Gate valve

A technology of valve seat and valve plate, which is applied in the field of plug-in valves, can solve the problems of short service life, poor sealing effect, and uneven sealing force on both sides of the valve, and achieve the advantages of prolonging service life, improving sealing reliability, and improving standardization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

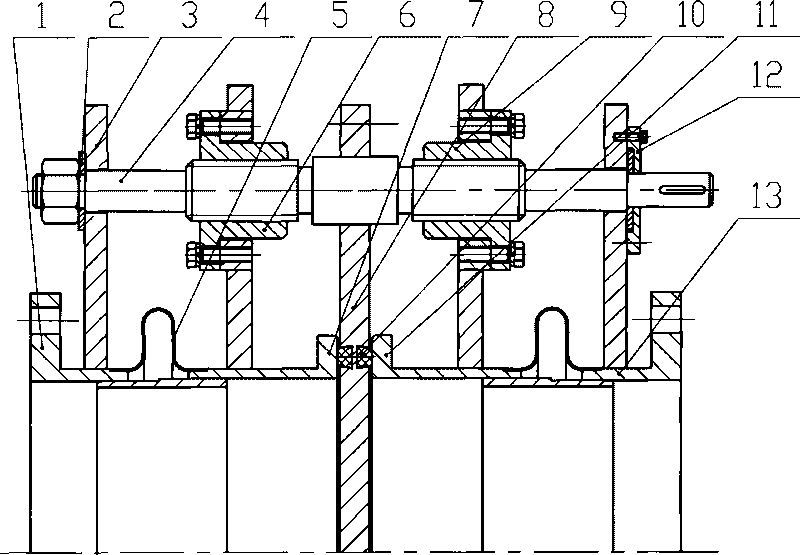

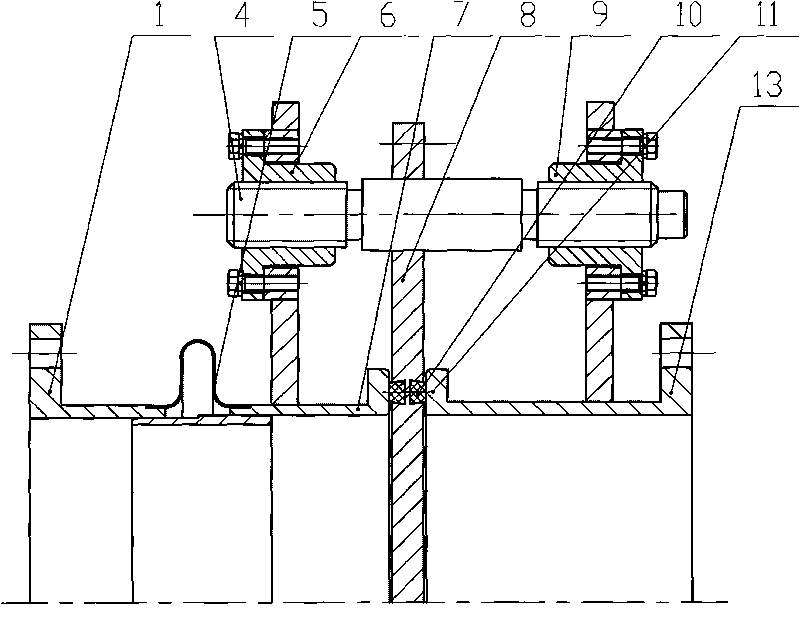

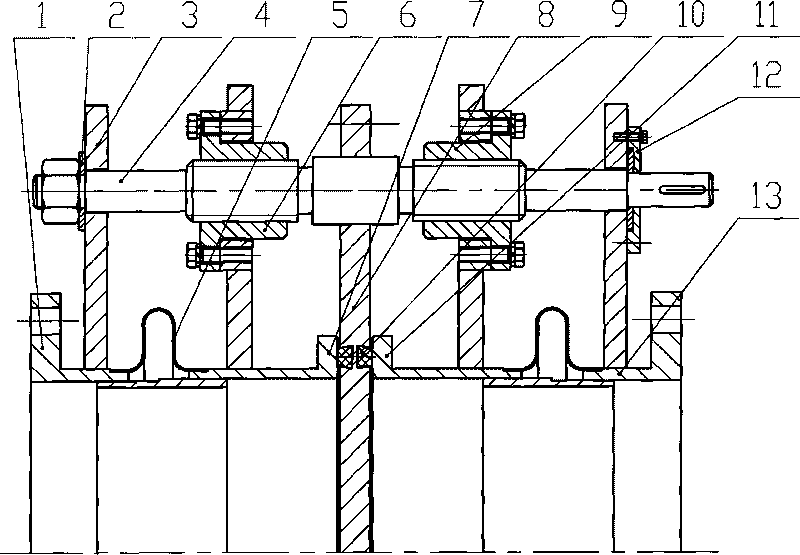

[0010] like figure 1 As shown, a flapper valve includes a left valve body 1, a bellows 5, a valve plate 8, a sealing ring 10, a screw rod 4, a left nut 6, a right nut 9, a right valve body 13, a left valve seat 7, a right The valve seat 11, the bellows 5 is welded between the left valve seat 7 and the left valve body 1, the sealing ring 10 is installed in the groove of the valve plate 8, the valve plate 8 is fixed in the middle of the screw rod 4, and the left end of the screw rod 4 passes through The left nut 6 is installed on the left valve seat 7, the right end of the screw rod 4 is installed on the right valve seat 11 through the right nut 9, and a bellows 5 is also welded between the right valve seat 11 and the right valve body 13; A support plate 3 is installed on the top, and the screw rod 4 passes through the support plate 3 and is fixedly connected with the left valve body 1 through the limit plate 2. The right valve body 13 is equipped with a support plate 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com