66kv optically-controlled water-cooling thyristor valve box

A thyristor valve, thyristor technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems such as unfavorable repair and maintenance, circuit influence, etc., to achieve compact structure, reduce interference, and reduce the effect of parts types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

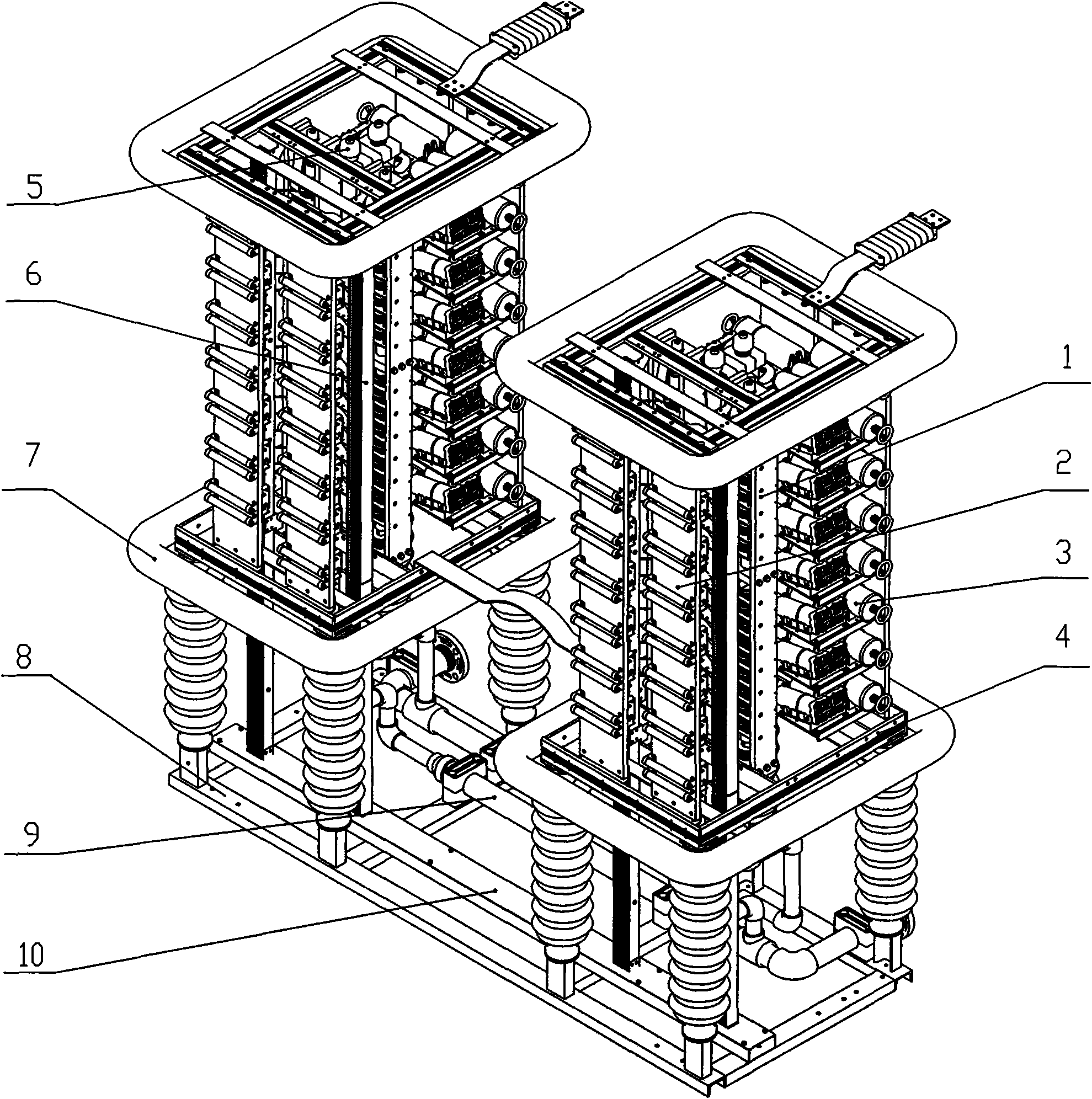

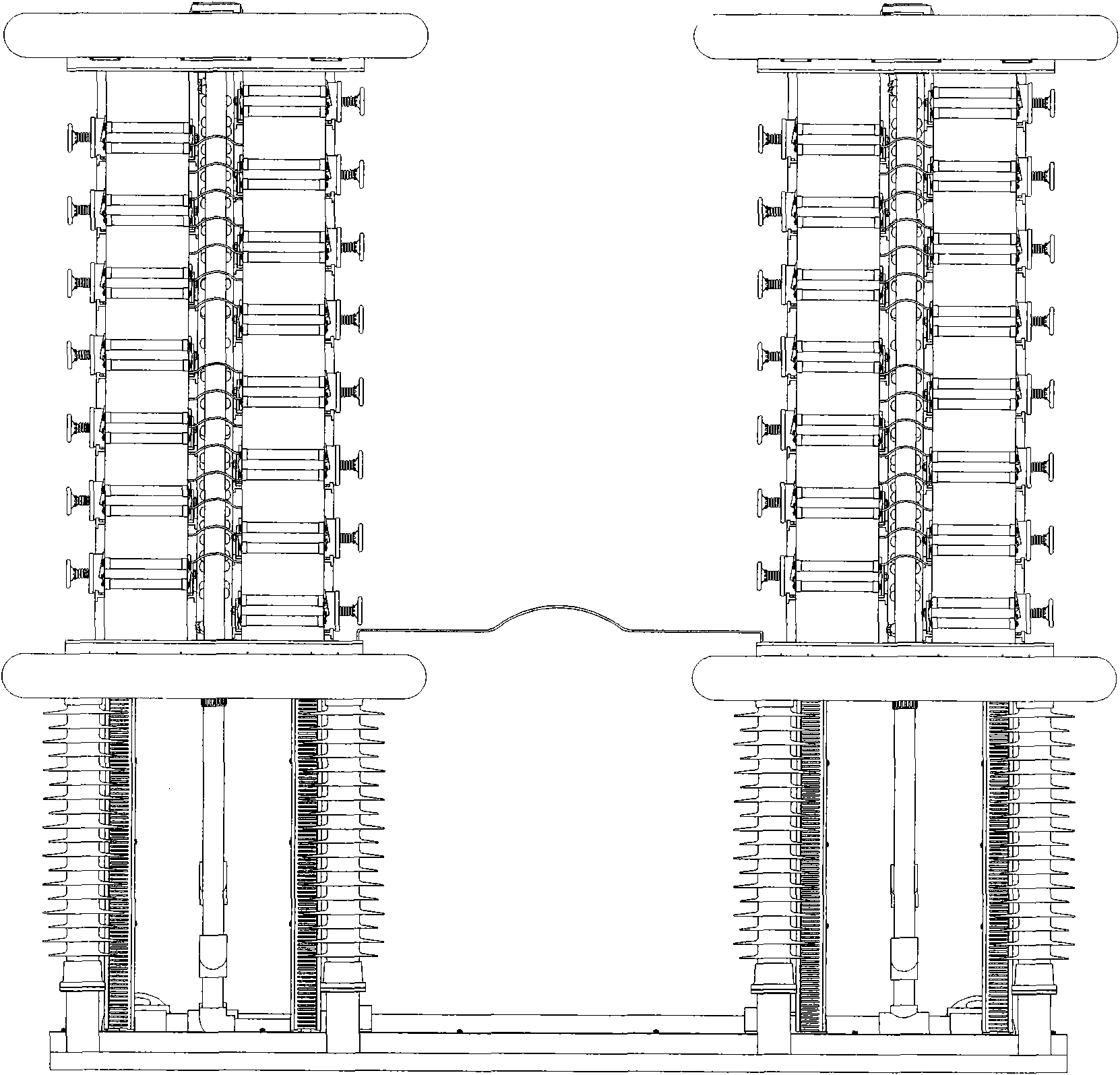

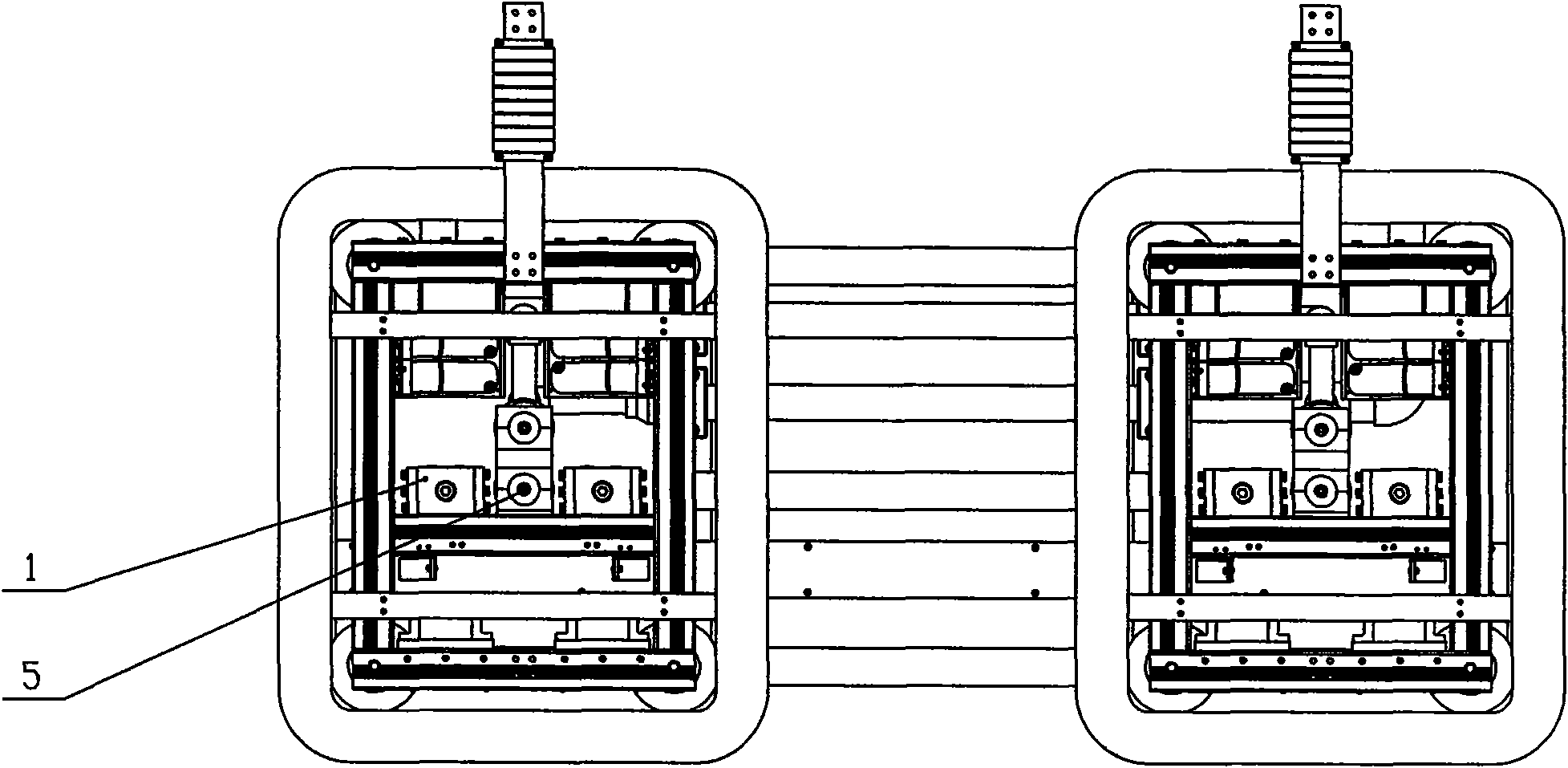

[0027] See Figure 1-Figure 5 , 66kV light-controlled water-cooled thyristor valve group, the valve group adopts a two-body vertical structure, consisting of two left and right valve units to form a single-phase valve group, and the left and right valve units are connected by copper foil soft row. Each valve unit is composed of a thyristor unit 1 , a return