Electrical feedback large-scale servo hydraulic cylinder driven by double motors

A dual-motor-driven, servo-hydraulic cylinder technology, used in servo motor components, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of inability to accurately control hydraulic cylinders, insufficient speed control, and complicated use, and achieve easy quantitative control. , The effect of uniform internal force and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

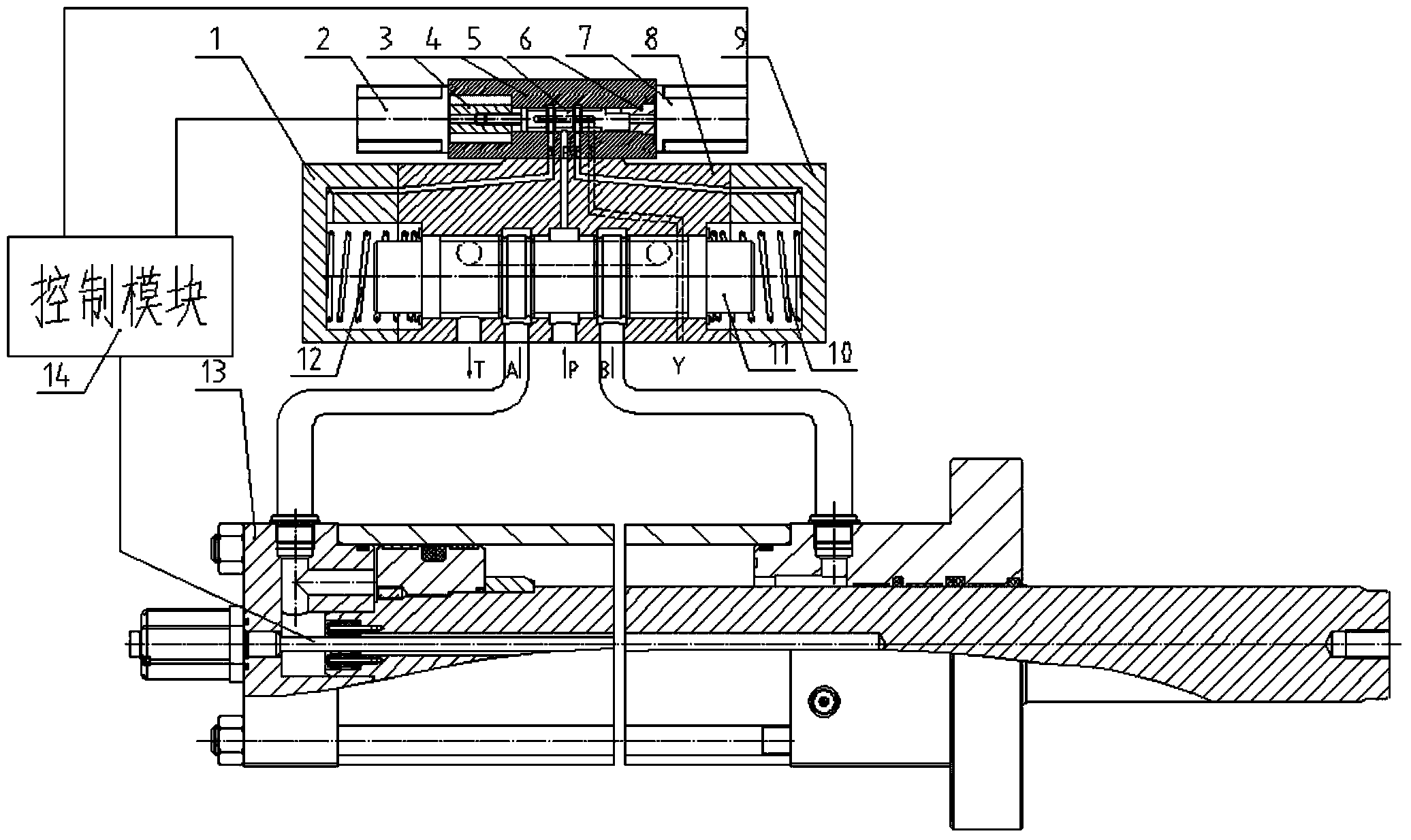

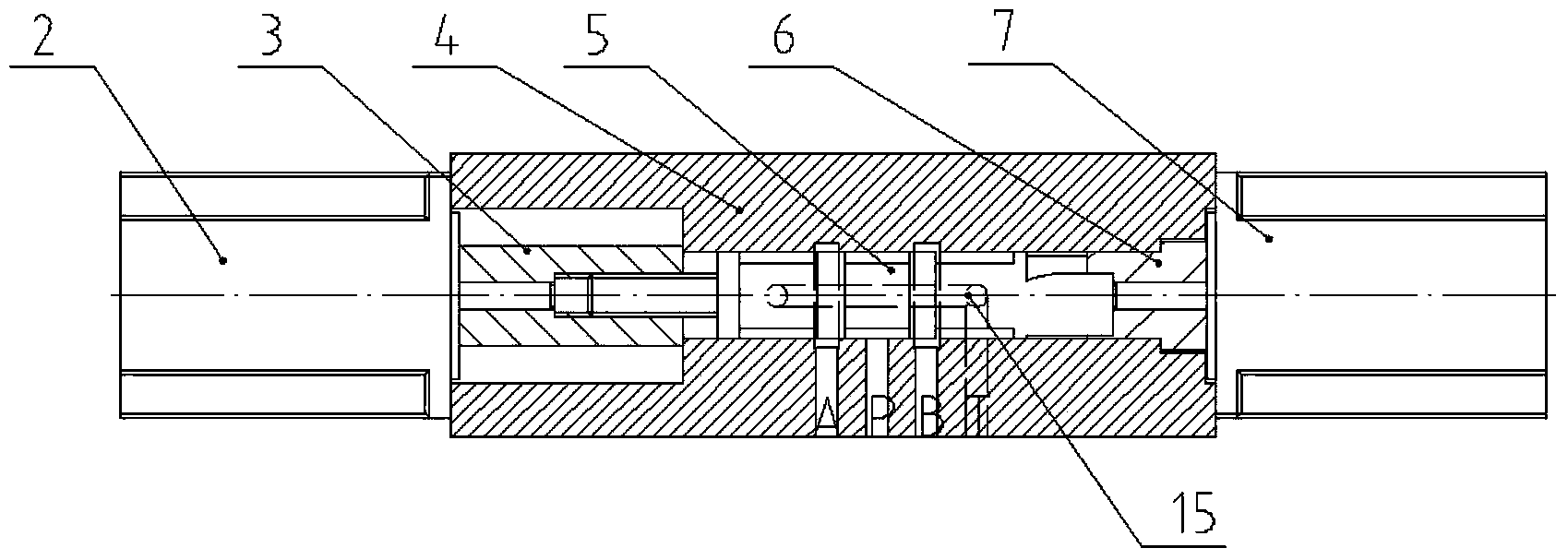

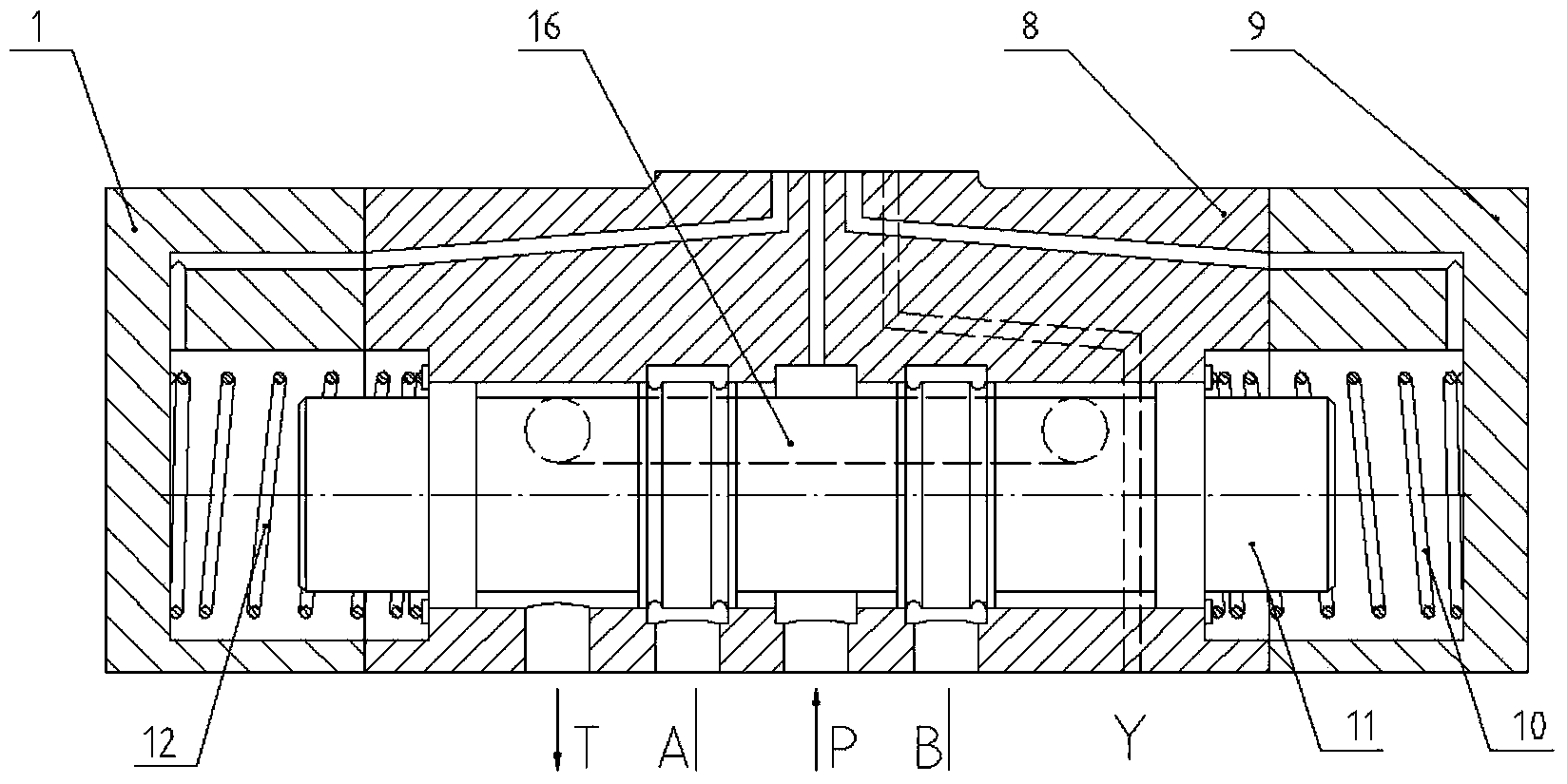

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0012] refer to Figure 1 ~ Figure 4 , the electric feedback large-scale servo hydraulic cylinder driven by dual motors of the present invention includes a hydraulic cylinder, and it also includes a pilot valve and a slide valve, and the pilot valve includes a pilot valve body 4, and the pilot valve body 4 A pilot valve spool 5 is installed inside, and four pilot valve bosses are arranged on the pilot valve spool 5. The left chamber of the pilot valve is formed between the two pilot valve bosses on the left side, and the two pilot valve bosses on the right side The right cavity of the pilot valve is formed between the platforms, and the first oil port A of the pilot valve, the second oil port P of the pilot valve, the third oil port B of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com