A high-speed planetary wheel bearing with high specific pressure and bidirectional rotation

A high-speed planetary wheel, two-way rotation technology, applied in the direction of bearings, shafts and bearings, bearing components, etc., can solve the problems of high vibration and noise of rolling bearings, low life of rolling bearings, etc., to reduce bearing specific pressure, long service life, and reduce assembly The effect of the component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

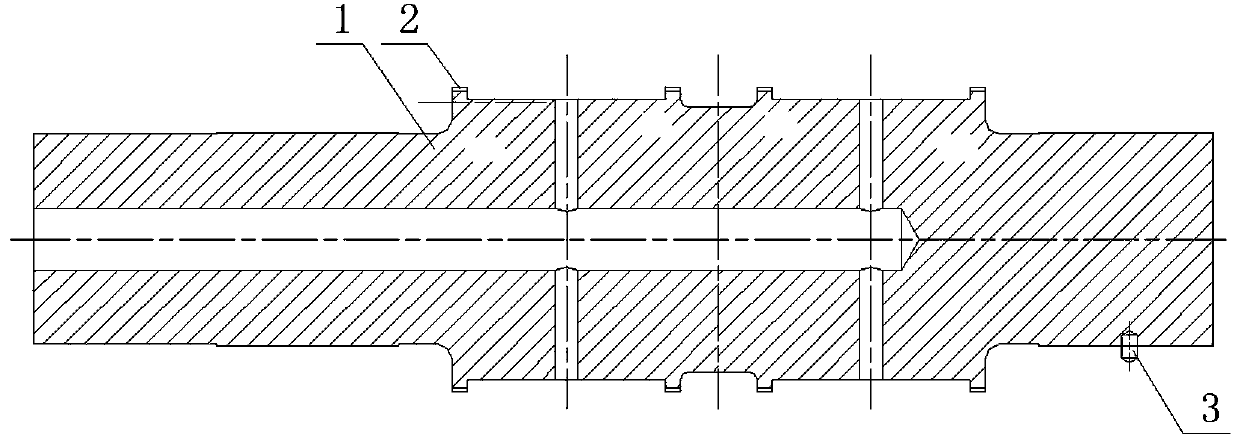

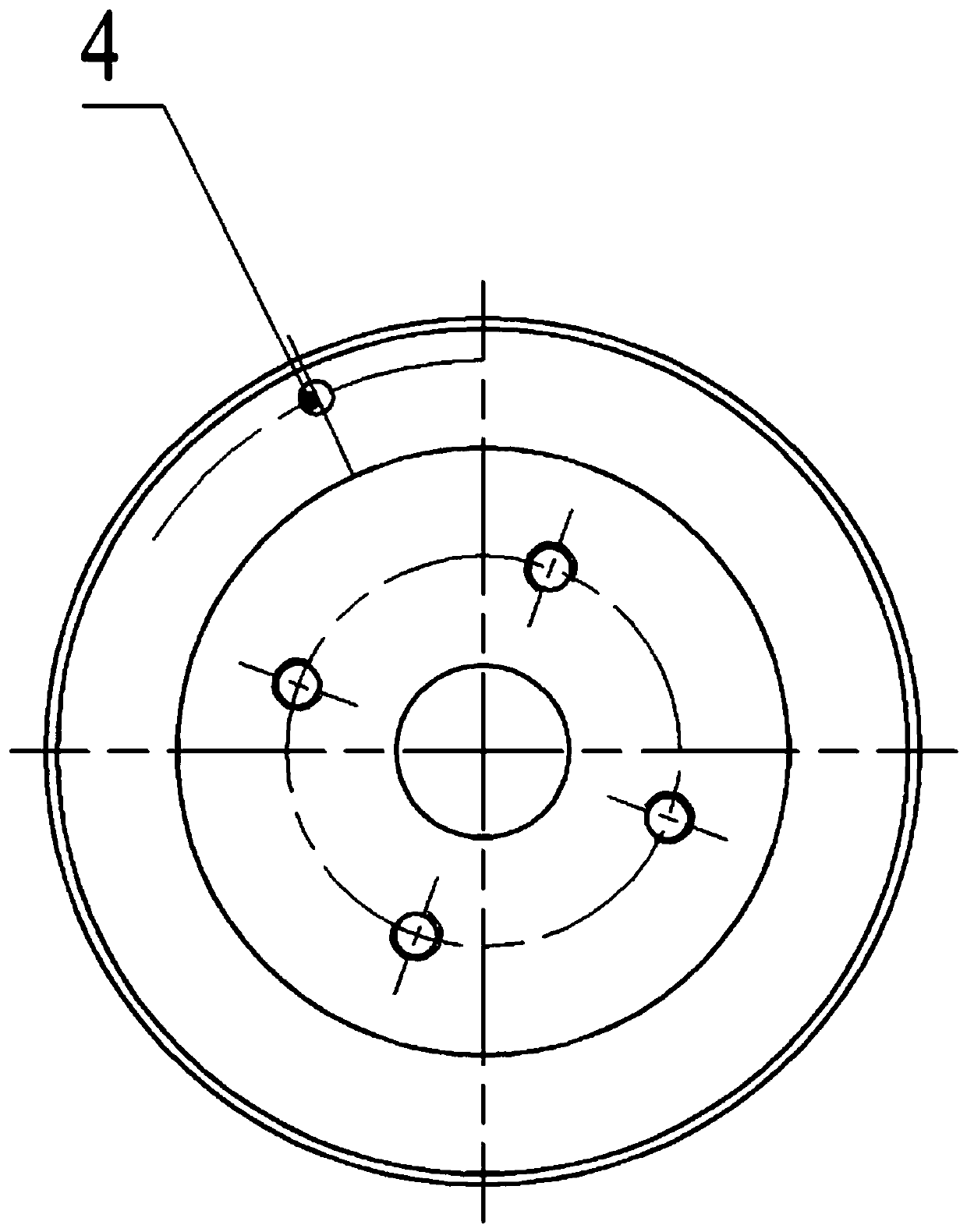

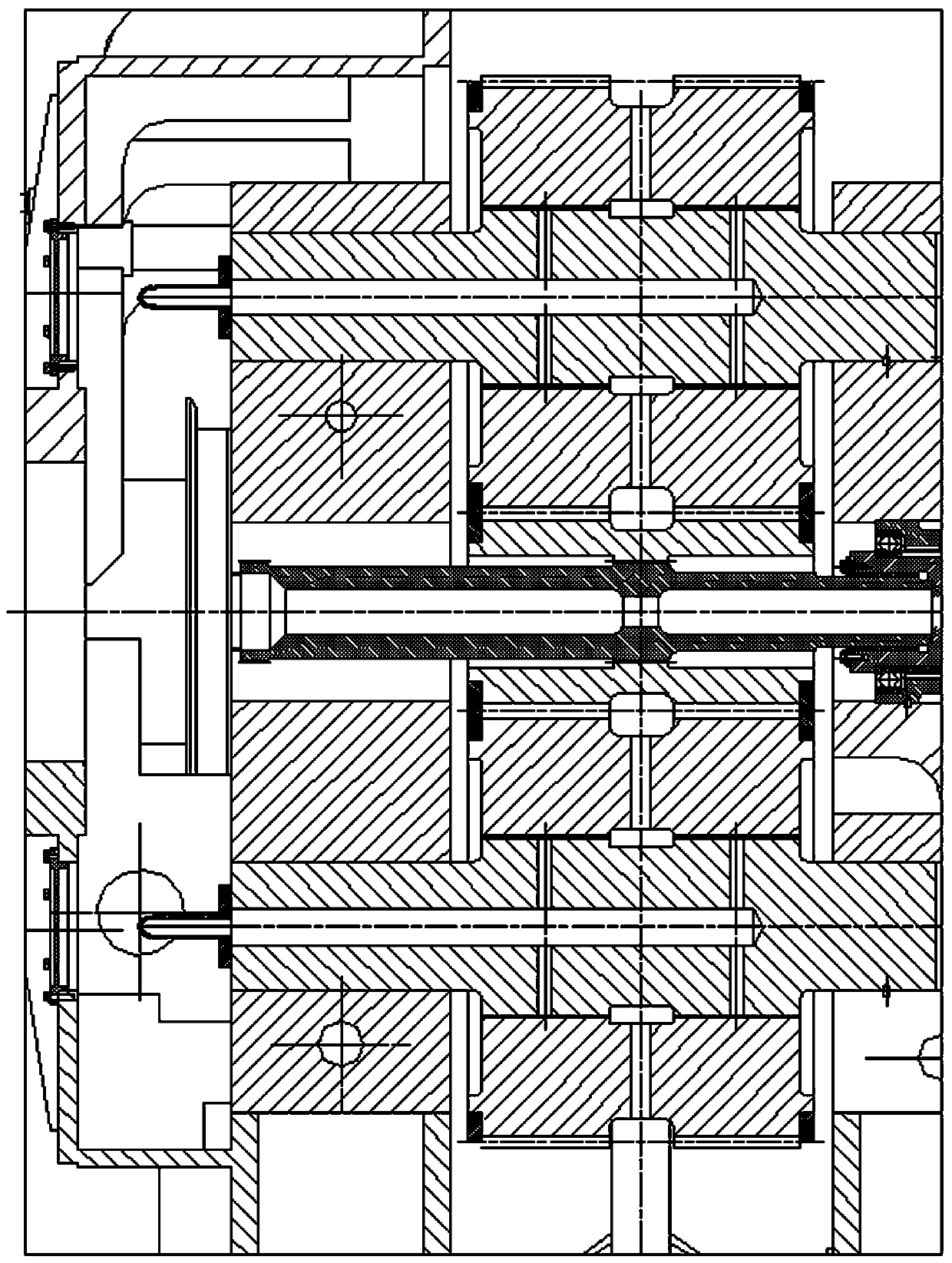

[0013] Referring to each figure, a high-speed planetary wheel bearing with high specific pressure and bidirectional rotation is used. The bearing includes a bearing body 1, a Babbitt alloy 2, a stop pin 3 and a temperature measuring element 4. The Babbitt alloy 2 is divided into two parts and cast on the planetary wheel. The outer surface of the wheel bearing body 1 is divided by an annular groove in the middle. The bearing is divided into two sections in the middle of the bearing body. There are oil inlet grooves on the alloy surface of each section. There are oil guide holes from the inside of the bearing body 1 together with the oil inlet grooves. At the same time, the bearing body 1. The center oil inlet hole is not drilled through, so that the oil inlet hole forms a chamber to ensure the oil inlet pressure. At the same time, a plurality of oil guide holes are processed in the bearing body 1, so that the sliding bearing can supply oil smoothly in the high-speed operating env...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com