Safety level electric ball valve

An electric ball valve, safety-level technology, applied in valve details, valve device, valve housing structure, etc., can solve problems such as helium leakage, aggravated helium leakage, long-term operation, etc., to avoid leakage, meet external sealing requirements, meet long-term reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

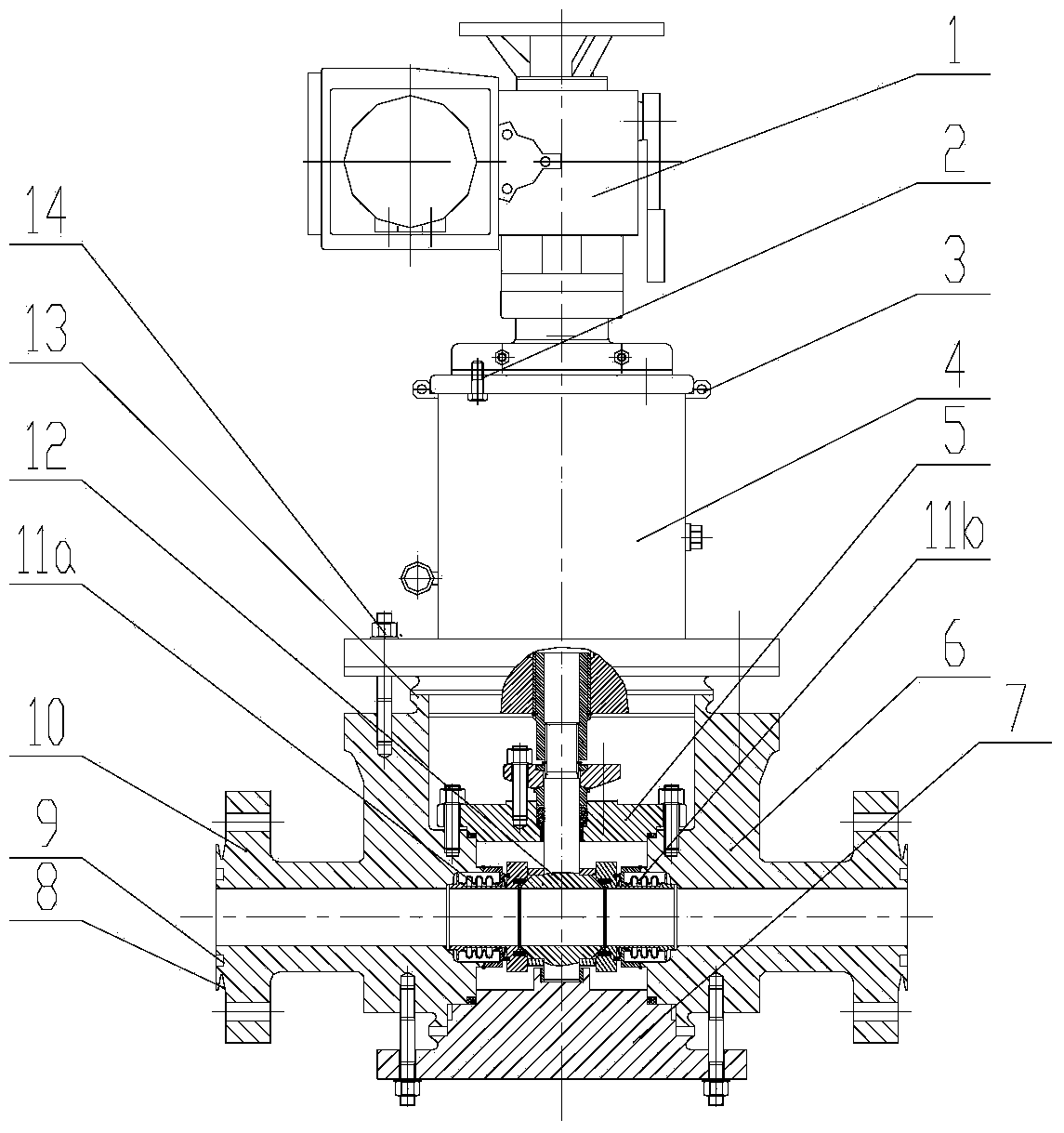

