Negative-pressure liquid feeding device based on liquid core wave guide pipe

A technology of a liquid inlet device and a waveguide, which is applied in the field of measuring instruments, can solve the problems of increased cleaning operations, high requirements for operational accuracy, and large volume of syringe pumps, and achieve the effects of avoiding cross-contamination, avoiding optical path interference, and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

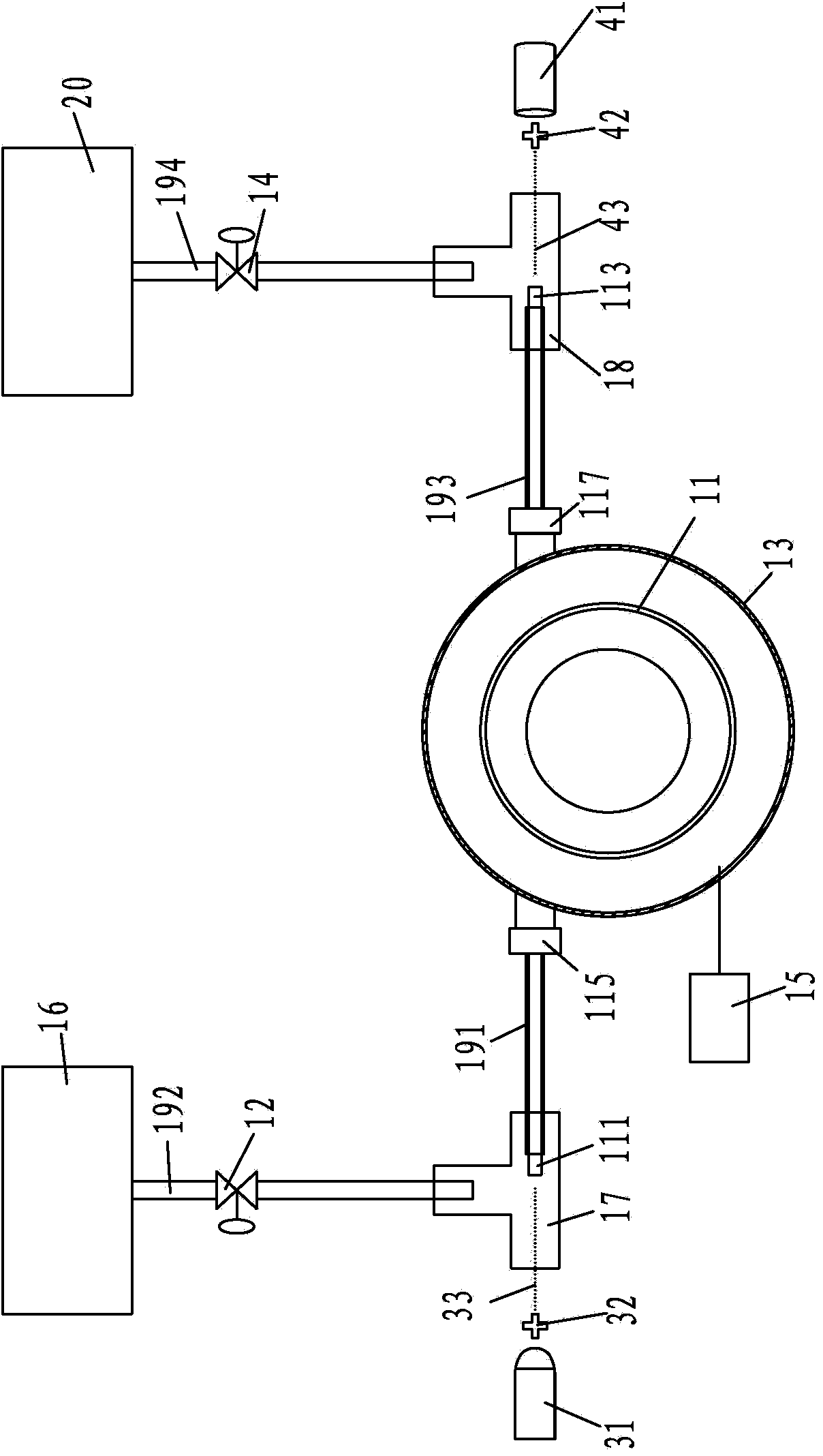

[0008] Such as figure 1 As shown, the negative pressure liquid inlet device based on the liquid core waveguide of the present invention includes a liquid core waveguide 11, a vacuum chamber 13, a vacuum pump 15 and left and right joints 17, 18, the vacuum chamber 13 is a closed cavity, and the vacuum pump 15 and the vacuum The inner cavity of the cavity 13 is connected, the main part of the liquid core waveguide 11 is arranged in the vacuum cavity 13 and the sampling end 111 and the detection end 113 of the liquid core waveguide 11 all protrude out of the vacuum cavity 13, and the liquid core waveguide 11 Connectors 115 and 117 are respectively provided between the main body and the sampling end 111 and the detection end 113. The sampling end 111 of the liquid core waveguide 11 is covered with a first sampling capillary line 191, and the first sampling capillary line 191 is sleeved There is a left joint 17, and the left joint 17 is sleeved with a second sampling capillary line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com