Double-channel butterfly valve structure

A dual-channel, butterfly valve technology, applied in the direction of adding non-fuel substances to fuel, internal combustion piston engines, engine components, etc., can solve the problem of high cost, achieve simple structure, high EGR rate, and achieve the effect of internal purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

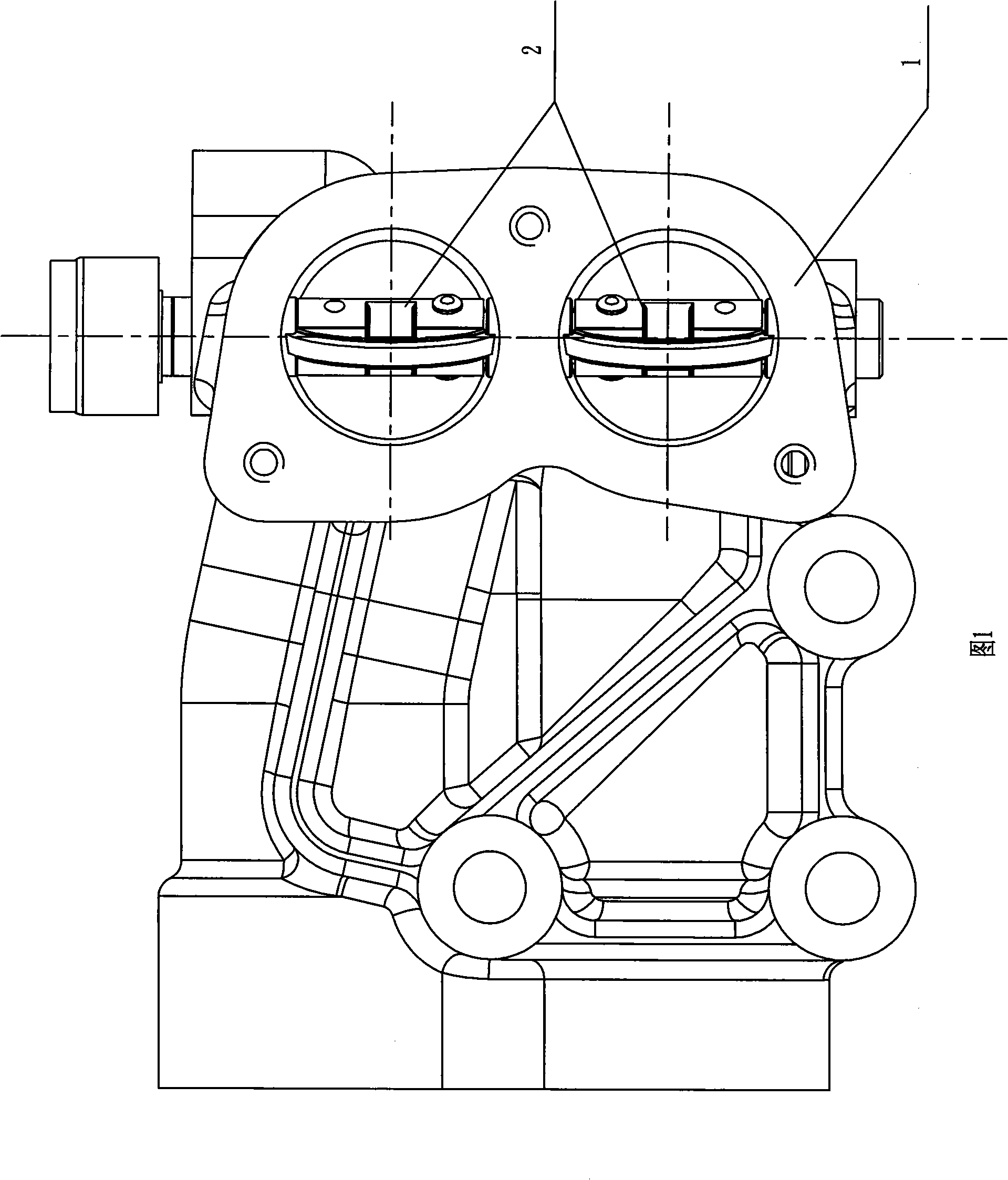

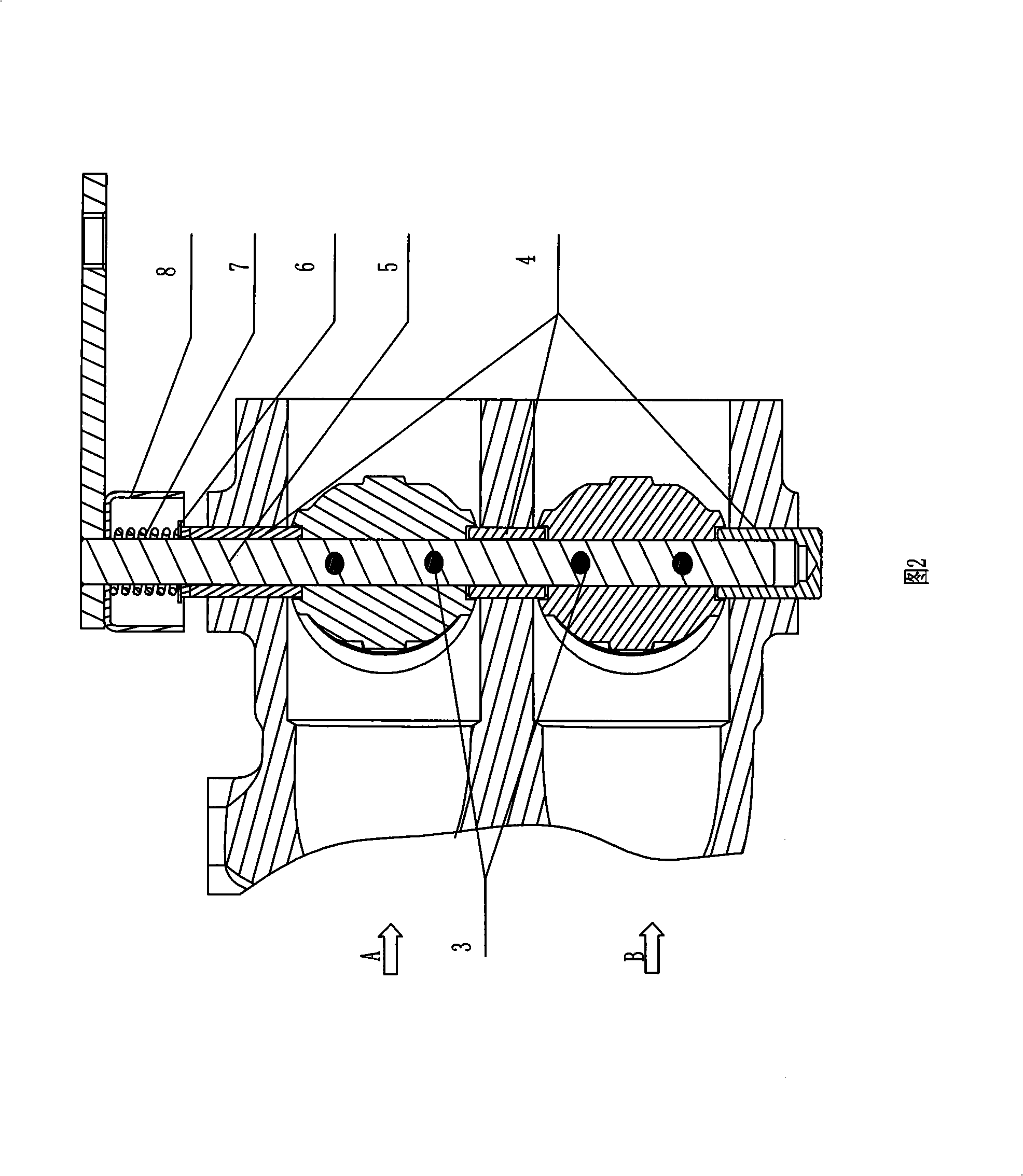

[0011] As shown in Figure 1 and Figure 2, it includes EGR valve body 1, two EGR valve plates 2, rivet 3, adjustment sleeve 4, drive shaft assembly 5, sealing gasket 6, compression spring 7 and protective sleeve 8, etc.

[0012] The EGR valve of the present invention adopts two waste gas passages (A, B) arranged on the EGR valve body 1 of the EGR valve, and the drive shaft assembly 5 is installed in the EGR valve body 1, and the drive shaft assembly 5 is fixed on the EGR valve by an adjustment sleeve. In body 1. The two EGR valve plates 2 are fixed on the drive shaft of the drive shaft assembly 5 through rivets 3, and the two EGR valve plates 2 are simultaneously driven by one drive shaft in the drive shaft assembly 5, and the two EGR valve plates 2 are driven by Controlled by the same drive shaft. An adjustment sleeve 4 is arranged on the drive shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com