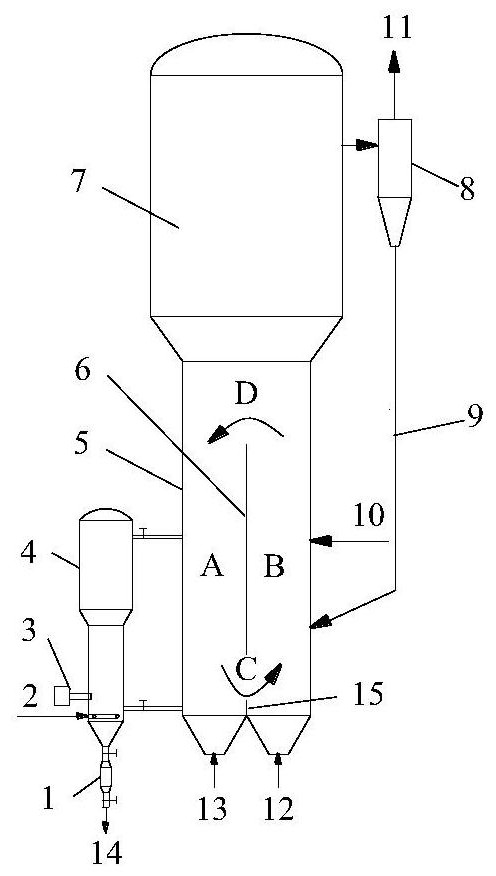

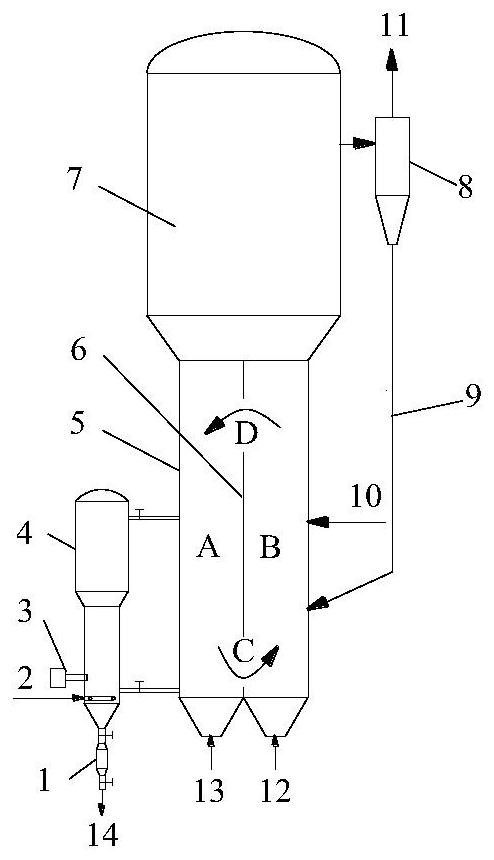

Differential fluidized bed reaction device and reaction method

A fluidized bed reactor and reaction device technology, which is applied in gasification process, granular/powder fuel gasification, manufacture of combustible gas, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The carbonaceous feedstock loaded with the catalyst enters the pyrolysis zone of the inner circulating fluidized bed reactor, and after being fluidized by the fluidized air, it is rapidly mixed with the hot particle carrier from the gasification zone in the circulating return zone, and then pyrolyzed rapidly. , the pyrolyzed tar gas, the pyrolyzed semi-coke particles 1, the gasified particles and the crude gas from the gasification zone enter the settling section together with the gas-solid separation equipment for multi-stage separation. The separated tar-rich crude gas is collected, and the rest of the gasification particles separated by the sedimentation section enter the gasification zone together with the semi-coke particles 1 and the semi-coke particles 2 passing through the circulating feed zone and come from the bottom of the gasification zone. The gasification agent is mixed and gasified, and another part of the fine powder particles separated by the gas-solid s...

Embodiment 2

[0043]The carbonaceous feedstock loaded with the catalyst enters the pyrolysis zone of the inner circulating fluidized bed reactor, and after being fluidized by the fluidized air, it is rapidly mixed with the hot particle carrier from the gasification zone in the circulating return zone, and then pyrolyzed rapidly. , the pyrolyzed tar gas, the pyrolyzed semi-coke particles 1, the gasified particles and the crude gas from the gasification zone enter the settling section together with the gas-solid separation equipment for multi-stage separation. The separated tar-rich crude gas is collected, and the rest of the gasification particles separated by the sedimentation section enter the gasification zone together with the semi-coke particles 1 and the semi-coke particles 2 passing through the circulating feed zone and come from the bottom of the gasification zone. The gasification agent is mixed and gasified, and another part of the fine powder particles separated by the gas-solid se...

Embodiment 3

[0046] The carbonaceous feedstock loaded with the catalyst enters the pyrolysis zone of the inner circulating fluidized bed reactor, and after being fluidized by the fluidized air, it is rapidly mixed with the hot particle carrier from the gasification zone in the circulating return zone, and then pyrolyzed rapidly. , the pyrolyzed tar gas, the pyrolyzed semi-coke particles 1, the gasified particles and the crude gas from the gasification zone enter the settling section together with the gas-solid separation equipment for multi-stage separation. The separated tar-rich crude gas is collected, and the rest of the gasification particles separated by the sedimentation section enter the gasification zone together with the semi-coke particles 1 and the semi-coke particles 2 passing through the circulating feed zone and come from the bottom of the gasification zone. The gasification agent is mixed and gasified, and another part of the fine powder particles separated by the gas-solid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com