Thermoplastic elastomer mixed soft segment and preparation method thereof

A thermoplastic elastomer, soft segment technology, applied in the field of copolymers, can solve the problems of uncontrollable reaction, unavoidable, unstable isocyanate group, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

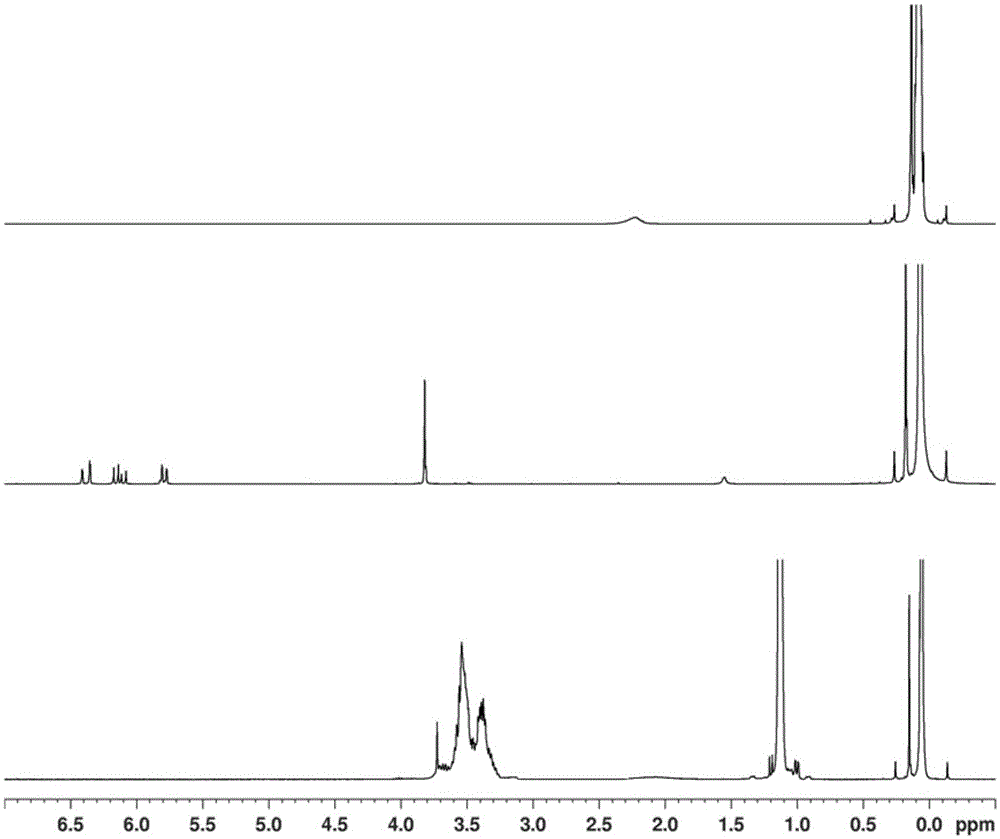

Image

Examples

Embodiment Construction

[0008] Technical scheme of the present invention is as follows:

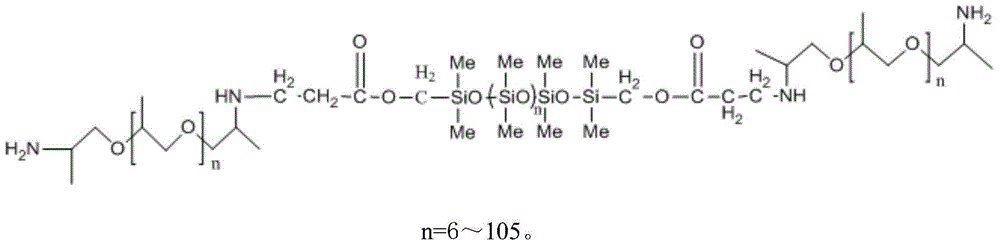

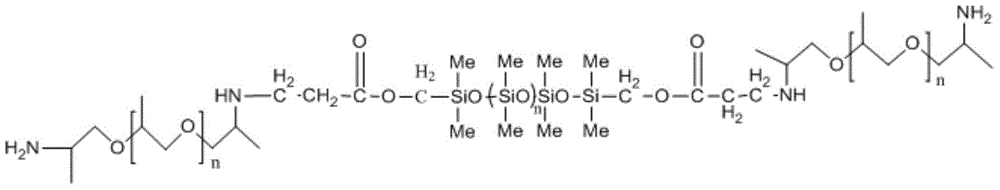

[0009] A mixed soft segment of a thermoplastic elastomer, the mixed soft segment is a polyether-polysiloxane mixed segment polymer, the structural formula is as follows:

[0010]

[0011] The preparation method of the mixed soft segment of the above-mentioned thermoplastic elastomer comprises the following steps:

[0012] (1) In organic solvent A, (acrylate group methyl) dimethacrylate group silane reacts with hydroxyl-terminated polydimethylsiloxane, solvent A is removed, and acrylate group group-terminated polydimethylsiloxane is obtained. Silicone;

[0013] (2) At room temperature, dissolve the amino-terminated polyether in solvent B, under the protection of an inert gas, heat up to 15-30°C, add the acrylate-methyl-terminated polysiloxane prepared in step (1), Insulate and stir for 12-24 hours to carry out the polymerization reaction. After the reaction, the solvent B is removed in vacuum at 20-60° C. to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com