Installation fixture of press-seat butterfly valve seat

A technology for installing fixtures and butterfly valves. It is applied in the direction of manufacturing tools and workpiece clamping devices. It can solve the problems of high labor intensity, increase production costs, and reduce production efficiency, so as to improve working conditions and environment, and avoid damage to valve seats. The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

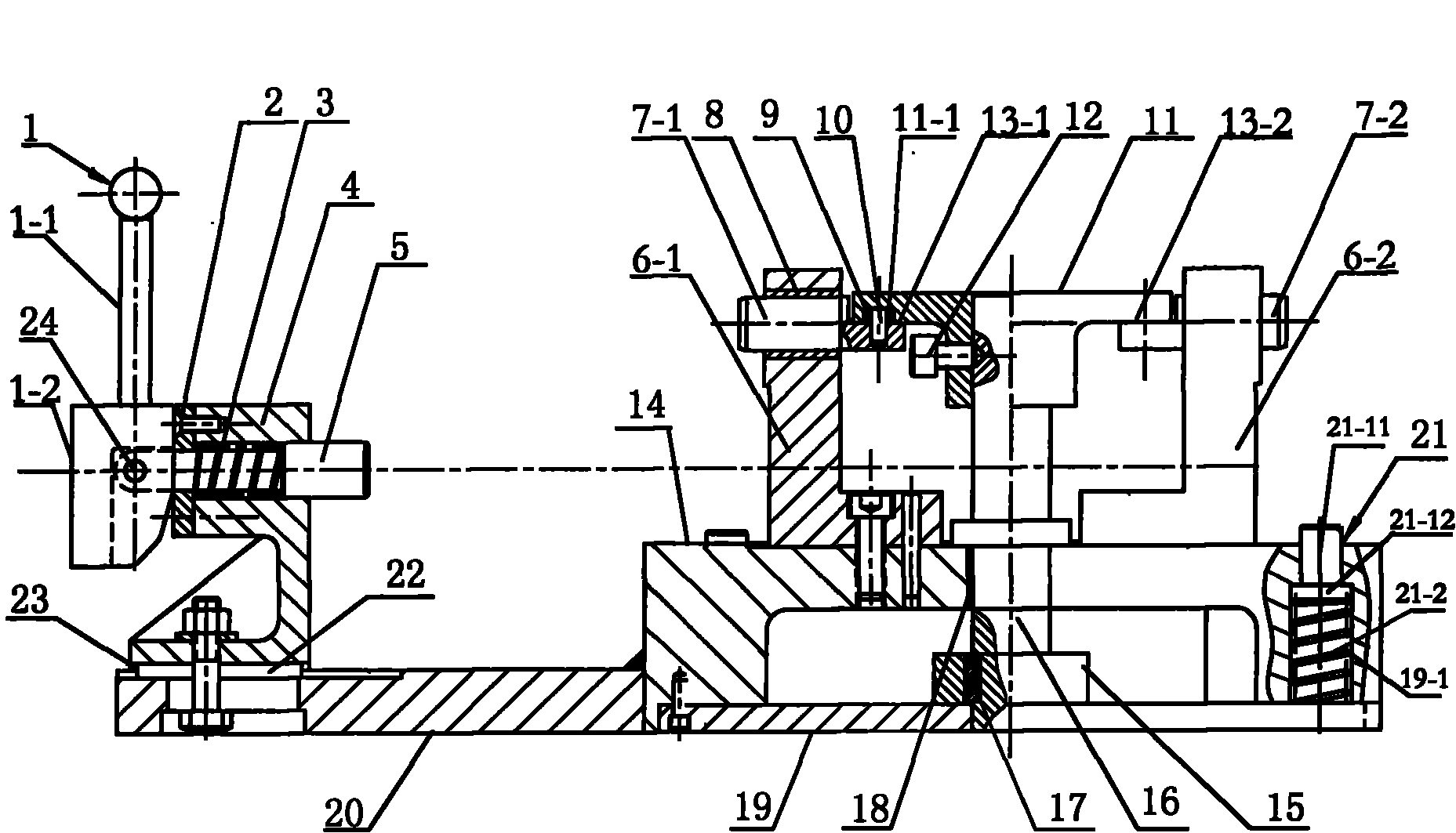

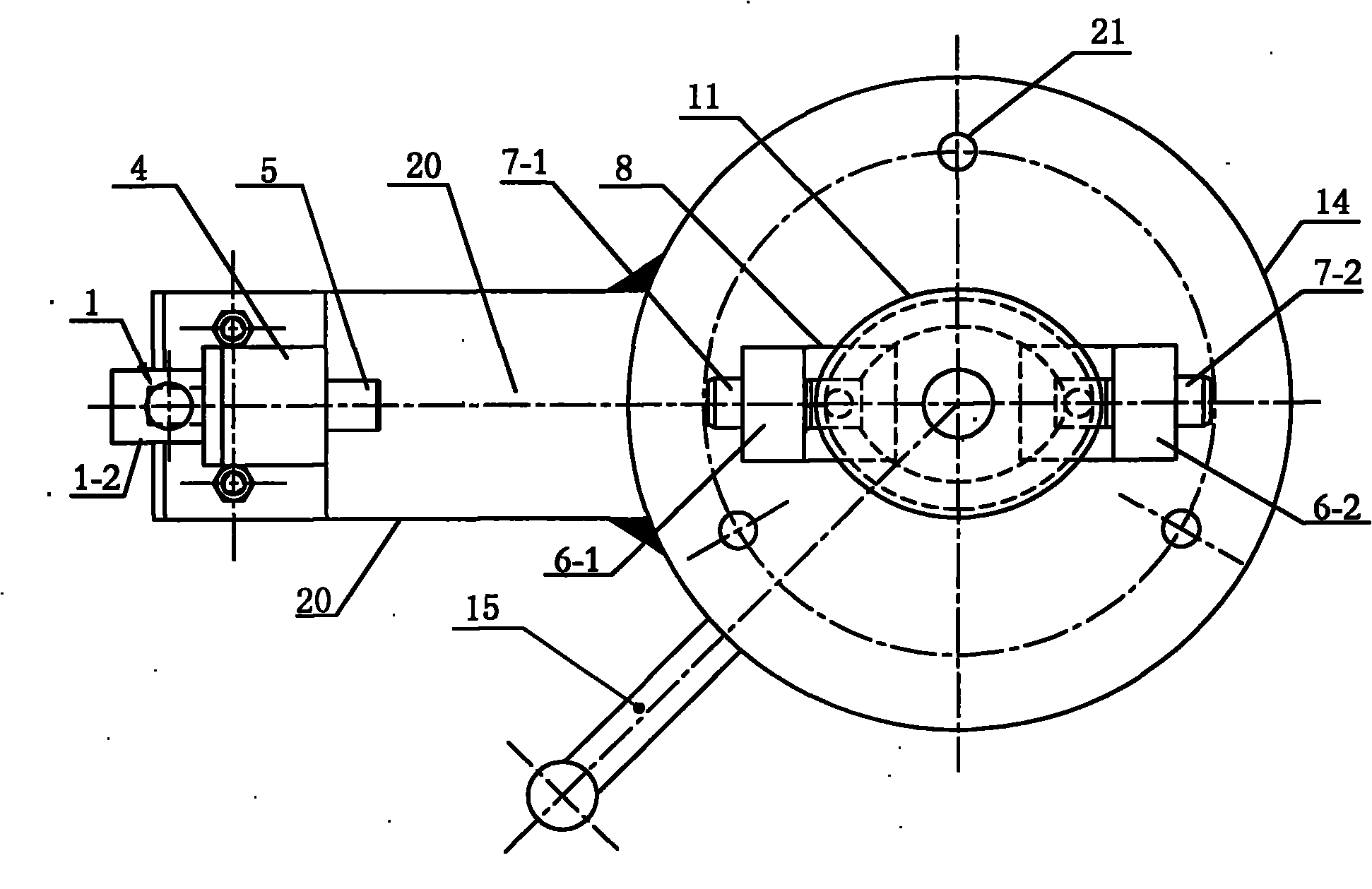

