High-pressure high-temperature ceramic adjusting ball valve

A high-pressure, high-temperature, regulating ball technology, applied in the field of regulating valves, can solve the problems of large friction coefficient, decreased system operation stability, liquid leakage, etc., and achieves the effect of simple overall structure design, significant economic benefits, and reduced friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

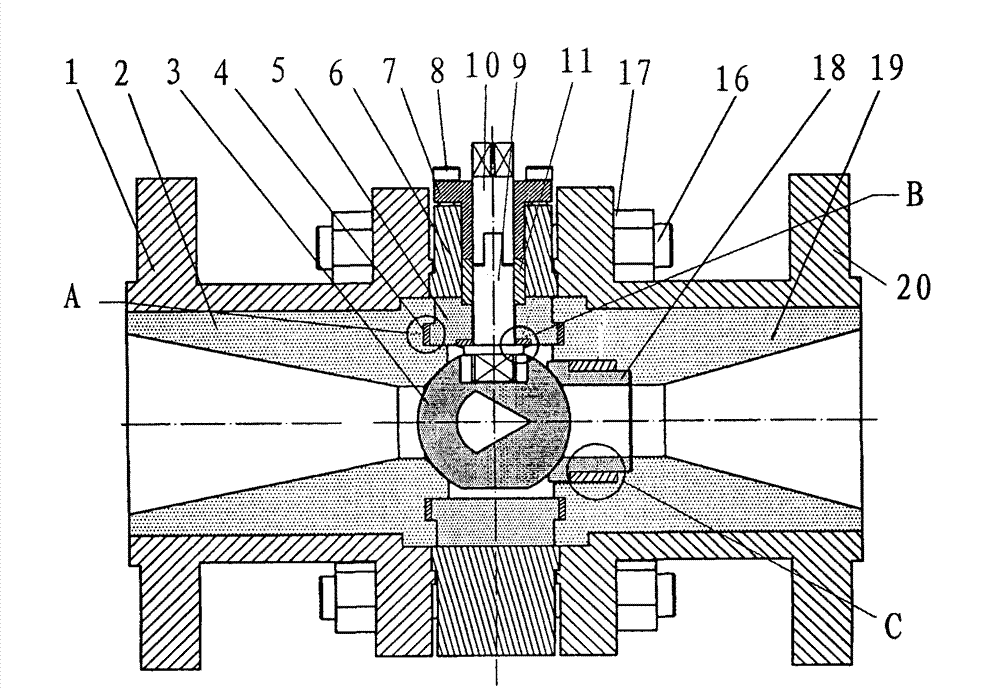

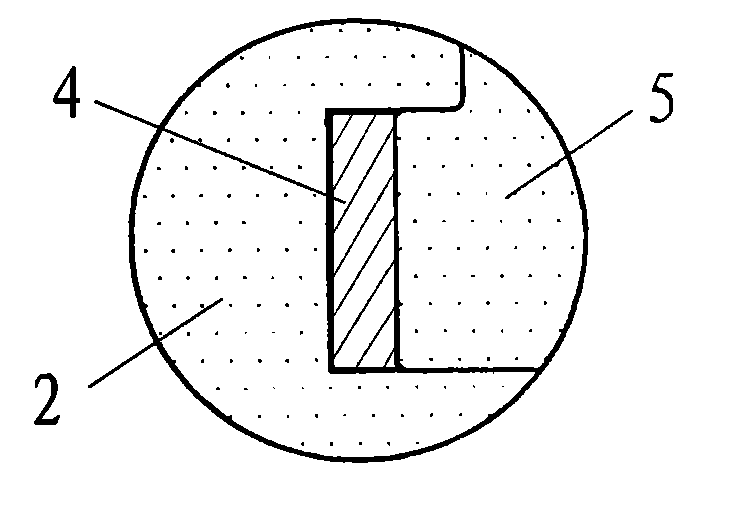

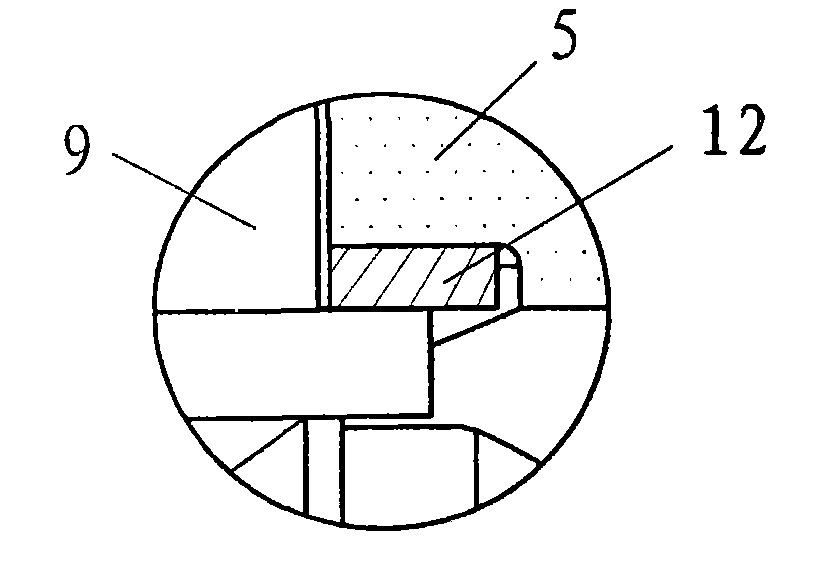

[0015] See Figure 1 to Figure 4 , the specific embodiment of the present invention is as follows: comprise left flange 1 and right flange 20, be provided with valve body 6 and valve inner liner 5 between left and right flanges (1, 20), bolt 16 and nut 17 connect left and right method The flange (1, 20) is fastened. The above structure is the basic structure of a general ball valve. The key is that the left flange 1 is provided with a left valve seat 2 made of ceramics and the right flange 20 is provided with a right valve seat 19 made of ceramics. The left and right valve seats (2, 19) are closely connected with the left and right flanges (1, 20) respectively and solidly connected to form a flange with a ceramic inner surface. The above-mentioned left and right valve seats (2, 19) and the left and right flanges (1 , 20) The connection method can be through adhesive bonding, or sintering or other conventional or existing methods after coating ceramics on the inner surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com