Output shaft assembly applied to SHRT unit variable-speed clutch and output shaft arrangement method

An output shaft and clutch technology, applied in mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of large motor capacity, low operation rate, large gap, etc., to reduce assembly components, simplify structure, structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

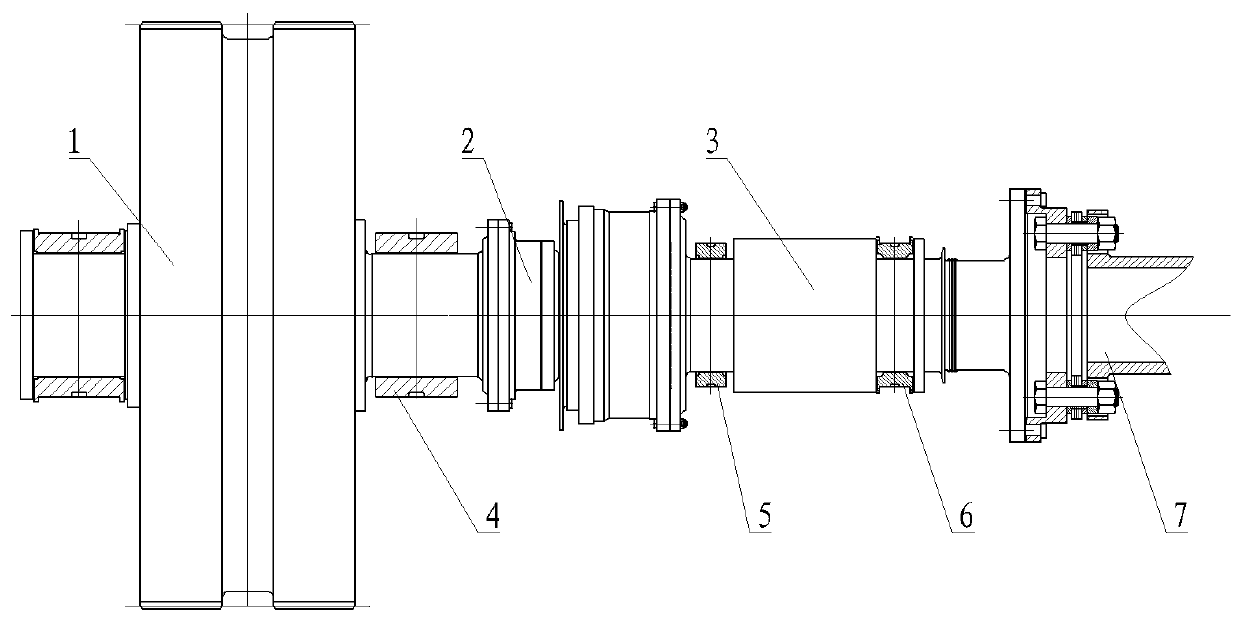

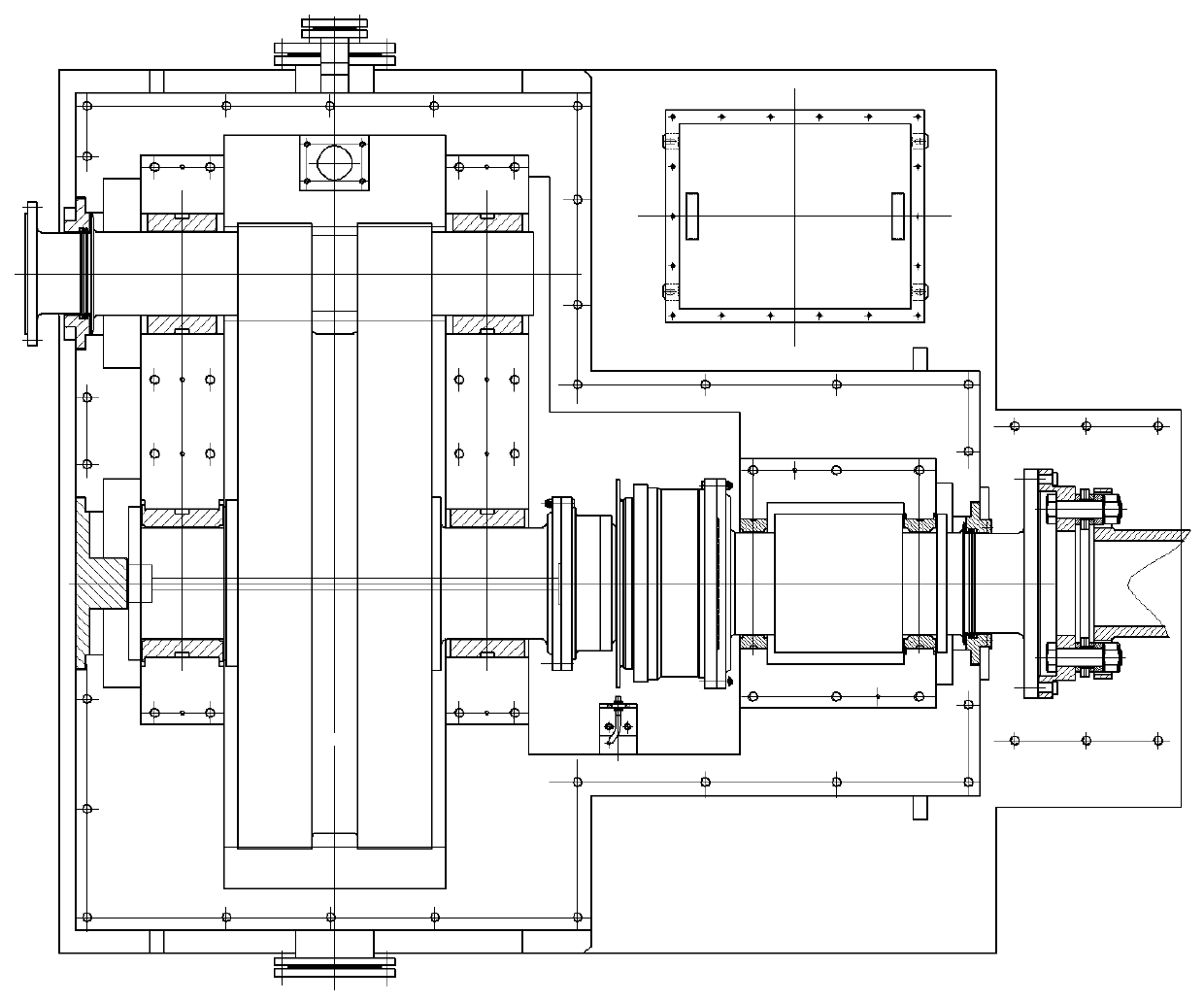

[0015] refer to figure 1 and figure 2 , an output shaft assembly applied to the transmission clutch of the SHRT unit, including a gear shaft 1, a synchronous automatic clutch 2, an output shaft 3, a gear shaft sliding bearing 4, an output shaft front bearing 5, an output shaft rear bearing 6 and a coupling 7 The gear shaft 1 is connected with the synchronous automatic clutch 2, the gear shaft 1 is supported by the gear shaft sliding bearing 4 double points, the other end of the synchronous automatic clutch 2 is connected with the output shaft 3, and the output shaft 3 is connected by the output shaft front bearing 5 and the output shaft rear bearing 6 Two-point support, in which the front bearing 5 of the output shaft is a supporting sliding bearing, and the rear bearing 6 of the output shaft is a thrust bearing, which cooperates with the thrust surface structure on the output shaft 3 to achieve the functions of positioning and bearing external axial force. The balance plate...

Embodiment 2

[0017] An output shaft arrangement method applied to the output shaft assembly of the variable speed clutch of the SHRT unit, the output shaft of the output shaft assembly adopts the arrangement form of double fulcrums, and the system stability is enhanced by adding a counterweight plate and matching sliding bearings, The output shaft is a rigid shaft, one end of which is rigidly connected to the output assembly of the synchronous automatic clutch, the input assembly of the synchronous automatic clutch is rigidly connected to the gear shaft, and the other end is rigidly connected to the elastic coupling, and the output shaft is supported by two sliding bearings with a span , one of the sliding bearings is a support bearing, the other is a thrust bearing, and the gear shaft connected with the synchronous automatic clutch is supported by two sliding bearings. The arrangement of double fulcrums and elastic links at both ends has higher stability and reliability. At the same time, ...

Embodiment 3

[0019] The output shaft arrangement method of the second embodiment applied to the output shaft assembly of the variable speed clutch of the SHRT unit is also applied to the variable speed clutches of the BPRT unit and the steam-electric dual-drive induced draft unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com