High-temperature abrasive resistant ball valve with fixed ball and floating valve seat

A floating valve seat, high-temperature wear-resistant technology, applied in the parts, valve details, valve devices, etc. in contact between the valve element and the valve seat. It can achieve the effect of good sealing, improved concentricity and easy assembly due to problems such as poor degree of freedom of the valve seat and limited operating temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

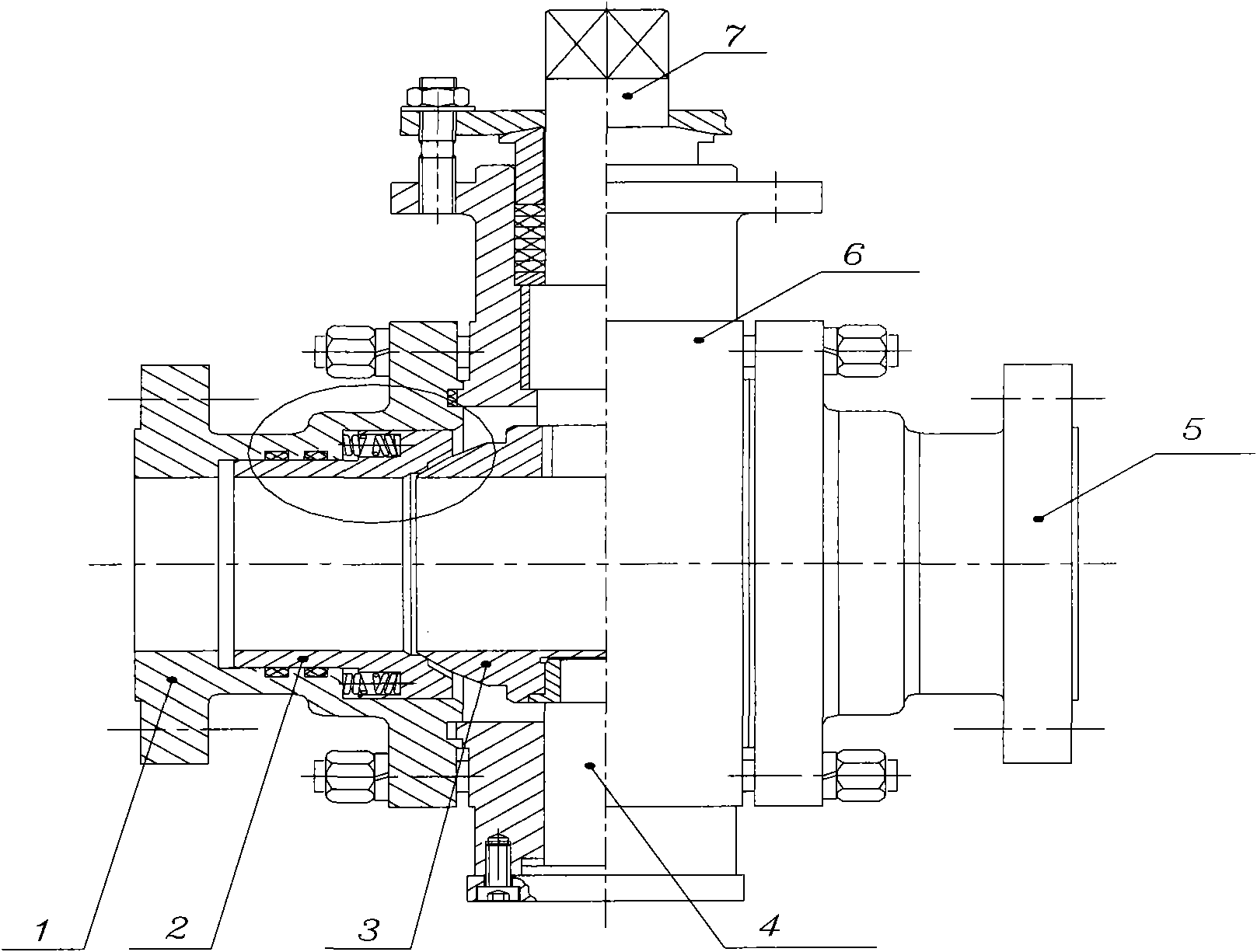

