Fast valve specially for fire flighting

A fast and fire-fighting technology, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of long closing time, troublesome opening, valve submersion, etc., and achieve the effect of fast operation and shortened operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

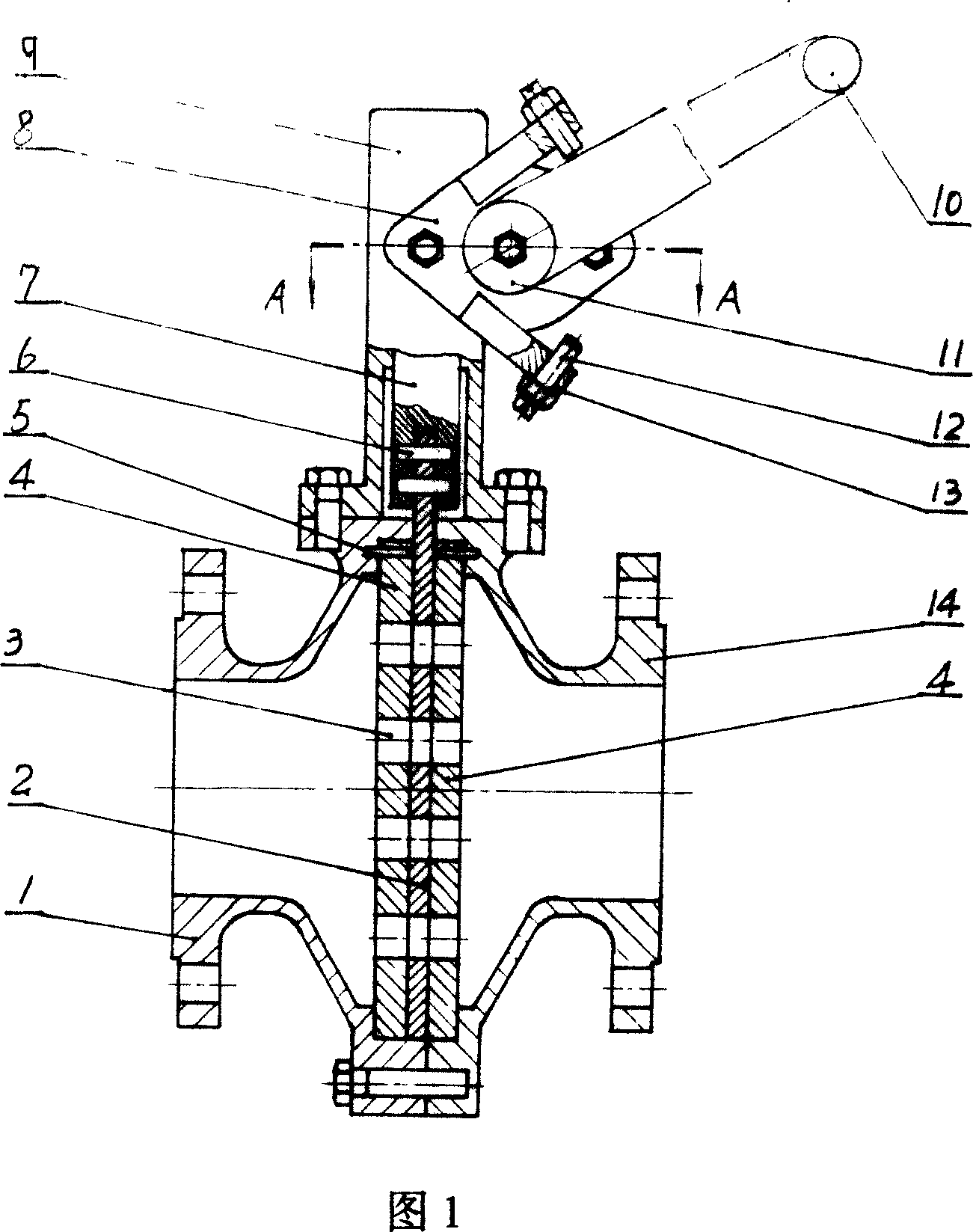

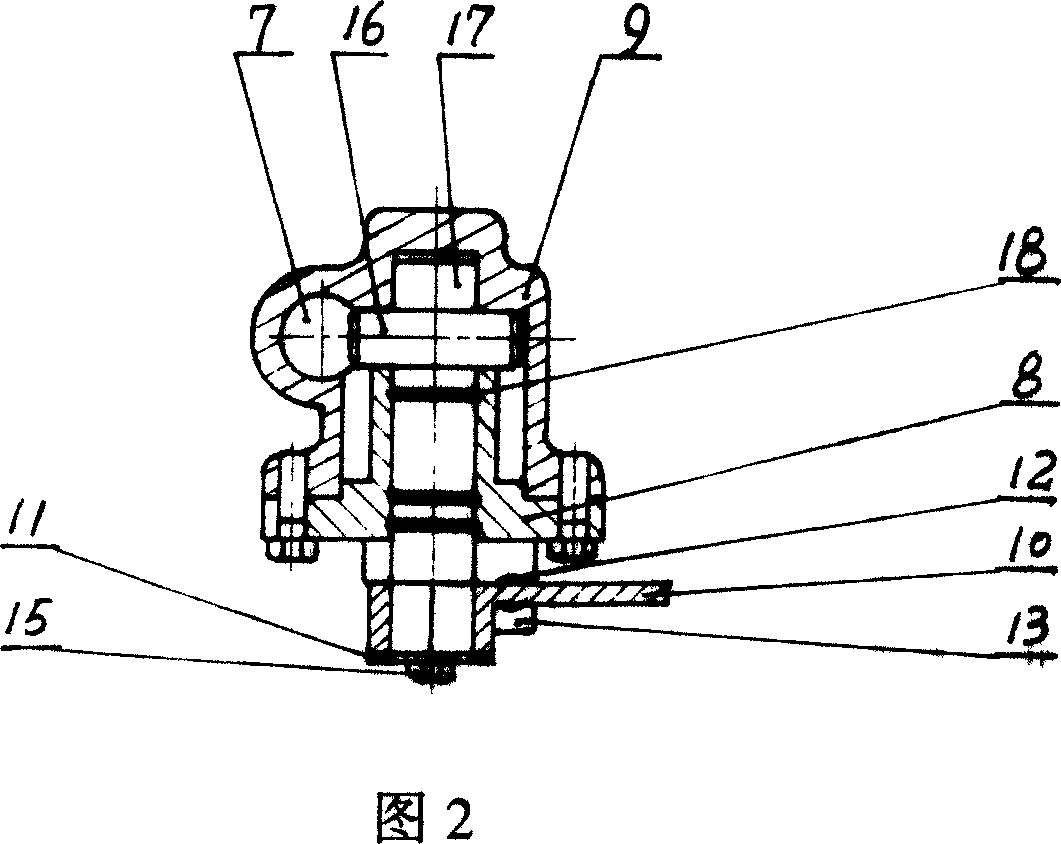

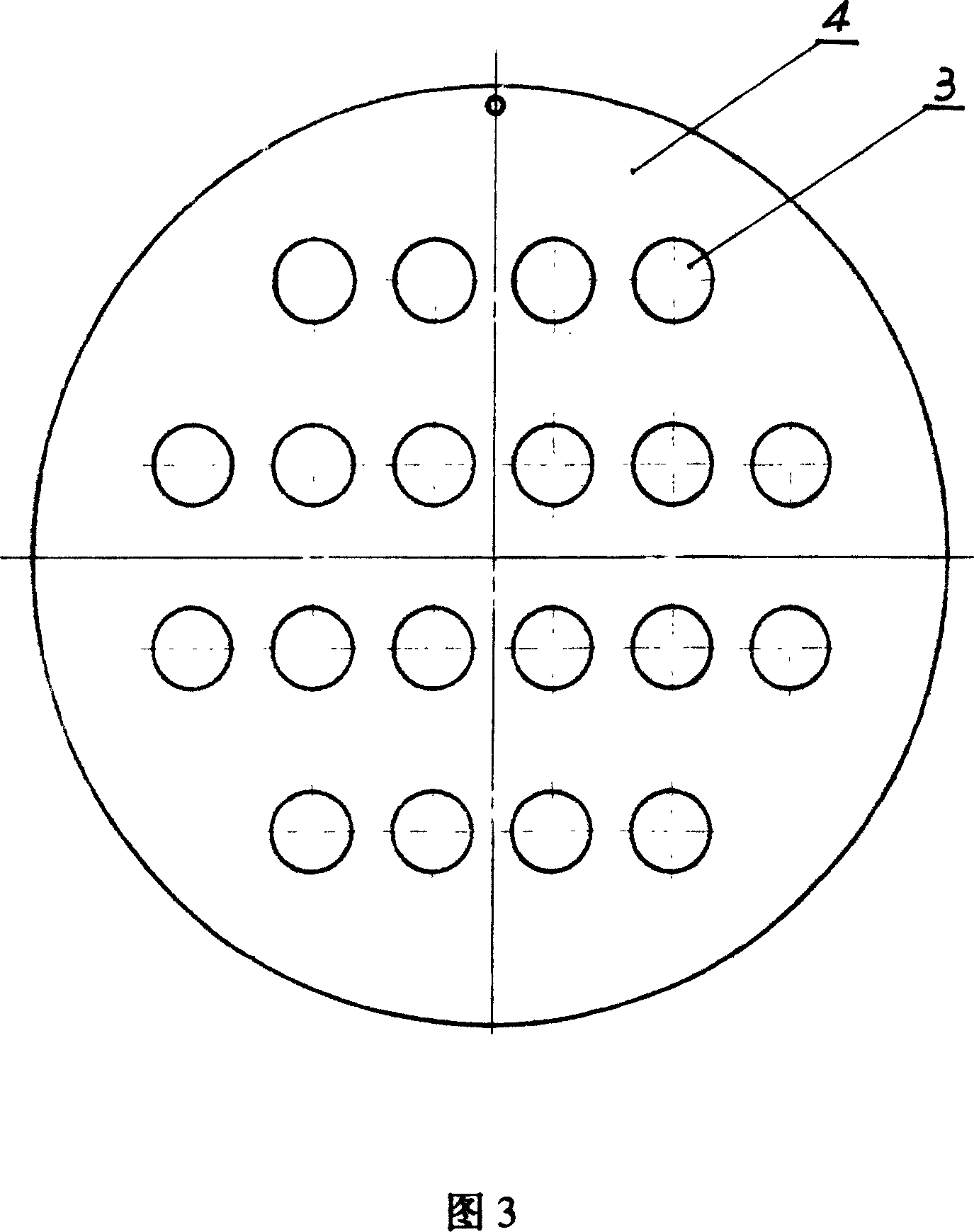

[0017] The fire-fighting fast valve includes a left valve body 1, a right valve body 14, a valve seat 4 arranged in the valve body, a valve plate 2 matched with the valve seat and a handle 10 connected with the valve plate. In this embodiment, the valve seats 4 are two flat plates made of stainless steel, which are arranged radially symmetrically in the inner cavities of the left and right valve bodies respectively, and the two valve seats 4 are respectively fixed on the left and right sides by pins 5. on the valve body. The valve plate 2 is a flat plate made of stainless steel sandwiched between two valve seats, and the surfaces on both sides of the valve plate 2 are slidingly matched with the surfaces of the two valve seats 4 respectively. At least one through hole 3 corresponding to each other is respectively arranged on the valve seat 4 and the valve plate 2. In this embodiment, there are twenty through holes, and all the through holes are arranged regularly. Finally, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com