Numerical control spherical pair grinder and grinding method

A secondary grinding machine and grinding method technology, which is applied in the direction of grinding machine tools, grinding devices, working carriers, etc., can solve the problems of large power consumption, large volume, environmental pollution, etc., improve the accuracy of grinding shape, improve the degree of automation, and get rid of physical strength effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

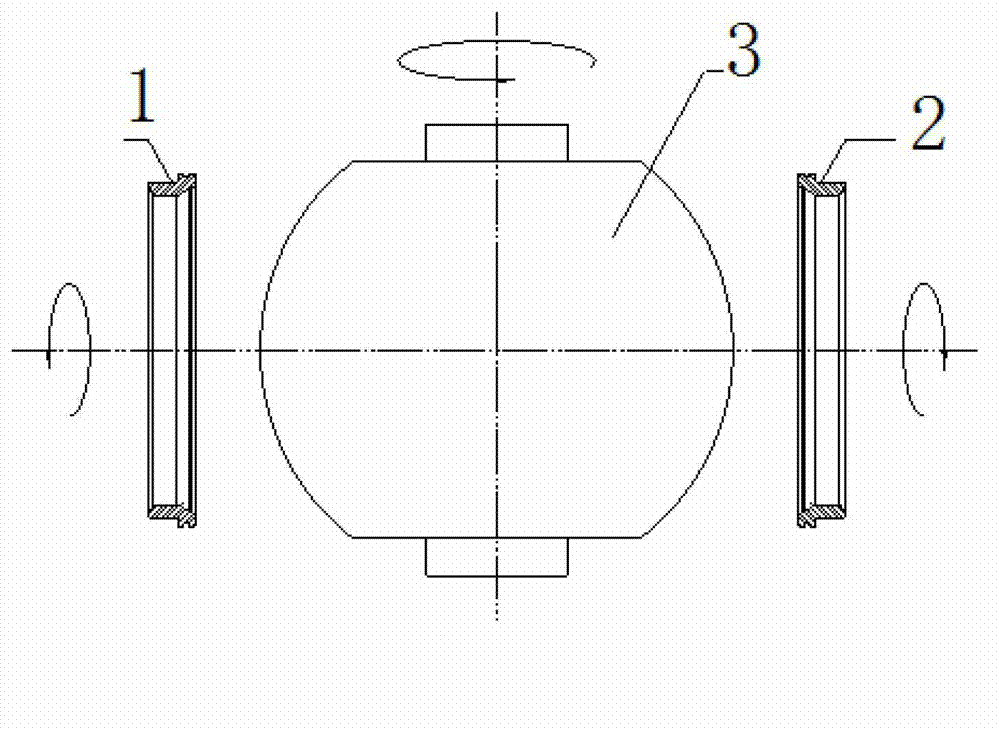

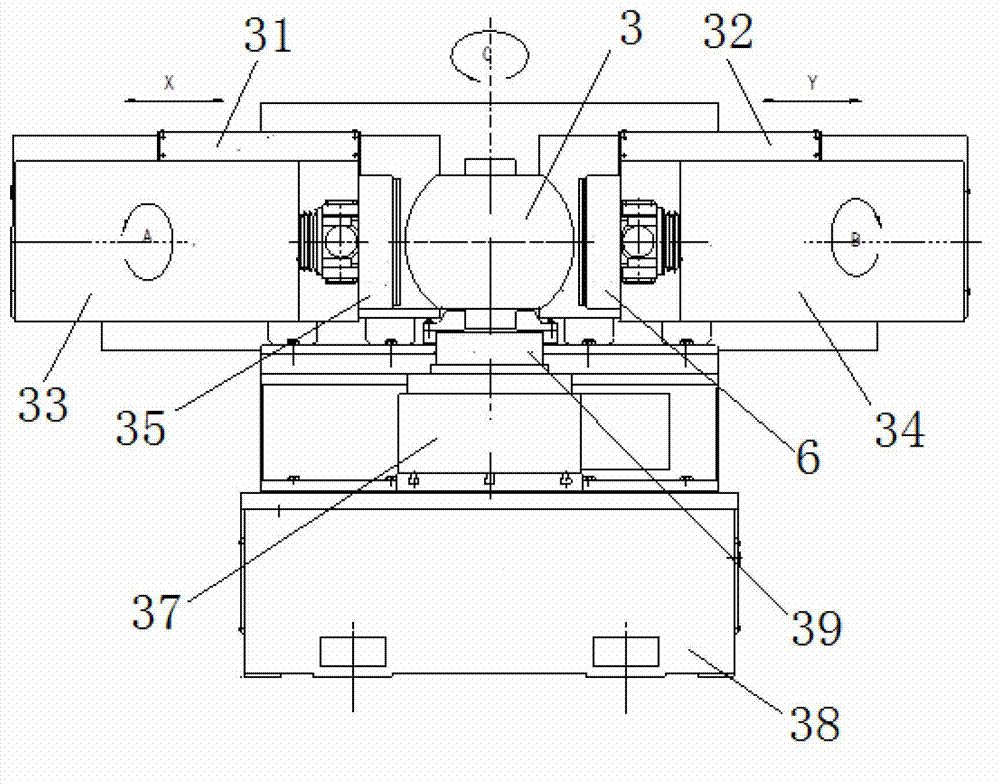

[0034] Embodiment 1: as Figure 1-Figure 4 As shown, CNC turntable 37, bed 38, ball fixture 39, left CNC slide plate 31, left valve seat spindle box 33, left valve seat fixture 35, right CNC slide plate 32, right valve seat spindle box 34, right valve seat fixture 6 ;

