Production technology for left valve barrel of colliery three-purposed hydraulic valve

A production process and hydraulic valve technology, which is applied in the production process field of the left valve cylinder of the coal mine three-purpose hydraulic valve, can solve the problems of increased production cost, low production efficiency, waste of raw materials, etc., to save steel, improve production efficiency, save The effect of social resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 (Taking the left valve barrel of the DZF coal mine three-purpose hydraulic valve as an example)

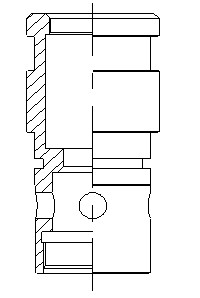

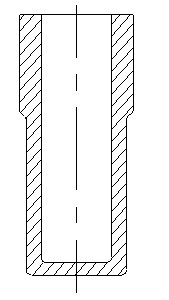

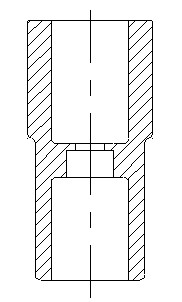

[0036] Purchase round steel with a diameter of 45mm; blank 1.35KG; heat to 1120-1200°C with a 250kw medium-frequency induction furnace; thickly remove scale on a 63-ton punch, and make a billet; put it on a 250-ton punch for high-temperature back extrusion, high temperature back extrusion forging see figure 2 ;Punch off the high-temperature reverse-extrusion forging with skin on a 63-ton punch press; then put it on a 160-ton high-speed hydraulic press for closed-type forging, see closed-type forging forging image 3 ;The temperature of the forging is measured by an infrared thermometer. If it is higher than 750°C, it is quenched and cooled by spraying water mist with high-pressure air on the quenching line. When it is cooled to 300-400°C, stop spraying water mist for cooling. After cooling to room temperature, the forging is Heating in well-type tempering fu...

Embodiment 2

[0037] Embodiment 2 (Take the left valve barrel of the DZF coal mine three-purpose hydraulic valve as an example)

[0038] Purchasing round steel with a diameter of 45mm; blanking 1.4KG; heating to 1120-1200°C with a gas furnace; rough descaling, billet making, and high-temperature reverse extrusion on the FP-400 CNC electric screw press; on a 63-ton punching machine Wash away the back-extruded joint skin; put it on a 200-ton punch press for closed-type forging again; measure the temperature of the forgings with an infrared thermometer, and quench and cool them with oil if the temperature is higher than 750 ° C. After cooling to room temperature, the forgings are returned in the well Furnace at 500-540°C, heat preservation for 1-1.5 hours and tempering; CNC lathe finishing turning, milling machine processing, fitter and other processes.

Embodiment 3

[0039] Embodiment 3 (Taking the left valve cylinder of the DZF coal mine three-purpose hydraulic valve as an example)

[0040] Purchase round steel with a diameter of 45mm; blank 1.35KG; use a 250kw medium frequency induction furnace to heat to 1120-1200°C; pier rough descaling on a 63-ton punching machine and make a billet; put it on a 250-ton fast hydraulic press for high-temperature reverse extrusion; Punch off the joint skin of the reverse extrusion forging on the 63-ton punching machine; put it on the 160-ton fast hydraulic press for closed forging again; wash off the internal skin on the 63-ton punching machine; forgings are treated with high-pressure air-cooling and heat treatment; Fitters and other processes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com