Exhaust gas recirculation system

A technology of exhaust gas and recirculation, which is applied in exhaust gas recirculation, fuel heat treatment device, charging system, etc., can solve problems such as corrosion, improve EGR rate, maintain NOx reduction effect, and improve cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0039] 1. Overall structure

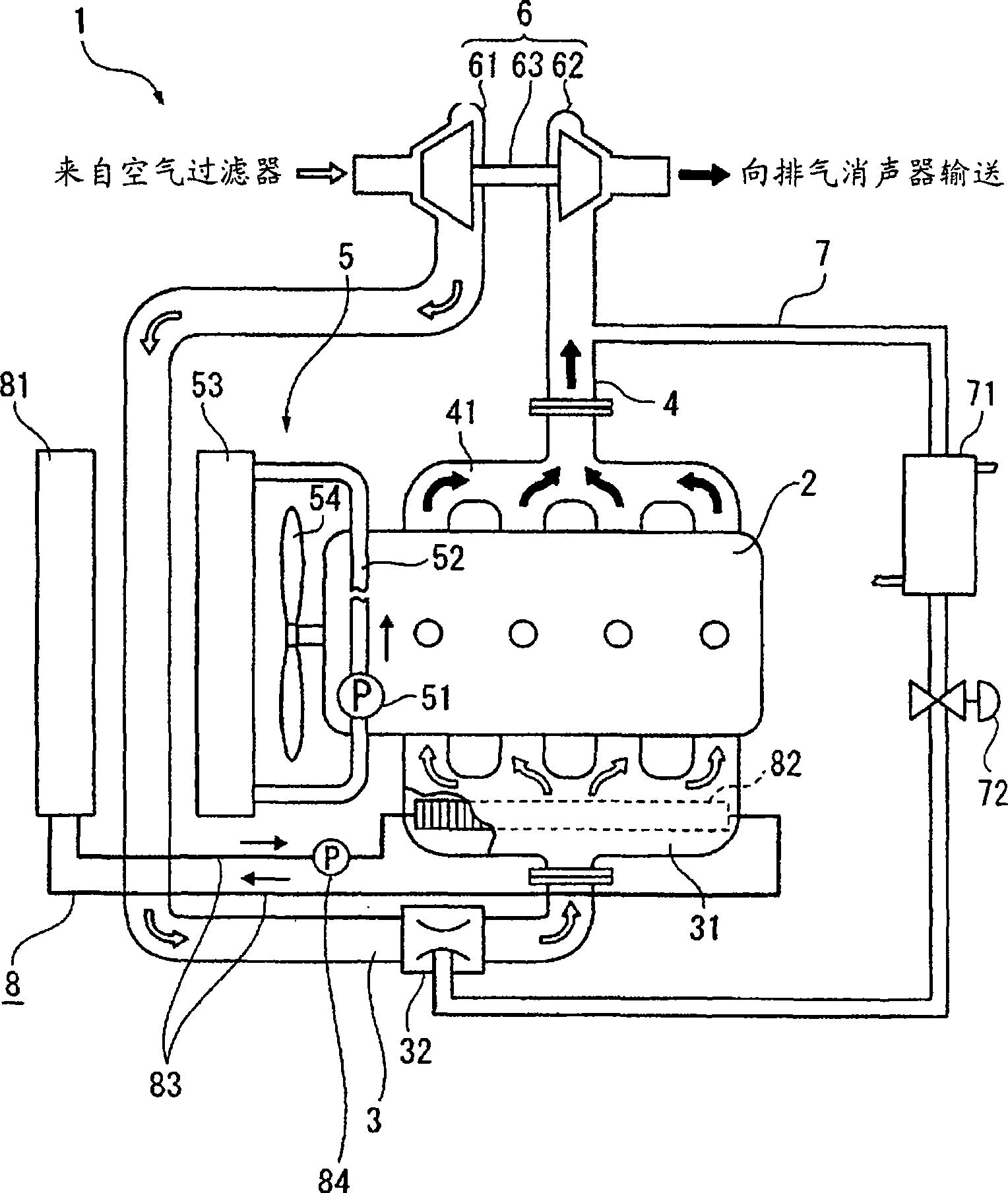

[0040] figure 1 It is a schematic diagram showing the EGR system of the diesel engine (internal combustion engine) 1 according to the first embodiment of the present invention.

[0041] The structure of the diesel engine 1 has: an inline four-cylinder engine body 2, an intake path 3 for supplying intake air to the combustion chamber, an exhaust path 4 for discharging exhaust gas to the outside of the combustion chamber, and an engine cooling refrigeration unit for cooling the diesel engine 1. The agent circulation path 5 is provided with an exhaust turbocharger 6 straddling between the upstream side of the intake path 3 and the downstream side of the exhaust path 4 . In addition, these devices are controlled by an engine controller that outputs a control signal through an operator's operation. figure 1 In , illustration of the engine controller is omitted.

[0042] Between the intake path 3 and the engine body 2, an intake manifold 31 is instal...

no. 2 approach

[0076] Next, a second embodiment of the present invention will be described. In addition, in the following description, the same code|symbol is attached|subjected to the same part as what already demonstrated, and the description is abbreviate|omitted.

[0077] In the aforementioned first embodiment, the liquid-cooled cooling device 8 employs a cooling water circulation structure independent of the engine-cooling refrigerant circulation path 5 of the diesel engine 1 .

[0078] In contrast, as Figure 4 As shown, the liquid-cooled cooling device 18 of the second embodiment is different in that a branch pipe path 182 is provided in a part of the piping path 52 for circulating the cooling water in the engine cooling refrigerant circulation path 5 of the diesel engine 1 , the cooling water is supplied to the heat exchanger 181 by the pump 51 .

[0079] In the present embodiment, since a part of the cooling water in the engine cooling refrigerant circulation path 5 is configured ...

no. 3 approach

[0088] Next, a third embodiment of the present invention will be described.

[0089] In the aforementioned first embodiment, one exhaust turbocharger 6 is installed in the diesel engine 1 .

[0090] In contrast, as Image 6 As shown, the third embodiment is different in that a twin-turbo type in which two exhaust turbochargers 6 are mounted on the diesel engine 1 is adopted.

[0091] In addition, the difference is that an air-cooled ATAAC (Air To Air After Cooler: air-to-air aftercooler) 33 is provided between the two exhaust turbochargers 6 on the side of the intake path 3 .

[0092] According to the third embodiment as described above, in addition to the basic effects described in the first embodiment, the two exhaust turbochargers 6 can also be used to improve the combustion rate, which is supplied to the intake manifold. The increase of the compression rate of the gas in 31 improves and promotes the cooling of the intake path 3. This cooling is performed by the ATAAC33 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com