Plastic faucet body and manufacturing die thereof

A faucet and plastic technology, applied in the field of machinery, can solve the problems of reduced water tightness of the faucet body, leakage of the joint surface of secondary injection molding, and inability to apply to mass production, etc., and achieves good sealing, reduces assembly components, and prevents leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

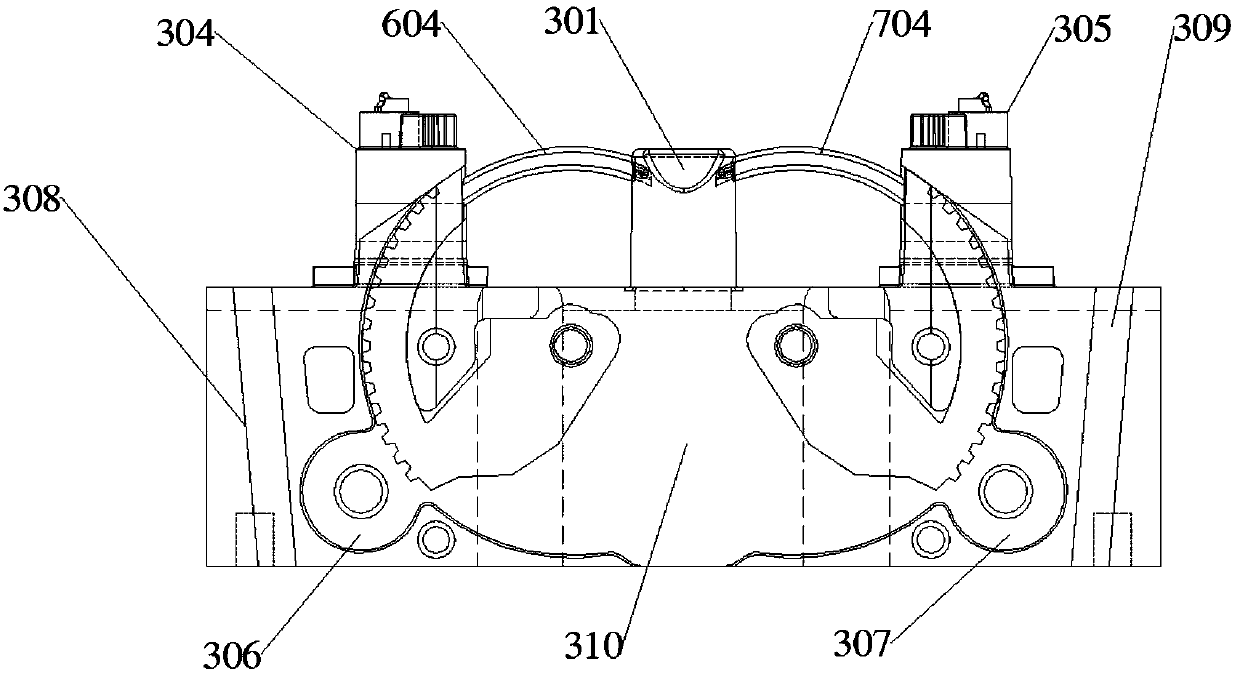

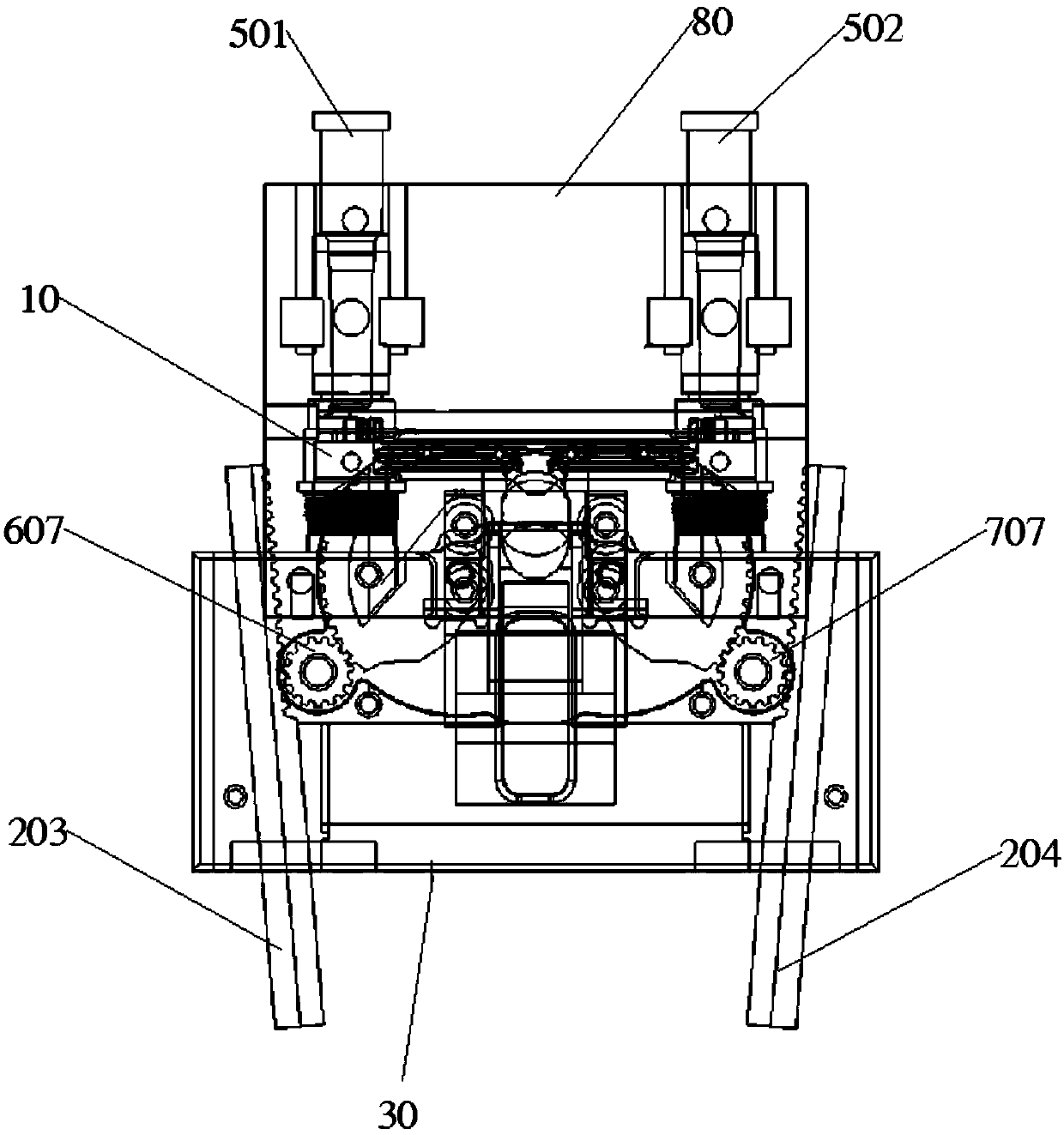

[0041] A mold for manufacturing a plastic faucet body, comprising a mold base, an upper mold 80, the upper mold 80 is provided with a left water inlet core cavity and a right water inlet core cavity, and a detachable left water inlet core cavity is set inside the left water inlet core cavity. The water inlet mold core 501, the right water inlet mold core cavity is provided with a detachable right water inlet mold core 502, and also includes a fixed mold 30, a left water inlet core-pulling mechanism and a right water inlet core-pulling mechanism, the fixed mold 30 and The upper mold 80 cooperates to form an injection molding cavity. The injection molding cavity includes a nozzle flow channel and a product molding cavity. The fixed mold 30 is provided with a left valve seat installation groove inner core 304 and a right valve seat installation groove inner core 305. The fixed mold 30 is provided with Water outlet mold core 301 is arranged. Both the left water inlet core-pulling ...

Embodiment 2

[0045] A mold for manufacturing a plastic faucet body, comprising a mold base, an upper mold 80, the upper mold 80 is provided with a left water inlet core cavity and a right water inlet core cavity, and a detachable left water inlet core cavity is set inside the left water inlet core cavity. The water inlet mold core 501, the right water inlet mold core cavity is provided with a detachable right water inlet mold core 502, and also includes a fixed mold 30, a left water inlet core-pulling mechanism and a right water inlet core-pulling mechanism, the fixed mold 30 and The upper mold 80 cooperates to form an injection molding cavity. The injection molding cavity includes a nozzle flow channel and a product molding cavity. The fixed mold 30 is provided with a left valve seat installation groove inner core 304 and a right valve seat installation groove inner core 305. The fixed mold 30 is provided with Water outlet mold core 301 is arranged. Both the left water inlet core-pulling ...

