Method for calculating stress intensity factor of butt joint circumferential weld crack tip of misaligned pipeline

A stress intensity factor and weld crack technology, which is applied in the field of calculation of the stress intensity factor at the crack tip of the butt girth weld of the pipeline with staggered edges, can solve the problem that the stress intensity factor of the composite defect crack tip cannot be calculated, etc. Regional stress and strain distribution, the effect of clear characterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

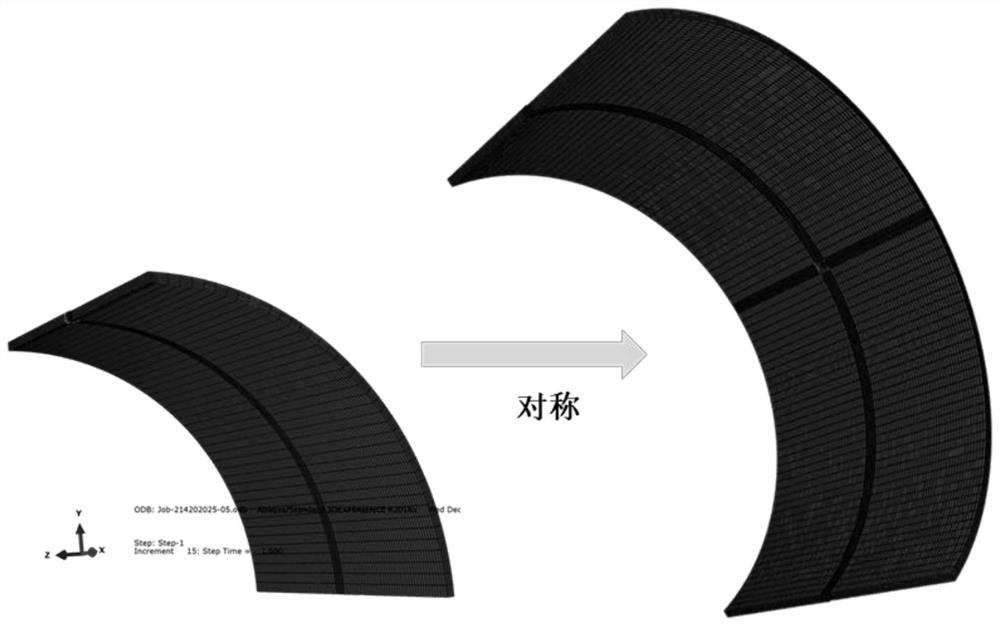

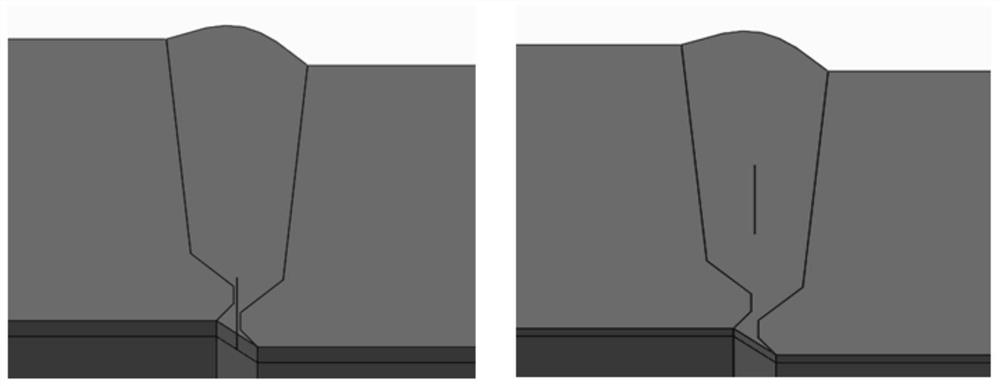

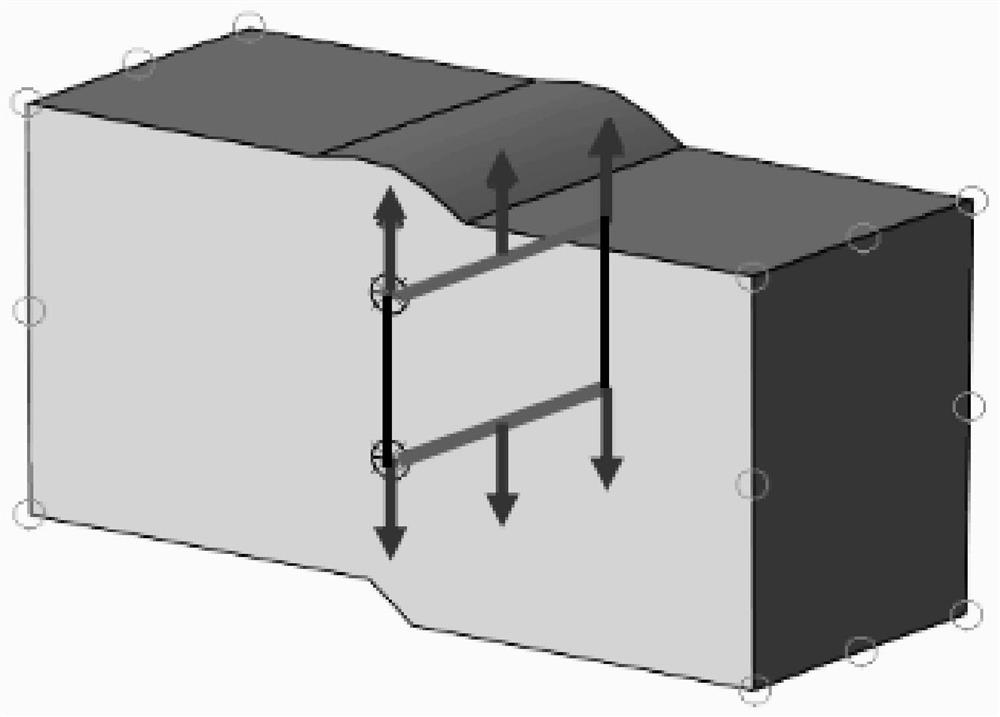

[0063] The calculation method of the stress intensity factor of the crack tip of the girth weld of the butt joint of the pipeline with misalignment. Taking a natural gas pipeline as an example, the girth weld defect accounts for the largest proportion of failures. The pipeline material is X80 pipeline steel with an outer diameter of 1422mm ; Among them, the mechanical properties of X80 pipeline steel are shown in Table 1:

[0064] Table 1

[0065]

[0066] The pipe specifications have four wall thicknesses of 17.8 / 21.4 / 25.7 / 30.8mm; the operating internal pressure of the pipe with a wall thickness of 17.8mm is 10Mpa, and the operating internal pressure of other pipes is 12Mpa; various crack sizes have different depth-to-width ratios a / c and The situation of a / t and the situation of buried cracks considering 2a / t are shown in Table 2:

[0067] Table 2

[0068]

[0069] The wall thickness of the pipe used in this example is 21.4mm, the outer diameter of the pipe is 1422mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com