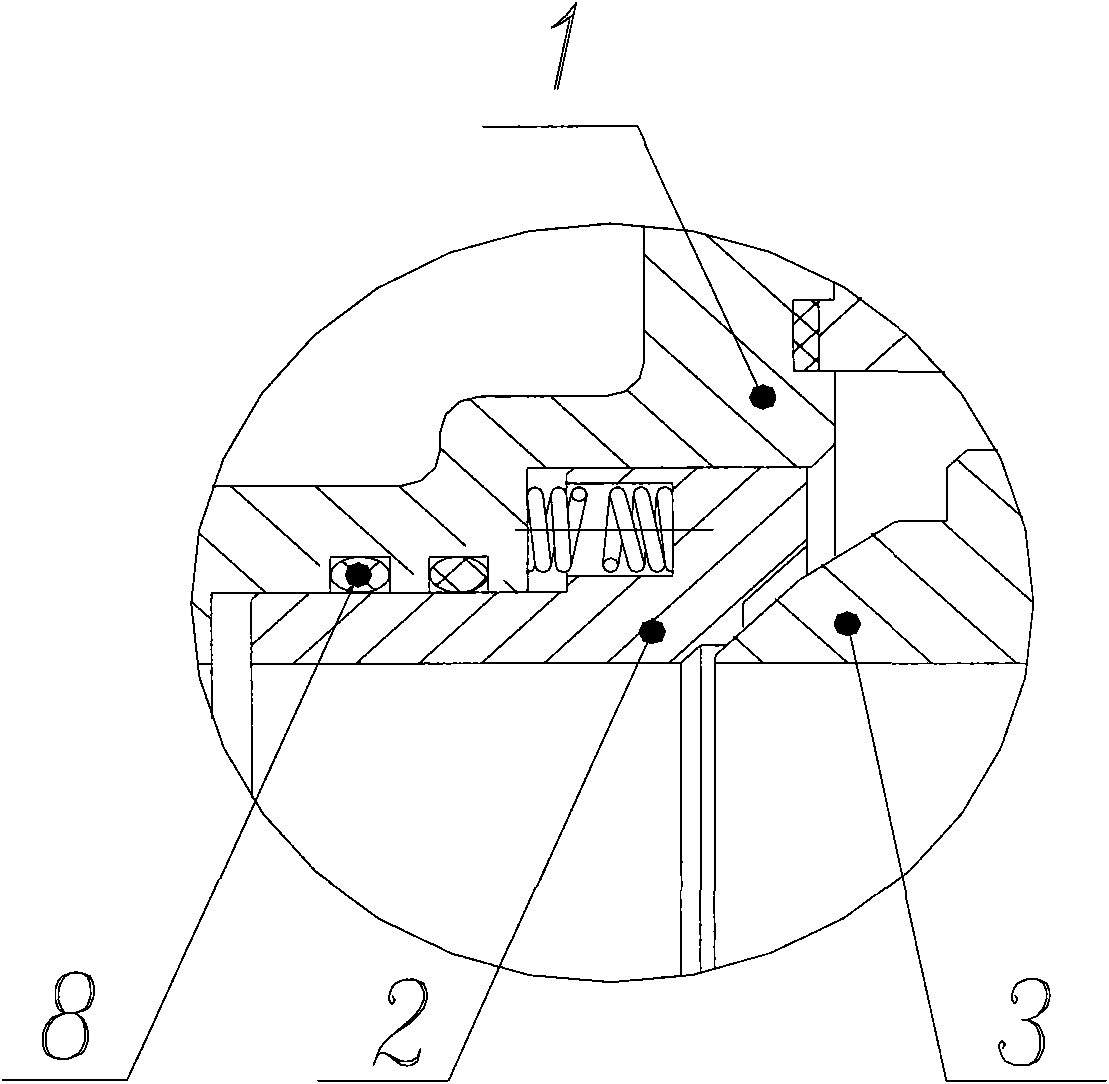

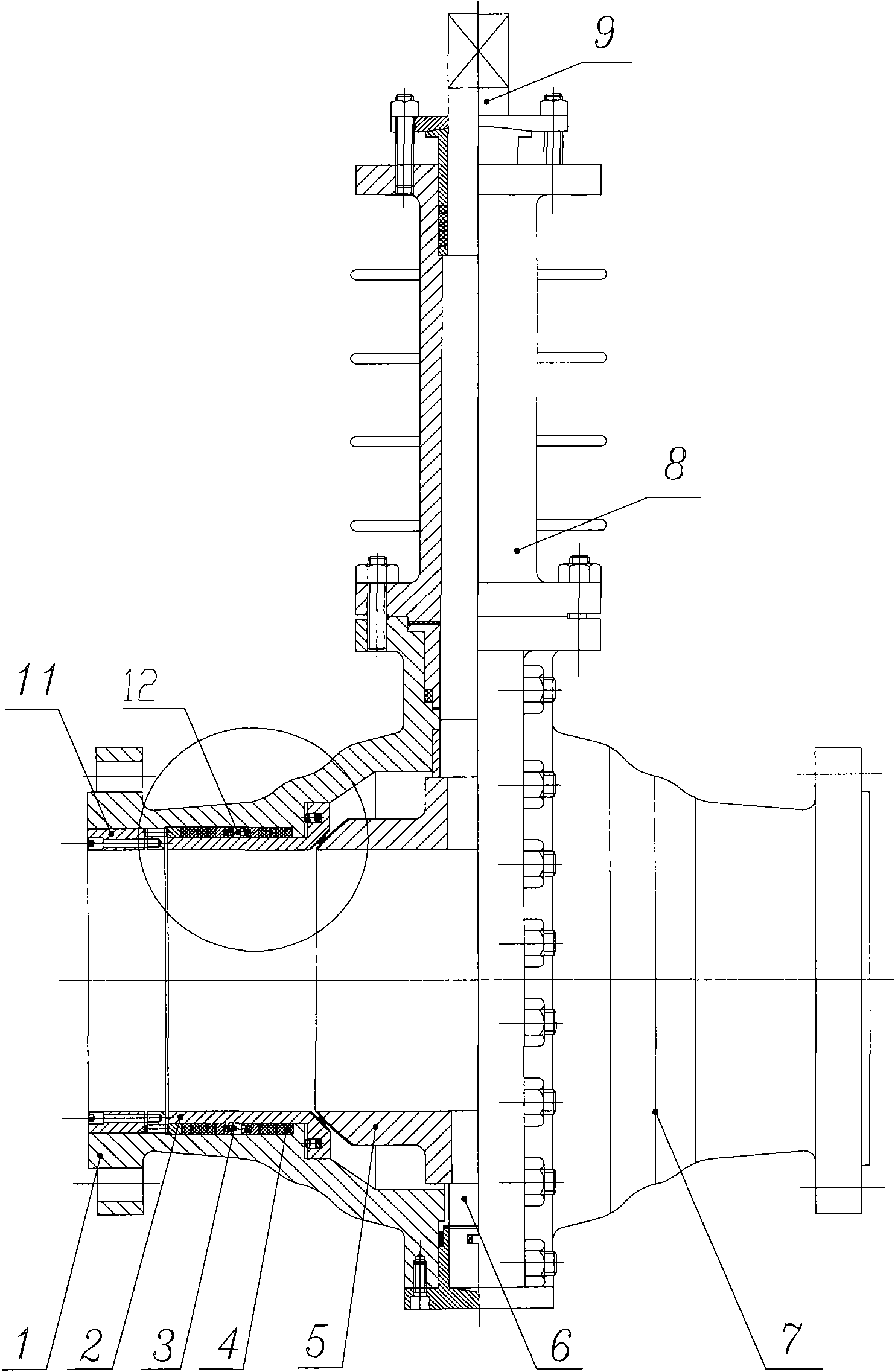

[0037] As shown in Figure 3 and Figure 4: the valve includes a left valve body (1), a right valve body (7), two floating valve seats (2), an auxiliary sealing spring (13), a ball (5), a shaft (9), shaft two (6), cooling body (8) and packing gland (11); the valve body adopts a two-body structure in which the left valve body (1) and the right valve body (7) are combined into one; and the upper shaft (6) and the lower shaft (9) are welded with the sphere (5) to form an integral structure; it is characterized in that a stuffing box is formed between the left valve body (1), the right valve body (7) and the floating valve seat (2) , and a built-in packing (4), and a high-temperature-resistant spring (3) is arranged between the packing (4), which constitutes a packing seal (12). Using the built-in high-temperature-resistant packing (4) and high-temperature-resistant spring (3) and the above-mentioned auxiliary The resilience of the sealing spring (13) makes the two floating valve se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com