[0035] The bed 38 is connected to the CNC turntable 37, the left CNC slide 31 and the right CNC slide 32;

[0036] CNC turntable 37 is connected with sphere fixture 39;

[0037] The left numerical control slide plate 31 is connected with the left valve seat spindle box 33; the left valve seat spindle box 33 is connected with the left valve seat clamp 35;

[0038] The right numerical control slide plate 32 is connected to the right valve seat spindle box 34; the right valve seat spindle box 34 is connected to the right valve seat clamp 6;

[0039] The processed sphere 3 is connected with a sphere fixture 39;

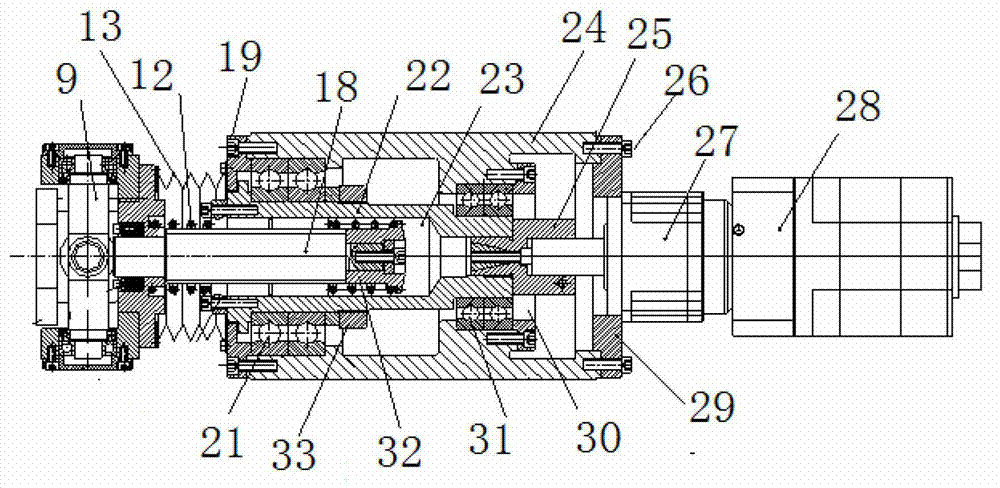

[0040] The structure of the left valve seat spindle box 33 and the right valve seat spindle box 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com