Exhaust gas purification device for marine diesel engine using low-quality fuel such as fuel oil containing high concentration of sulfur

A technology for diesel engine and exhaust gas, which can be used in exhaust devices, combustion engines, internal combustion piston engines, etc., and can solve problems such as insufficient PM capture efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0137] Next, the present invention will be described in more detail using examples.

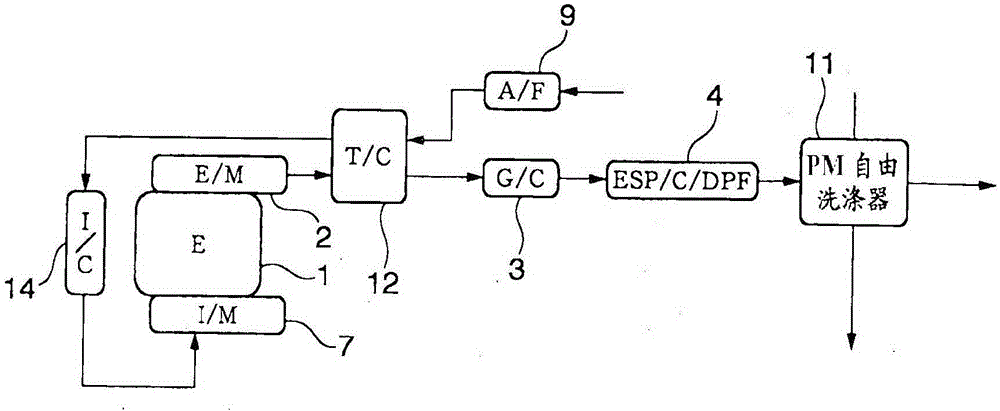

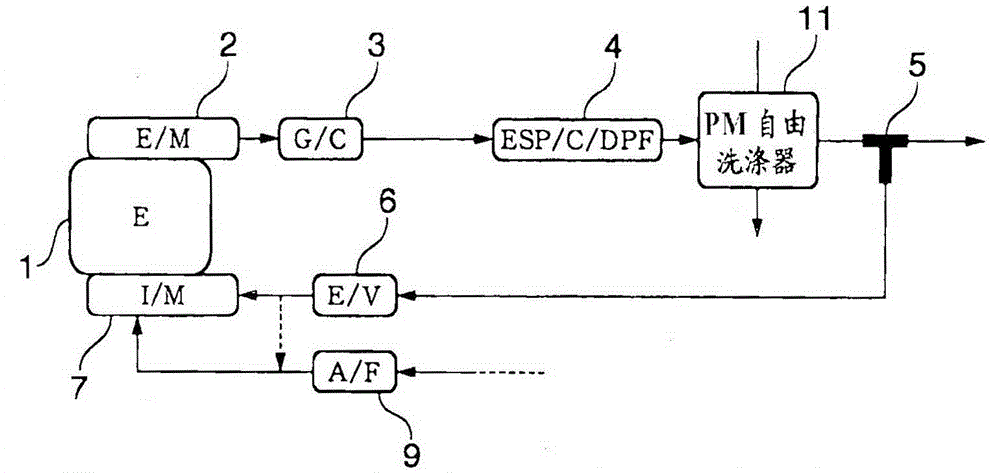

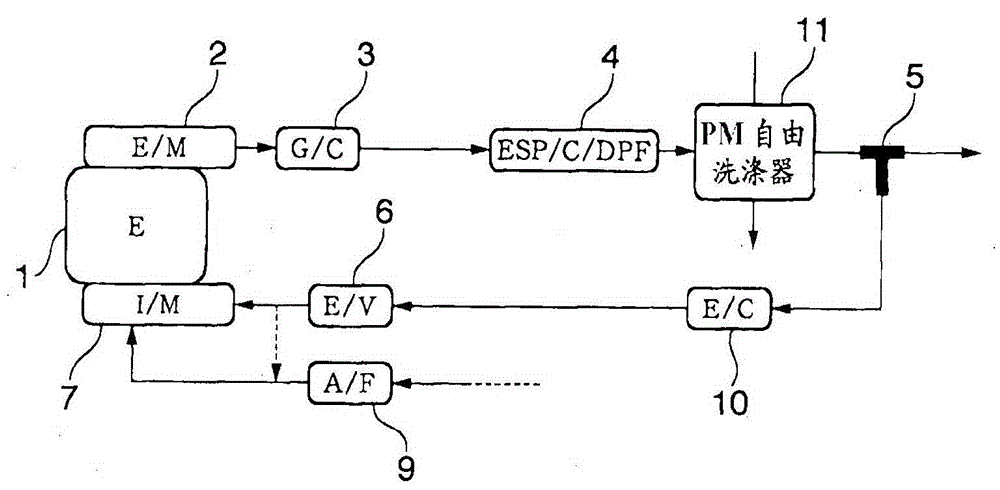

[0138] In order to confirm the effects of the present invention, the following tests were carried out on marine diesel engines under the conditions shown in Table 1, and the characteristics of the exhaust gas and the characteristics of the scrubber treated water of each example and comparative example are shown below. The basic characteristic is to use the exhaust gas purification device without Figure 20 The result in the case of the device with the structure shown, the conventional example uses the structure based on Non-Patent Document 2 Figure 26 Shown are the results in the case of an exhaust gas purification device for a diesel engine. In addition, the present invention 1 uses figure 1 In the case of the device shown in the first example results, the present invention 2 is used Figure 11 The results shown in the case of the device of the eleventh embodiment, the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com