board unit 2 , a RC protection unit 3 , a frame unit 4 , an internal water pipe unit 5 , a wiring trough unit 6 , and a pressure equalizing ring unit 7 . The thyristor unit 1 that needs water cooling and the water-cooled resistors in the RC protection unit 3 are arranged on both sides of the internal water pipe unit 5, and are located in the middle of the valve unit; other components of the RC protection unit 3 that do not need water cooling except the water-cooled resistor , the return board unit 2, the wiring trough unit 6, and the pressure equalizing ring unit 7 are all located around the valve unit. Each unit is connec...

Embodiment 2

[0030] refer to figure 1 , 35kV light-controlled water-cooled thyristor valve group, the valve group adopts a single vertical structure, consisting of a thyristor unit 1, a return board unit 2, a resistance-capacitance protection unit 3, a frame unit 4, an internal water pipe unit 5, and a wiring trough unit 6 , The pressure equalizing ring unit 7 is composed. The thyristor unit 1 that needs water cooling and the water-cooling resistance in the resistance-capacity protection unit 3 are arranged on both sides of the internal water pipe unit 5, and are located in the middle of the valve unit; other components of the resistance-capacity protection unit 3 that do not need water cooling except for the water-cooled resistance, , the return plate unit 2, the wiring trough unit 6, and the pressure equalizing ring unit 7 are all located around the valve group. Each unit is connected with the frame unit 4 through the epoxy glass cloth board. The valve body is connected to the base 8 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com