Ultralow-temperature tool-aid-type fixing ball valve and assembling method thereof

A technology for fixing ball valves, assembly methods, applied in the direction of valve details, valve devices, valve housing structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

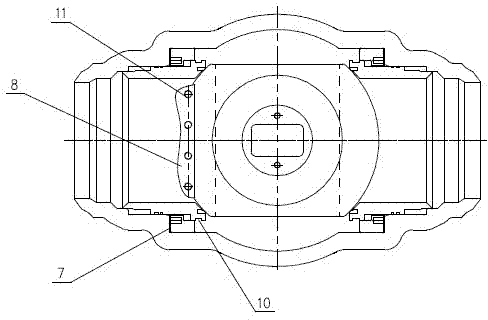

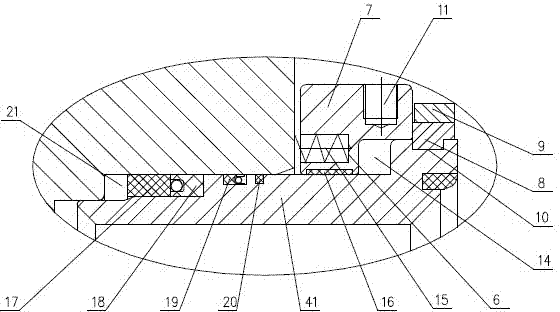

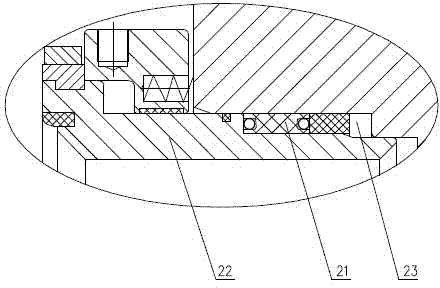

[0023] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

[0024] An assembly method for an ultra-low temperature top-entry fixed ball valve. The installation steps are as follows: First, use tooling to put the elastic support ring, left valve seat, and right valve seat assembly into the valve seat hole of the valve body, adjust the assembly size of the ball and the valve seat, and place the ball When the valve is in the open state, put it into the valve chamber, then rotate the ball 90°C to the closed state, use the tooling to stretch the elastic support ring to expose the positioning parts of the left valve seat and the right valve seat, and then pass through the fixed process hole on the elastic support ring Use tooling to fix the elastic support ring on the positioning part, then remove the tooling that stretches the elastic support ring, use the tooling to snap the half-open valve seat positioning ring into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com