System and method for electrochemical desulfurization of organic solid waste anaerobic fermentation biogas

An anaerobic fermentation, organic solid waste technology, applied in the field of biogas electrochemical desulfurization system, can solve the problems of incomplete solution absorption, secondary pollution, complex process, etc., to achieve long-term recycling, avoid work interruption, and efficient reaction stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

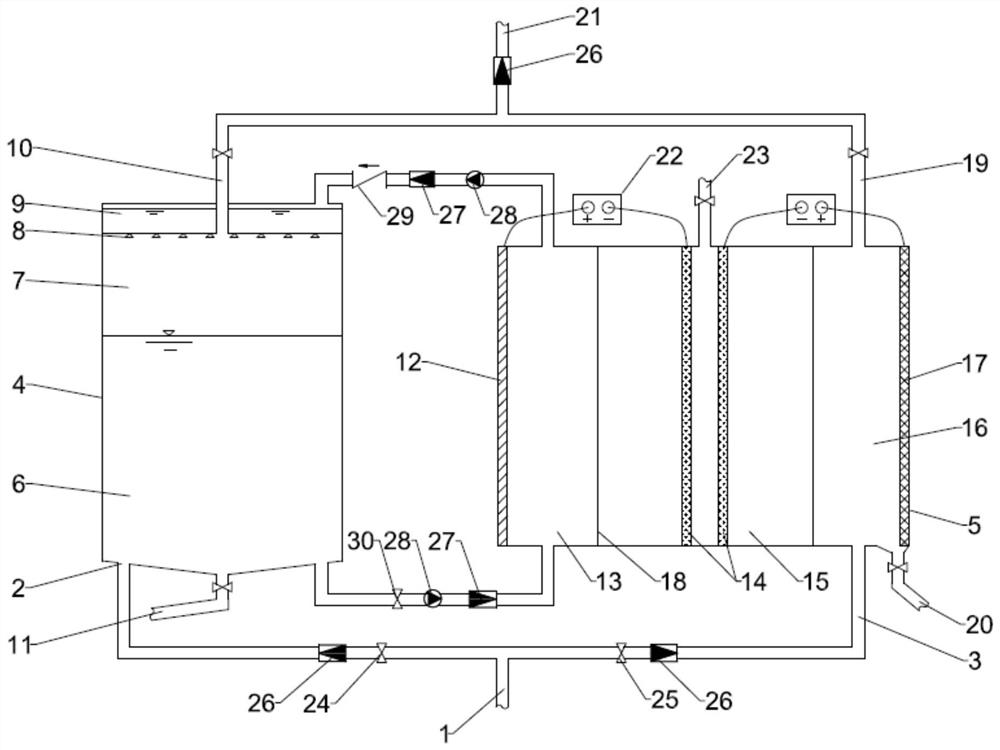

[0040] Example 1: A system for electrochemical desulfurization of biogas by anaerobic fermentation of organic solid waste, including an absorption tank 4 and an electrochemical reaction tank 5; the electrochemical reaction tank 5 is an anode chamber I13 and a cathode chamber in sequence from left to right 15 and the anode chamber II 16, including the proton exchange membrane 18 between the anode I12, the cathode 14, the anode II17, the anode chamber I13, the cathode chamber 15 and the anode chamber II16 respectively; the absorption pool 4 and the bottom of the anode chamber II16 and the top are respectively provided with air inlet a 2, air inlet b 3, air outlet a 10 and air outlet b 19, and the biogas is divided into two paths from the total air inlet 1 into the absorption pool 4 and the electrochemical reaction pool 5, respectively After desulfurization by reaction, the biogas is collected and utilized from the top general gas outlet 21. The invention can realize the recovery...

Embodiment 2

[0044] Embodiment 2: A method for electrochemical desulfurization of biogas by anaerobic fermentation of organic solid waste, comprising the following steps:

[0045] (1) After anaerobic fermentation of organic solid waste, the biogas is divided into two paths a and b to enter the absorption pool 4 and the anode chamber II 16 of the electrochemical reaction pool respectively, and the biogas volume of the two paths is controlled by valve a 24 , valve b 25 and gas flow meter 26 1:1;

[0046] (2) One path of biogas enters from the biogas inlet a2 at the left bottom of the absorption pond, and under acidic conditions, it is mixed with the absorption liquid in the pond with 6 5mol / L FeCl 3 Solution reaction, H 2 S is reduced to simple sulfur. The biogas that has been absorbed once escapes from the upper liquid surface of the absorption liquid 6, and reacts with the absorption liquid spilled from the sprinkler 8 in the spray area 7 for secondary absorption, and the treated biogas ...

Embodiment 3

[0051] Embodiment 3: When the absorption pool 4 breaks down, the valve a 24 is closed, the valve b 25 is opened, and the biogas only enters into the anode chamber II 16 of the electrochemical reaction pool.

[0052] The biogas enters from the biogas inlet b3 at the bottom of the anode chamber II16. The solution in the anode chamber II is 3mol / L KI and 1mol / L KOH solution. After the anode II17 is connected to the cathode 14 circuit, under alkaline conditions, I - Electron loss is oxidized to IO 3 - , IO 3 - with H 2 S reacts to generate elemental sulfur, which is deposited into the lower collection hopper, and elemental sulfur can be collected through the sulfur discharge pipe b 20. H produced at the anode + Enter the cathode chamber 15 through the proton exchange membrane 18 and be reduced to H 2 , through H 2 The air outlet 23 is discharged.

[0053] The principle of the electrochemical reaction cell 3 of this embodiment is as follows:

[0054] Cathode: 2H + +2e - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com