Ball valve

A ball valve and valve cavity technology, applied in the field of valves with spherical valve elements, can solve problems such as large pressure loss, affecting the mass flow of saturated water in the pipeline, and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

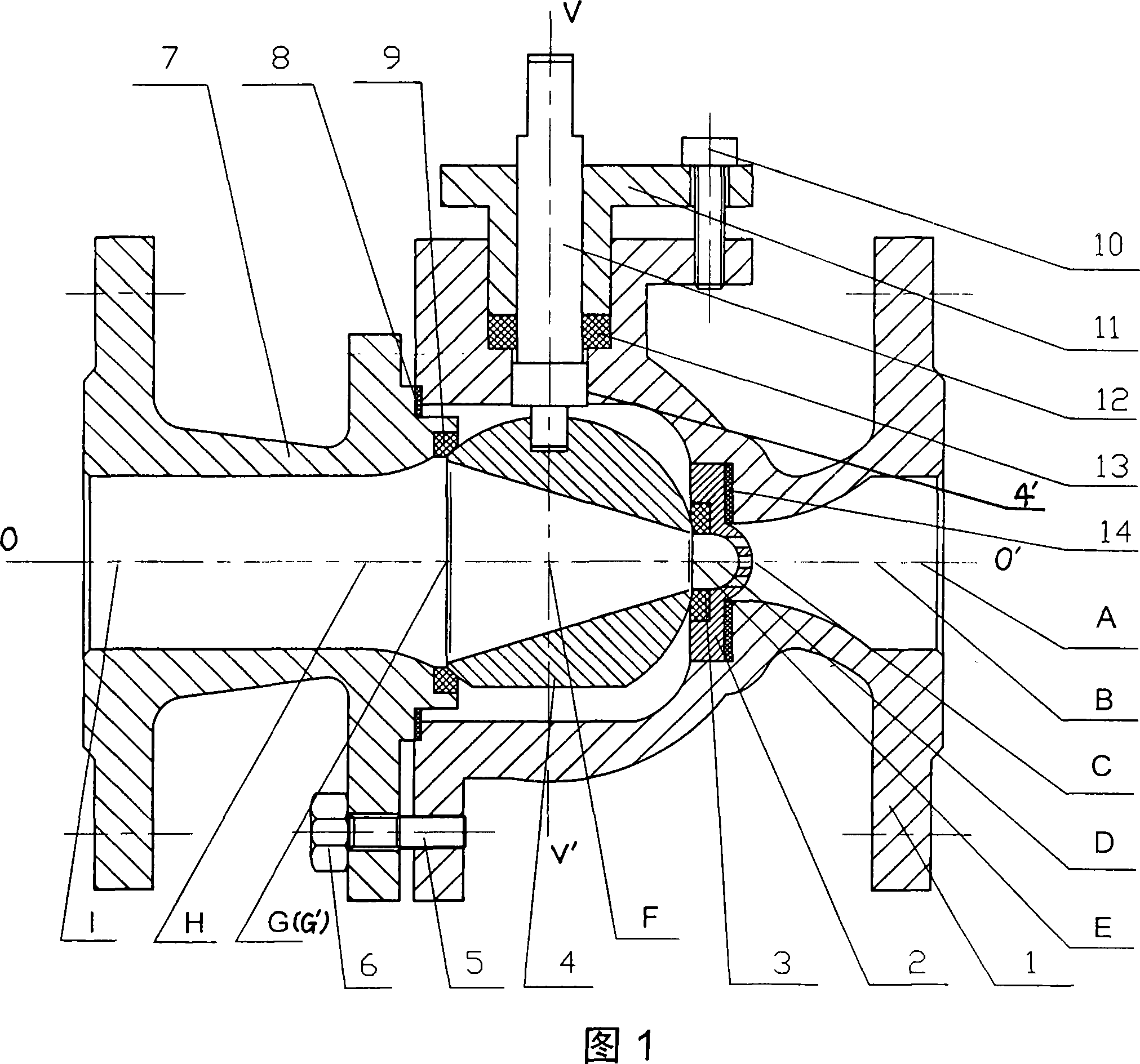

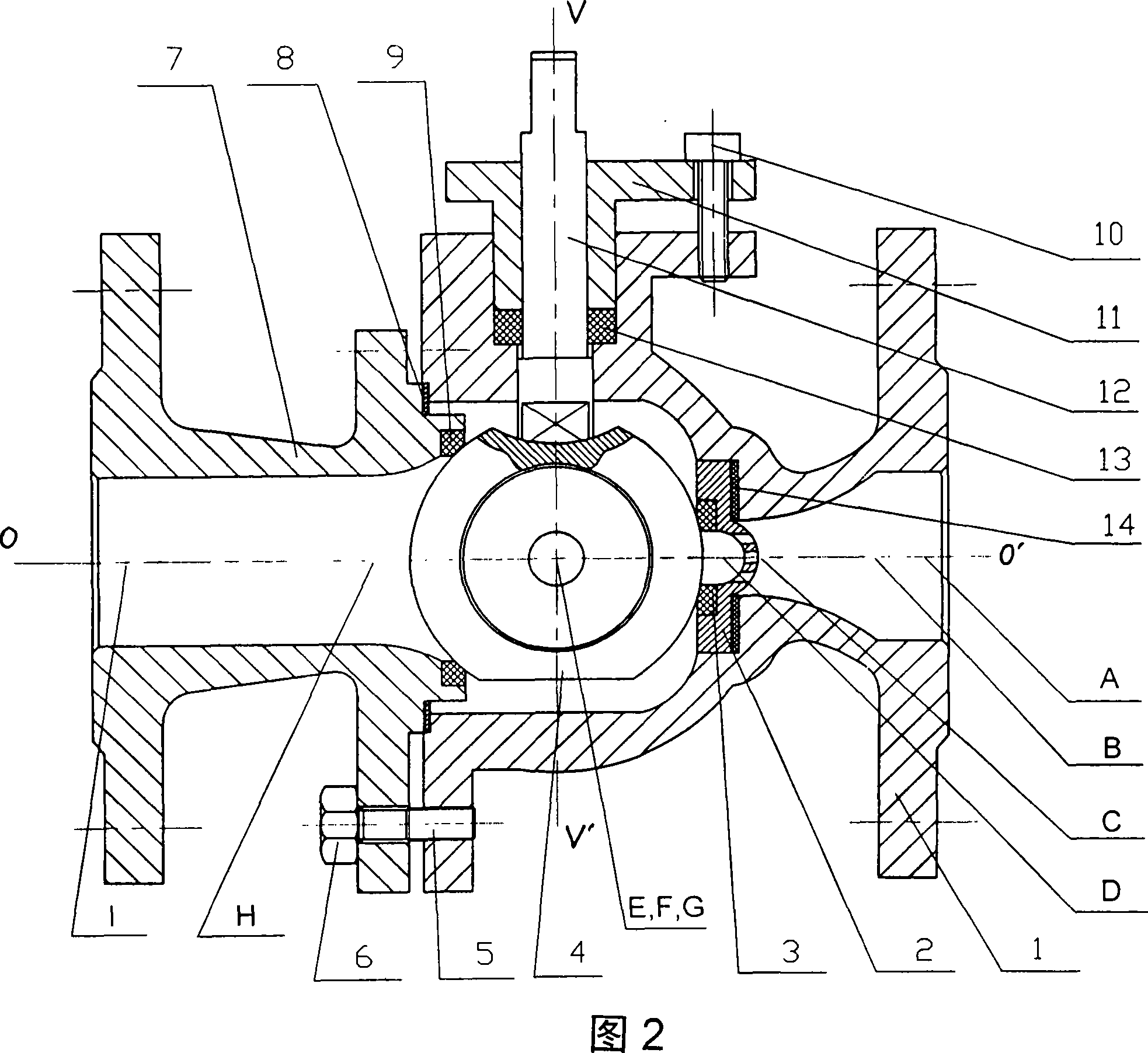

[0008] As shown in Figure 1, the inner surface of the valve cavity of the left valve body 7 from the inlet I of the valve cavity of the left valve body 7 to the starting point H of left diffusion is a cylindrical surface. The valve cavity of the valve body 7 is a conical surface, the left diffuser starting point H is the intersection of the geometric circular plane and the valve cavity axis OO' at the intersection of the conical surface and the cylindrical surface, and the left diffuser end point G is the intersection of the conical surface and the sphere 4 The intersection point of the geometric circular plane and the axis OO' of the valve cavity. Point F is the intersection of the center line VV' of the sphere 4 and the axis OO' of the valve cavity. Point E is the intersection of the geometric circular plane at the intersection of the right valve body 1 and the sphere 4 and the axis OO' of the valve chamber. The valve cavity of the right valve body 1 from the right diffuser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com