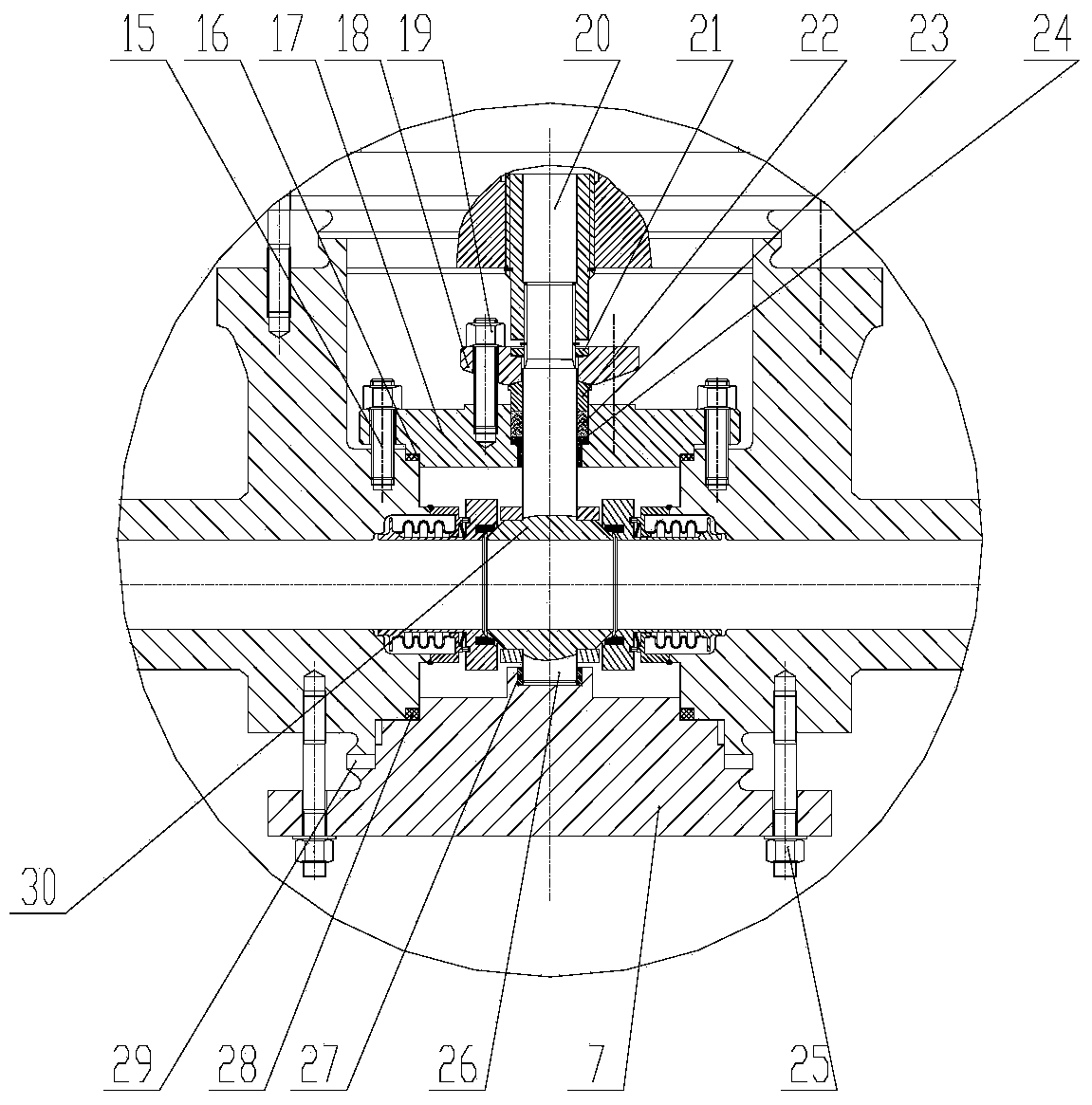

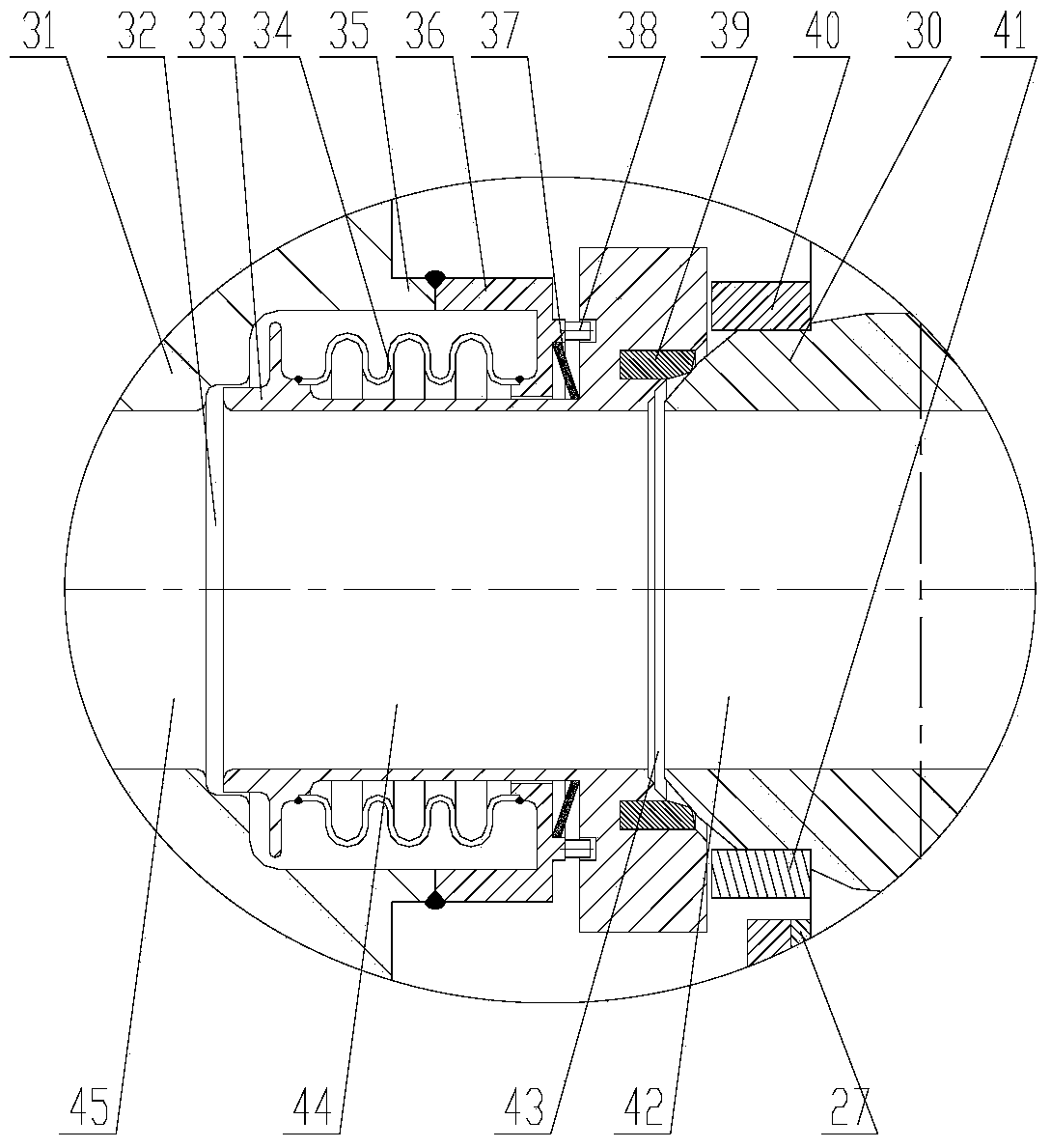

[0040] figure 1 It shows the front view of an embodiment of the pebble bed high temperature reactor safety grade electric ball valve involved in the present invention, figure 2 It is a partial view of the embodiment valve body and its internal structure, image 3 is a partial view of the implemented valve seat sealing structure, Figure 4 It is the position relationship diagram of the first cam and the sphere.

[0041] like Figure 1~3 As shown, the electric ball valve described in this embodiment is composed of a valve body 6, a left valve seat assembly 11a, a valve ball 12, a right valve seat assembly 11b, a blind flange 7, a magnetic drive 4 and an electric device 1. The valve ball 12 is composed of an upper va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com