Embodiment 3

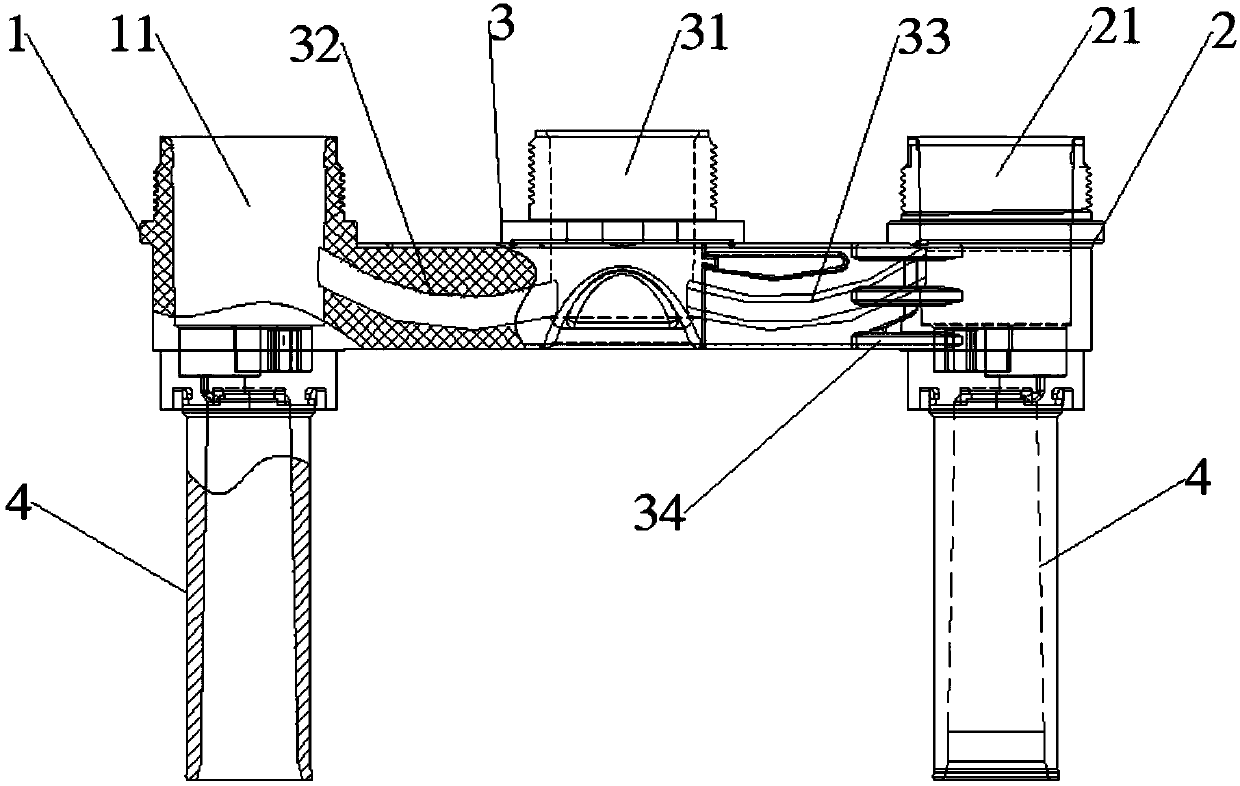

[0049] A plastic faucet body 10, comprising a left water inlet pipe 1 and a right water inlet pipe 2, the left water inlet pipe 1 is provided with a left valve seat installation groove 11, the right water inlet pipe 2 is provided with a right valve seat installation groove 21, and the left water inlet pipe 1 A connecting crossbeam 3 is arranged between the right water inlet pipe 2, and a water outlet 31 is arranged in the middle of the connecting crossbeam 3, and an intermediate waterway is arranged inside the connecting crossbeam 3, and the middle waterway is connected with the left water inlet pipe 1, and the middle waterway is connected with the right water inlet pipe 2 , the middle waterway communicates with the water outlet 32, the middle waterway includes a left water inlet 32 and a right water inlet 33, the left water inlet 32 and the right water inlet 33 are formed on the plane formed by the axis of the left water inlet 1 and the axis of the right water inlet 2 Arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com