Heavy-calibre ball valve

A large-diameter, ball valve technology, applied in valve details, valve device, valve shell structure, etc., can solve problems such as valve seal failure, easy erosion damage, and inability to work normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

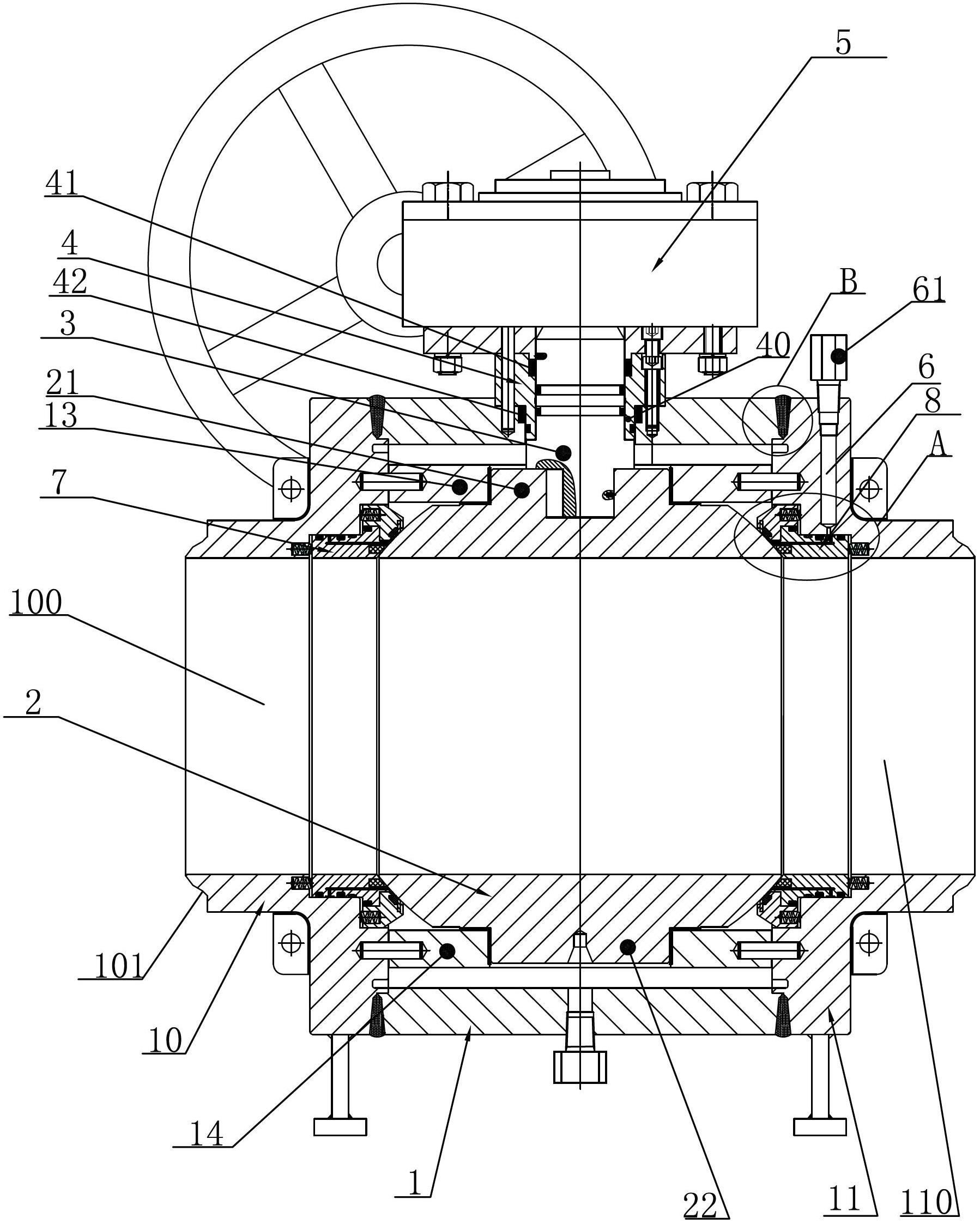

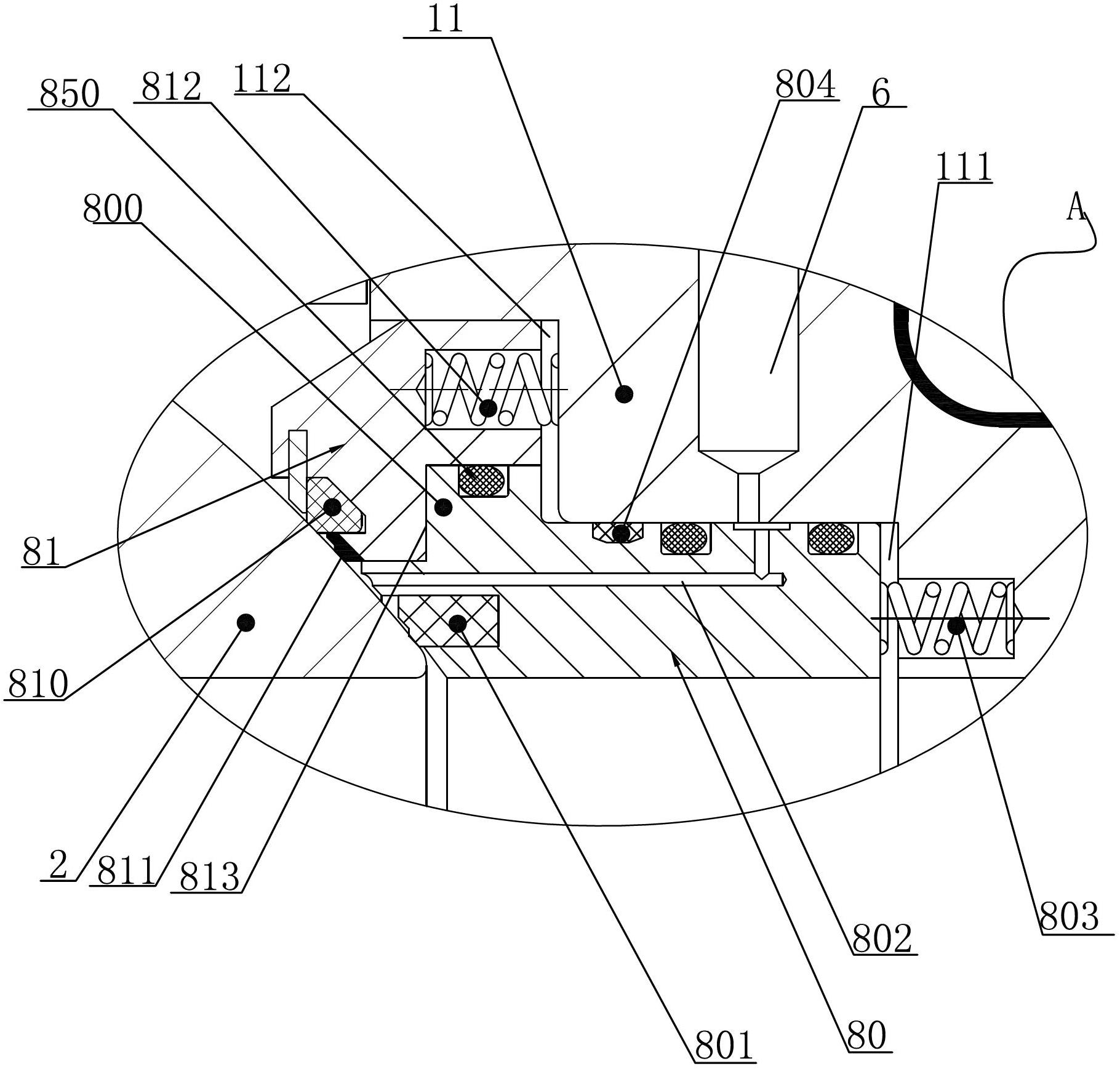

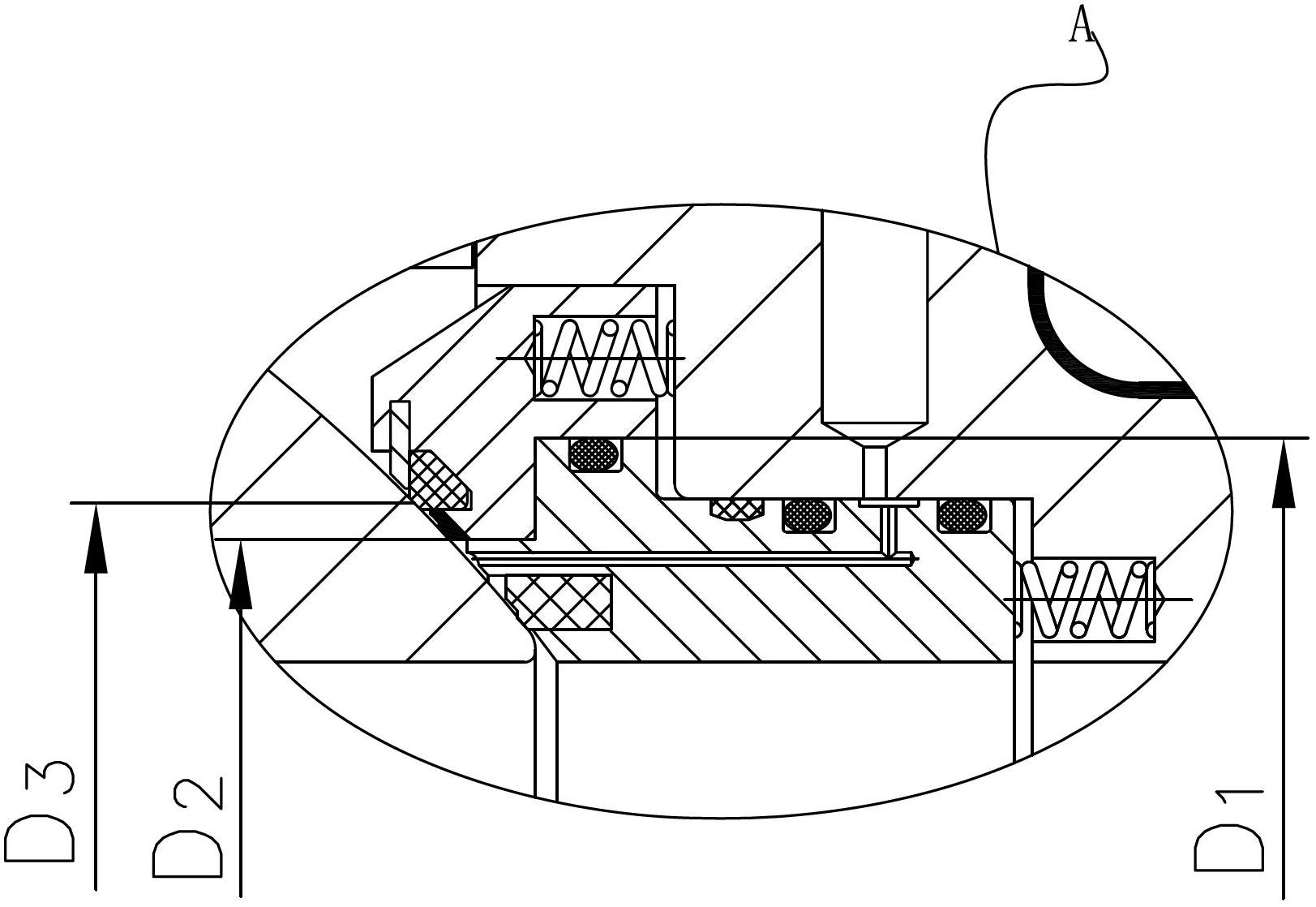

[0029] Such as Figure 1-3 As shown, a large-diameter ball valve disclosed in the present invention includes a valve body, and the valve body includes a main valve body 1 provided with a valve cavity, a left valve body 10 provided with an inflow channel 100 and a valve body provided with an outflow channel 110 The right valve body 11; the left and right valve bodies 10, 11 are welded on both axial sides of the main valve body 1 to form a welded combined valve body, forming a valve cavity connected to the inflow channel 100 and the outflow channel 101; the main valve body 1 and the left and right The welding of the valve body 10, 11 is a narrow gap double V-shaped groove weld 9 welding (such as image 3 shown), can greatly reduce the welding groove cross-sectional area and weld metal filling amount and improve efficiency; the left and right valve bodies 10, 11 are provided with The welding groove 101 for valve welding on the pipeline (the welding groove 101 in this specific em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com