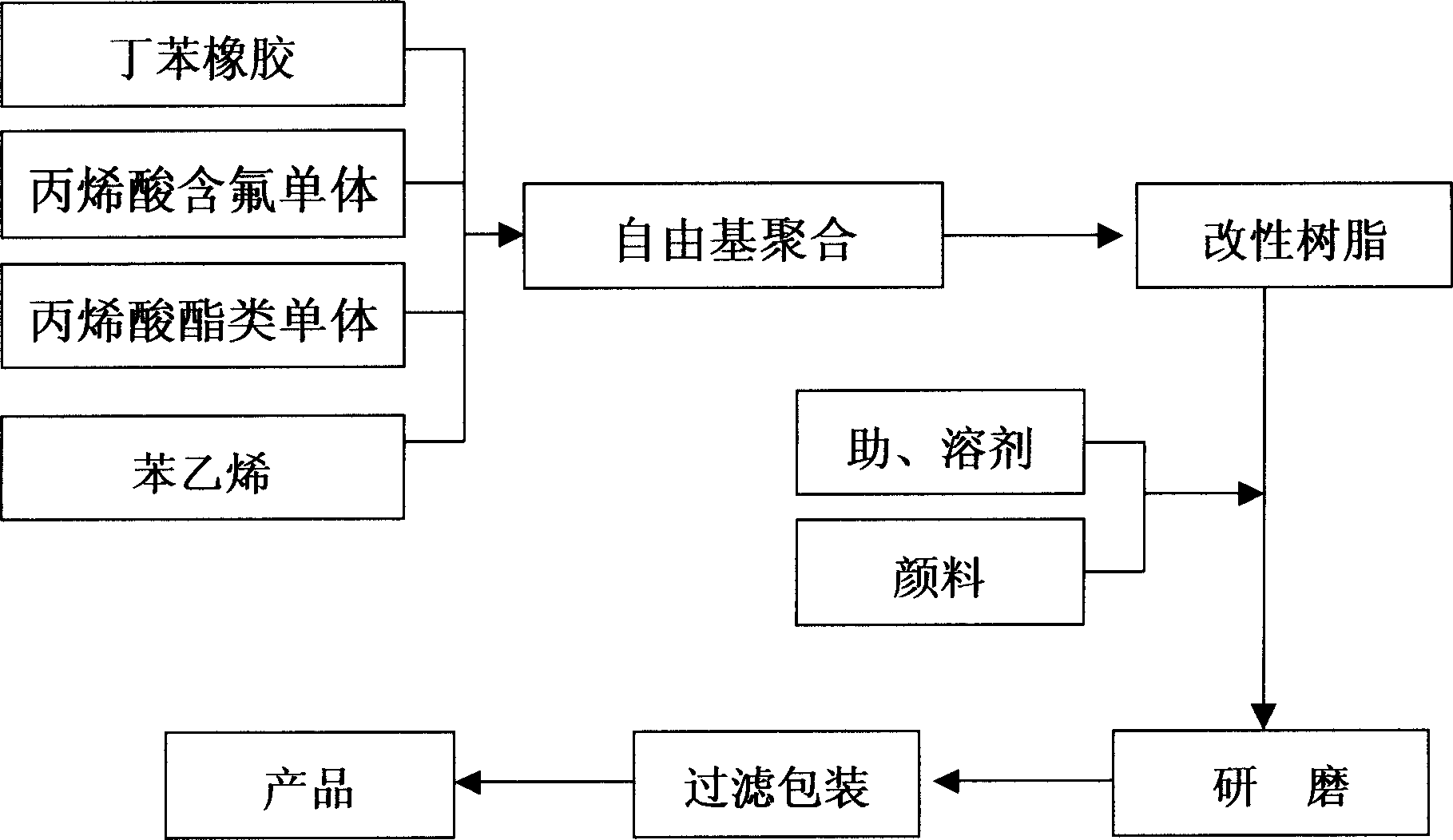

Method used

Image

Examples

Embodiment 1

[0028] This example demonstrates the preparation method of the rubber-modified fluorine-containing acrylic resin binder and the aluminum alloy anodized fluorocarbon protective coating of the present invention.

[0029] Mixed solvent 400g (wherein: cyclohexanone 100g, butyl acetate 200g, ethyl acetate 100g) into the reaction device, hexafluorobutyl acrylate 31g, styrene-butadiene rubber 24g, styrene 66g, methyl methacrylate 57g, 66 g of butyl acrylate and 57 g of 2-ethylhexyl acrylate were mixed evenly, 10% of the mixed monomers were added to the reaction device, stirring was started, the temperature was raised to 120° C., and the temperature was maintained under reflux for 30 minutes. The remaining 90% mixed monomers are mixed with mixed solvent 200g (cyclohexanone 50g, butyl acetate 100g, ethyl acetate 50g), dibenzoyl peroxide 5.4g, and added to the dropping tank for uniform dropwise addition, about 150-180 g Dropped in minutes. Insulation refluxed for 30 minutes, dripped in...

Embodiment 2

[0032] The formulation of rubber modified resin is as follows:

[0033] Hexafluorobutyl acrylate 63g

[0034] Styrene Butadiene Rubber 15g

[0035] Styrene 51g

[0036] Methyl methacrylate 60g

[0037] Butyl Acrylate 60g

[0038] 2-Ethylhexyl Acrylate 51g

[0039] Cyclohexanone 175g

[0040] Butyl acetate 350g

[0041] Ethyl acetate 175g

[0042] Dibenzoyl Peroxide 6g

[0043] The solid content of the rubber-modified fluorocarbon resin is 30%, the fluorine content is 10.1% of the solid content of the resin, and the content of styrene-butadiene rubber is 5% of the solid content of the resin.

[0044] The formula of anodized protective coatings for aluminum alloys is as follows:

[0045] Rubber Modified Acrylic Resin 1000g

[0046] Phthalocyanine Blue 20g

[0047] Fumed silica 20g

[0048] DEUCHEM 902 0.5g

[0049] Organic bentonite 0.5g

[0050] The viscosity of the aluminum alloy anodized protective coating is 25s and the fineness is 10μm.

Embodiment 3

[0052] The formulation of rubber modified resin is as follows:

[0053] Dodecafluorooctyl Acrylate 93g

[0054] Styrene Butadiene Rubber 9g

[0055] Styrene 50g

[0056] Methyl methacrylate 49g

[0057] Butyl Acrylate 54g

[0058] 2-Ethylhexyl Acrylate 54g

[0059] Cyclohexanone 175g

[0060] Butyl acetate 350g

[0061] Ethyl acetate 175g

[0062] Dibenzoyl Peroxide 6g

[0063] The solid content of the rubber-modified fluorocarbon resin is 30%, the fluorine content is 15% of the solid content of the resin, and the content of styrene-butadiene rubber is 3% of the solid content of the resin.

[0064] Anodized protective coatings are formulated as follows:

[0065] Rubber Modified Acrylic Resin 1000g

[0066] Phthalocyanine Blue 20g

[0067] Fumed silica 20g

[0068] DEUCHEM 902 0.5g

[0069] Organic bentonite 0.5g

[0070] The viscosity of the aluminum alloy anodized protective coating is 20s and the fineness is 5μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com