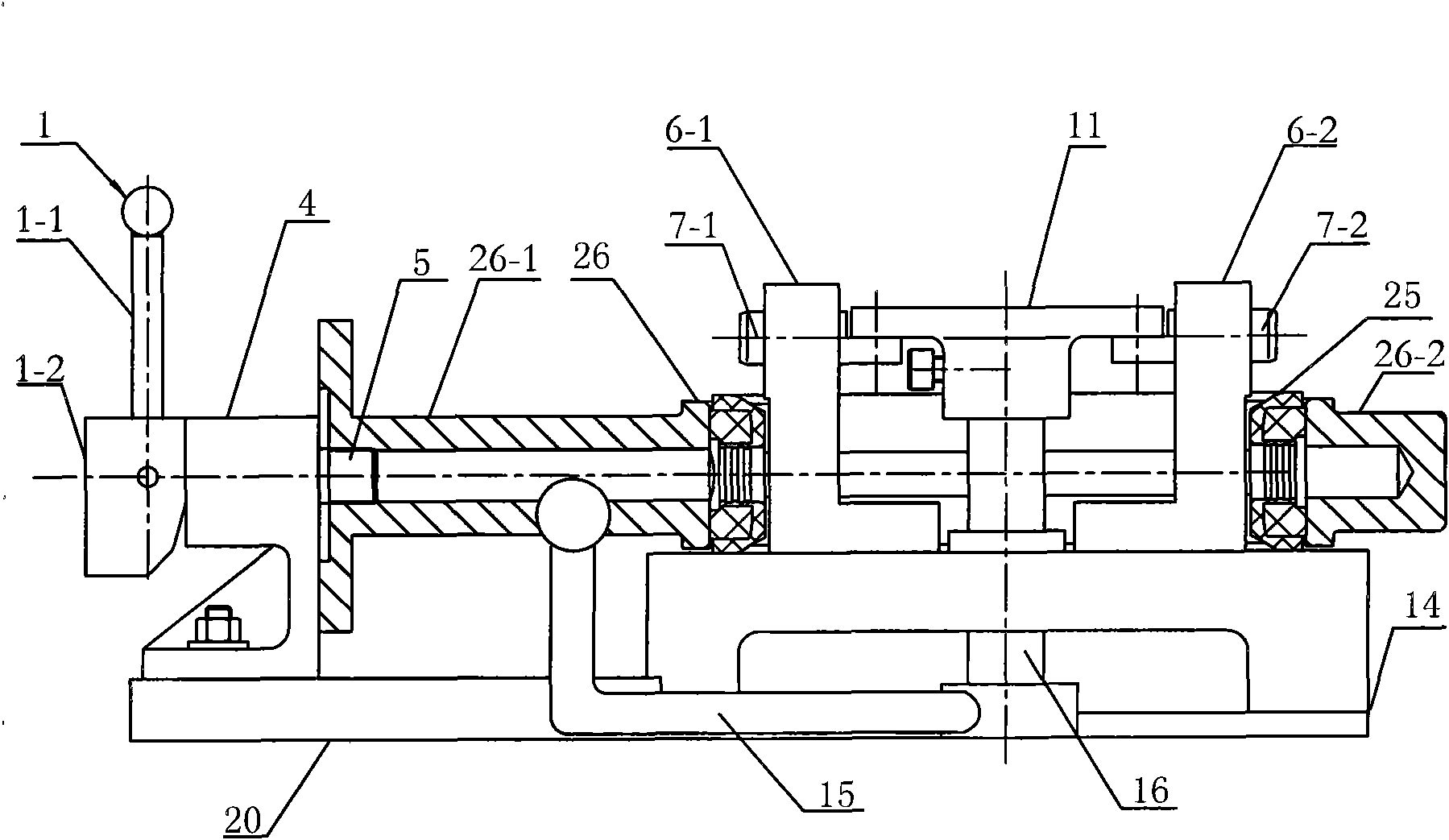

[0017] Figure 1 ~ Figure 4 It shows a seat mounting fixture for a press-seat butterfly valve and its specific application. The fixture is characterized in that it is mainly composed of a cylindrical pedestal 14 with a cavity for placing the valve body, and a bar-shaped seat 14 corresponding to the position and length of the upper valve neck. Support plate 20, shaft hole positioning pin 5 for inserting into the shaft hole of the upper valve neck, positioning pin handle 1 for pushing and pulling shaft hole positioning pin 5, support 4 with shaft hole positioning pin guide hole, for inserting valve seat shaft The left and right valve seat locating pins 7-1, 7-2 of the hole, the left and right brackets 6-1, 6-2, and the cam 11 respectively provided with the valve seat locating pin guide holes, and the return spring plays an elastic tensioning and reset function, camshaft 16 connected to the cam, cam turning handle 15 and three vertical elastic valve body positioning pins 21; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com