Abrasion-proof disk valve

A disc valve and valve stem technology, used in sliding valves, valve details, valve devices, etc., can solve the problems that general valves cannot meet the requirements, the seals cannot be opened and closed normally, and the normal use of the valve is affected, and the flow resistance is small. , fast speed, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

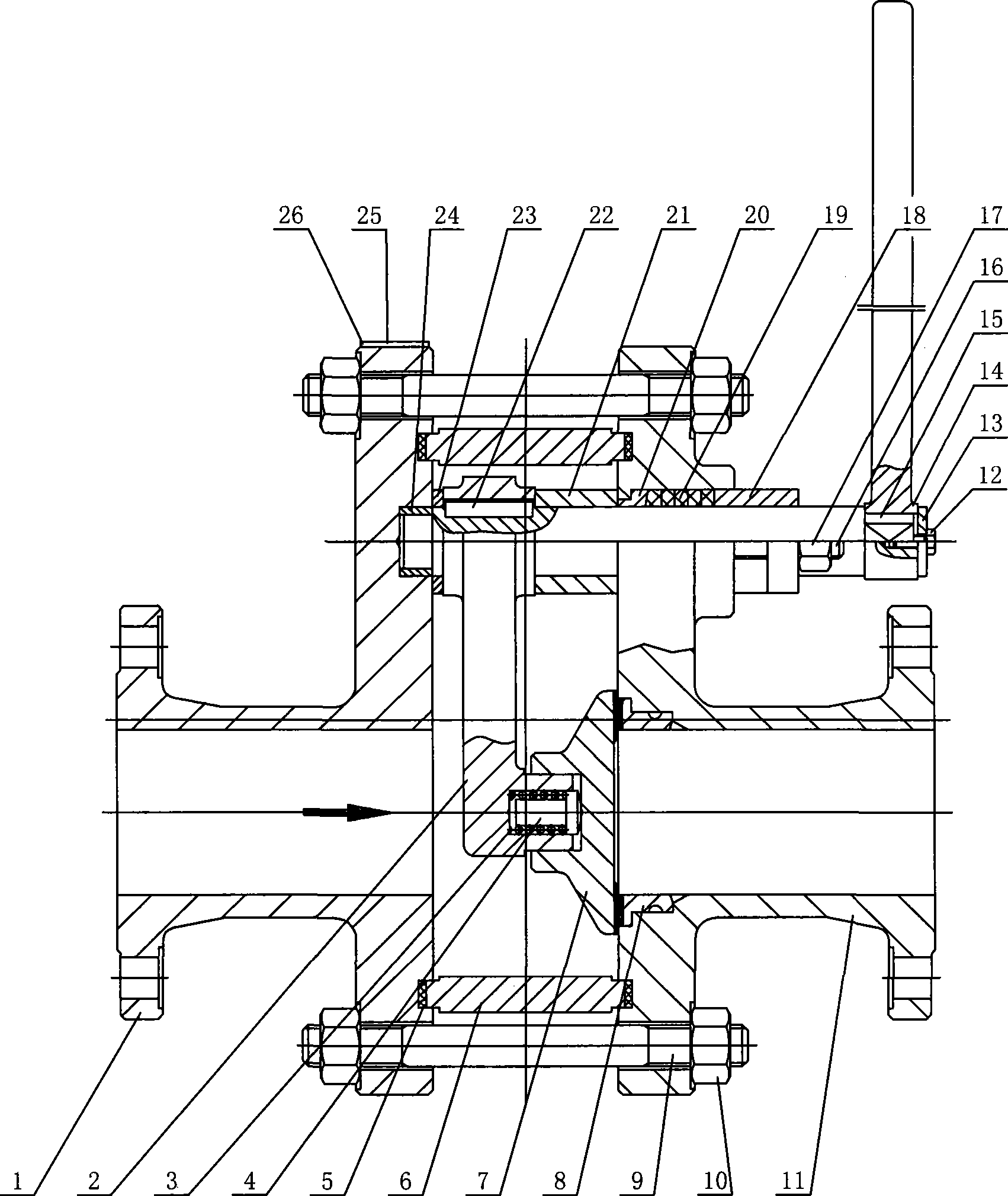

[0013] Such as figure 1 As shown, it includes left valve body 1, rocker arm 2, spring 3, top core 4, sealing gasket 5, valve body 6, valve disc 7, valve seat 8, stud 9, nut 10, right valve body 11, screws 12. Washer 13, handle 14, valve stem 15, stud 16, nut 17, packing gland 18, packing 19, packing pad 20, adjusting bushing 21, key 22, adjusting gasket 23, bushing 24, nail 25 , Nameplate 26.

[0014] The present invention adopts the valve stem 15 to be installed in the valve body 6, the valve stem 15 is equipped with an adjusting sleeve 21, the valve stem 15 is inserted into the stuffing box of the right valve body 11, and the valve seat 8 is welded on the right valve body 11, and the valve stem 15 Install key 22, rocker arm 2, adjusting gasket 23, bearing 21 according to this, load onto spring 3, top core 4, valve clack 7 on rocker arm 2, put into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com